Katie Shaw, chief operating officer of the Open Apparel Registry (OAR), explores the immense potential of open data as the industry faces ongoing challenges in the wake of 2020.

It’s the time of year where industry professionals are working hard to hit the ground running, setting goals, establishing and actioning strategies for the year ahead. Across all industries, if the past 12 months of global uncertainty have taught us anything, this exacerbates the need to be flexible and adapt quickly in the face of constantly changing external environments – consequently, good data to inform decision-making is key. For the apparel sector in particular, data is vital, and in recent years, the industry has begun to wake up to this.

Unfortunately, a crisis is often the catalyst for radical change and this is especially true for the apparel sector. Readers of WTiN will be all too familiar with the tragic details of the Rana Plaza building collapse in Dhaka, Bangladesh in 2013 during which over 1,100 workers were killed. This revealed to the world what many sector professionals had known for a long time: thousands of people worldwide are forced to work in dangerous conditions, with no rights and minimal pay. And at an operational level, it also revealed how little was known by major global brands about their supply chains. While a tiny number of brands were quickly able to confirm whether their products were being manufactured in the building, scores of others simply did not know.

Fast forward to 2020 and the Covid-19 pandemic exposed a different sort of fragility in global apparel supply chains: increased risk from over-dependency on one region for sourcing. The shock waves triggered by the pandemic in the apparel sector have prompted many brands to reconsider their sourcing strategies, whether through nearshoring their supply base or diversifying their sourcing regions. Once again, the importance of high-quality data has become paramount for brands to survive – or even prosper – through the on-going crisis.

The supply chain: a complex beast

Apparel supply chains are complex and even the simplest of products are processed through multiple stages, at multiple facilities, across multiple geographies. And that’s just for one product type. Scale up the steps involved for the thousands of products being produced on a weekly basis by major global brands and the mere task of mapping a brand’s supply chain becomes a gargantuan undertaking.

A crucial additional challenge faces supply chain teams tackling this task: at as basic a level as name and address information, the existing quality of data in the apparel sector is poor. The reasons behind this are varied, including transliteration inconsistencies, a lack of structured address formats in key sourcing regions and the need to work with international character sets. As well as this, the industry often loses sight of why supply chains need to be mapped, considering it a tick box exercise only. As a result, opportunities are missed to increase organisational efficiencies through the smart use of technology and considering how to store and share data.

Current state of play

Following the revelations of the Rana Plaza disaster, a growing trend developed for supply chain disclosure in the apparel sector, spurred on by groups such as the Transparency Pledge coalition and Fashion Revolution.

However, in response to these calls for greater transparency, supply chain disclosure has been inconsistent, difficult to track from one website to another and data is often locked away in non-machine-readable formats such as PDFs or tables embedded in websites. A lack of standard formatting for information (coupled with the poor quality of this data) makes it difficult and costly for anyone to compare across datasets and understand shared connections to facilities. Data is often stuck in silos and lacks a universal, central ID through which systems can synchronise, making interoperability between systems impossible.

As data emboldens as a priority, brands and factory groups alike have become frustrated with the multiple IDs connected to the same facility, used individually by each of the multiple MSIs in the sector. Employees at brands, MSIs and civil society organisations would spend hours poring over Excel spreadsheets looking for duplications, matches and overlaps. But increasingly there are simple ways for an organisation within the apparel sector to disclose data more effectively.

In 2019, a set of recommendations was published to guide industry on how best to record and share data – the Open Data Standard for the Apparel Sector (ODSAS). ODSAS is a simple set of instructions for any organisation to follow, whether they have been disclosing supply chain information for years or are at the beginning of their transparency journey. By publishing data in an open, comparable and machine-readable format, this moves transparency beyond a tick-box exercise into an exercise that will result in greater efficiencies, facilitating interoperability and, ultimately, improved supply chain conditions – both social and environmental.

What is open data?

It’s important to define precisely what open data is, in order to truly understand and harness the benefits it brings. According to the Open Knowledge Foundation, “open data is data that can be freely used, shared and built-on by anyone, anywhere, for any purpose”.

“There are two key elements to openness: legal openness [and] technical openness.

“[While] three important principles of open data are what make it so powerful: availability and access – that people can get the data; re-use and redistribution – that people can reuse and share the data; universal participation – that anyone can use the data.”

Central repositories

Considering all these elements together (the limited understanding of global apparel supply chains, the poor quality of industry data and the hugely inefficient processes deployed by organisations across the sector in sharing the data that does exist), there is clearly a need for a central, neutral repository for data in the apparel sector.

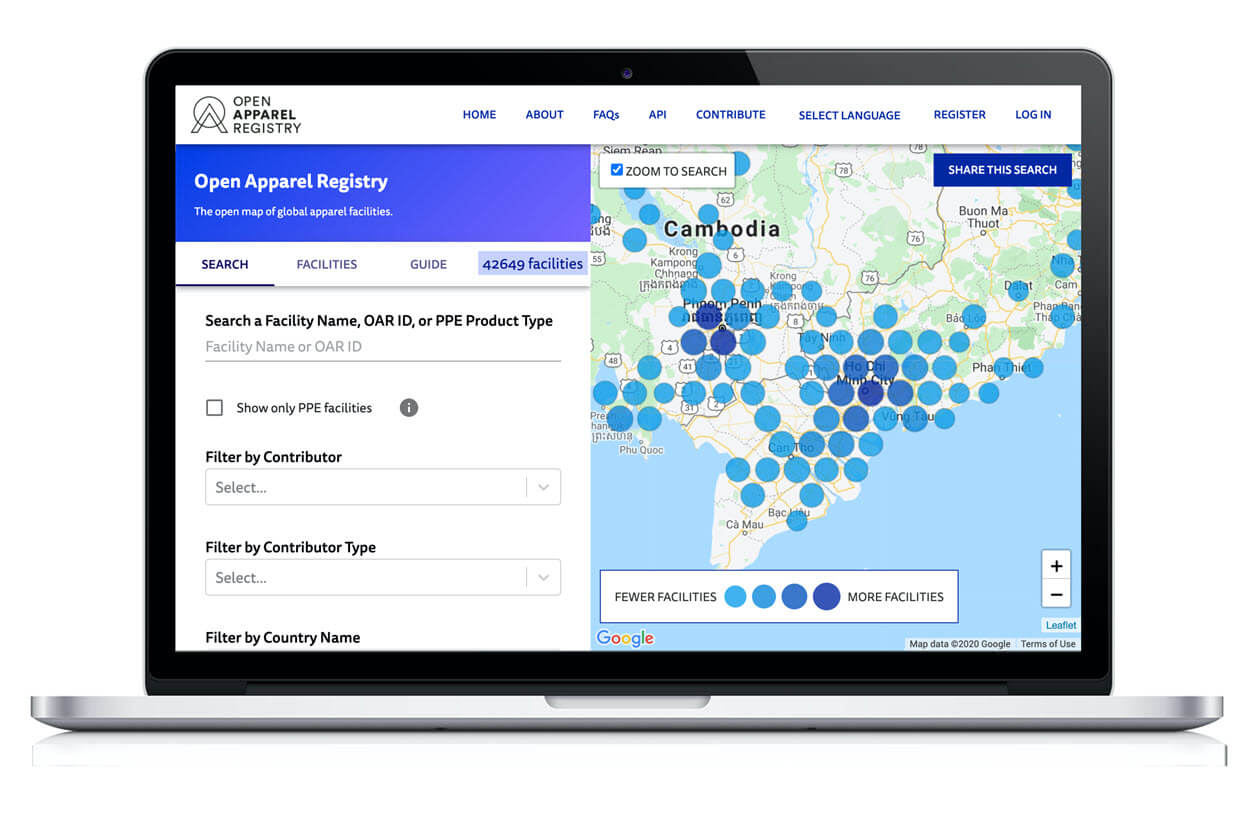

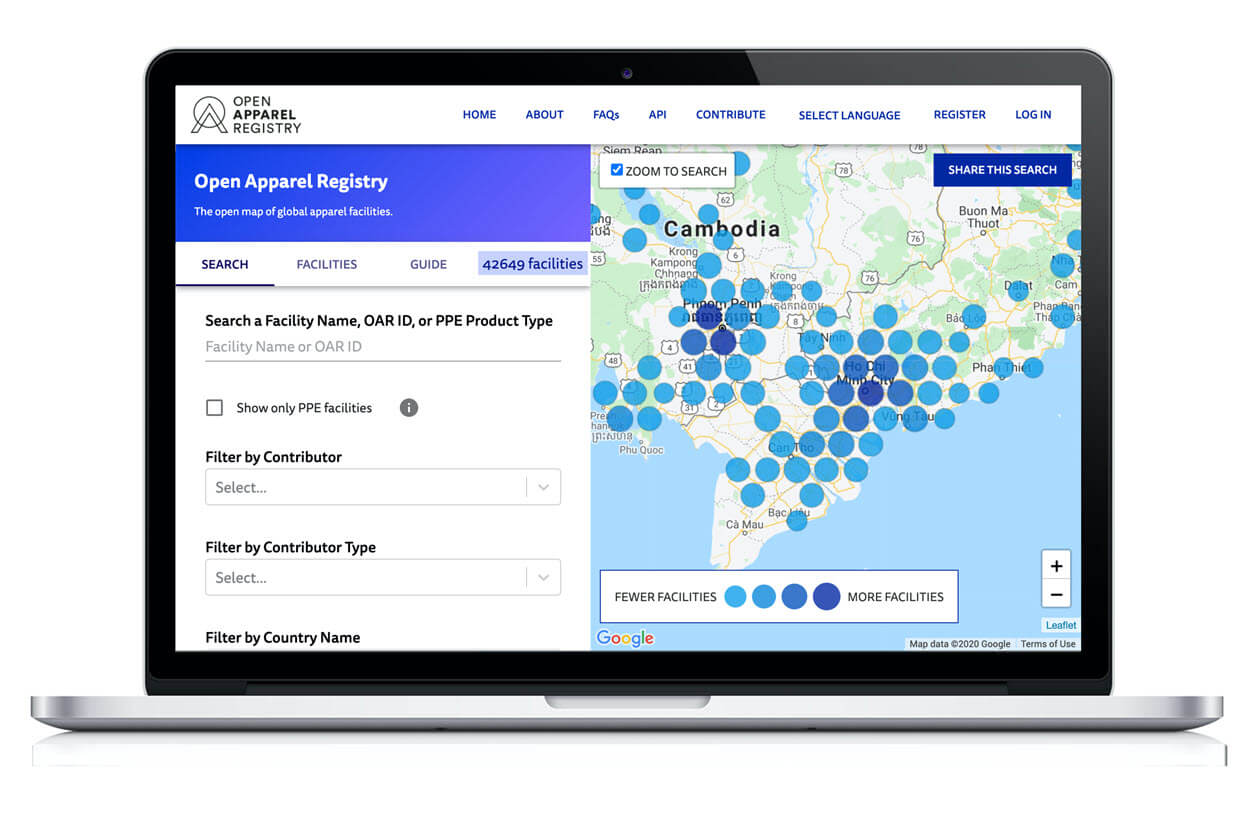

The Open Apparel Registry (OAR), for example, is a neutral, open-source tool that maps garment facilities worldwide and allocates a unique ID to each. Since launching at the end of March 2019, the OAR has grown to include data from major global brands, multi-stakeholder initiatives, civil society organisations and factory groups. The tool is used by stakeholders across the apparel sector to eliminate confusion and facilitate collaboration, enabling interoperability across systems and tackling the long-standing industry problem of facility identification.

Within the platform, an algorithm standardises data from contributors across the industry to create a common registry of names and addresses, each assigned a unique OAR ID number. Working with OAR IDs alongside facility names, the way that contributors are presented on facility profiles and disclose information within a consistent, centralised repository creates benefits for users across the entire sector.

The tool processes all data uploaded to the registry, identifying matches using a statistical model which looks for similarities in the submitted name and address data – combining any duplicates. Additionally, the contributors of the data are visible on each facility profile, so users can see at a glance which organisations share a connection to a facility. This enables in-facility collaborations between organisations, whether that’s groups coming together to work on social or environmental improvements in factories, or civil society using the tool to advocate on behalf of vulnerable supply chain workers.

Overall, interoperable technologies such as the OAR will be the backbone of developing a newly data-rich and efficient industry in the new year. When an organisation chooses to share data openly, in line with the recommendations of ODSAS and through interoperable platforms, the entire apparel sector appears to stand to benefit.

As we welcome 2021, organisations could soon enjoy greater operational efficiencies, driven by access to better quality data. Through an improved understanding of complex supply chains and the ecosystems surrounding facilities, the opportunities for stakeholders to work together towards a more equitable and transparent system for all are endless.

The Open Apparel Registry is a neutral, non-profit organisation, committed to ensuring that any organisation can access better quality name and address information and OAR IDs, for free. Visit openapparel.org to search and contribute data to the tool and understand the benefits open data can bring your organisation.

Have your say. Tweet and follow us @WTiNcomment