Sponsored by Brother

Throughout the Covid-19 pandemic, the digital textile printing industry performed better than other textile printing sectors.

But the market still suffered setbacks: the forced closure of high street brands and retailers had repercussions for both original equipment manufacturers (OEM) and their customers. But these challenges were confined largely to the roll-to-roll sector. In contrast, garment printing technologies have enjoyed unprecedented growth over the last two years and influential direct-to-garment (DTG) printer OEM Brother is reaping the rewards.

“The pandemic has initiated change,” says Brother’s sales & product manager, Heiner Rupperath. “Not least a shift to more sustainable production which can be realised through DTG printing.

“It is true that the textile industry suffered, and the digital textile printing market was no exception to this. However, what has been key to the market’s recovery is its innovative nature which enables a high degree of versatility.”

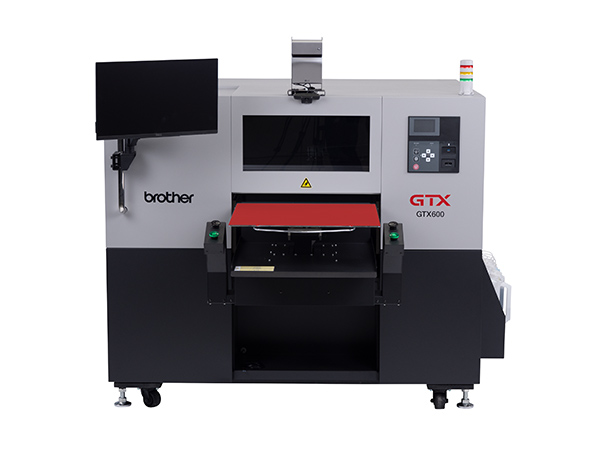

Priorities for Brother when developing new printers are performance, ease of use and versatility. According to Rupperath, these conditions have all been met with the new Brother GTX600. The industrial-grade DTG printer was launched on New Year’s Day (2022) and is the third addition to the GTX family after the GTXpro and GTXpro Bulk.

“Inspiration for the GTX600 came from print service providers who had already implemented DTG technology, some of whom are existing customers,” says Rupperath. “We listened to their needs, which included increased productivity, reliability and flexibility in light of new applications and trends. Therefore, the GTX600 supports sustainability, enables increased uptime and faster print speeds, facilitates simple maintenance and operation and offers improved flexibility and reliability.”

Affordability

But, in what way have these improvements impacted cost? The recommended end user price for the GTX600 is EUR€55,995 which, according to Rupperath, “sits somewhere in the middle of standard smaller machines and high-end industrial printers.”

So, a unique selling point of the GTX600 is its ability to provide industrial print speeds at a fraction of the cost of existing market solutions. What’s more, Rupperath says the GTX600 maintains all the key features of the GTXpro and GTXpro Bulk models, including easy maintenance, usability and flexibility. He summarises: “The GTX600 combines the benefits of smaller flexible DTG printers with the industrial robustness of high-speed machines.”

Rupperath suggests the GTX600 is a response to the growth of the DTG market over the last five years, but it is fair to say the sector has reached another gear during the pandemic with more consumers now utilising ecommerce platforms for fashion and apparel. DTG technology enables bespoke on-demand printing that satisfies the pressures of modern consumerism: personalisation, sustainability and fast turnaround times. The GTX600 accomplishes this, according to Rupperath.

Industry reaction

Early feedback has been wholly positive too. Rupperath says: “The printer is a summary of the latest innovations made by Brother to support mass production and to reduce the burdens of maintenance, as well as potential downtime. Overall, this new equipment was already proven before its official launch on 1 January (2022) —it is made for real industrial production.”

Because of the current demand for DTG technology, Brother received several GTX600 orders before its official release. One field test customer placed an order for 20 machines before Christmas (2021). The GTX600 was showcased at Viscom in Milan and FESPA Global Print Expo in Amsterdam last year, also signifying the importance of face-to-face events.

“Field tests went well,” says Rupperath. “Customers tested the machine for several weeks and they were impressed by its immediate functionality. It was reliable from first use in real-life production environments which is quite unusual for a brand new system. Only small adjustments had to be made and the machine was ready to be launched on schedule. In general, all field test customers stated the GTX600 met their expectations on production speed, reliability, quality output, easy maintenance and flexible handling.”

Market potential

We know that the DTG market is experiencing high levels of growth but, in reality, the sector still only accounts for a small percentage of textile printing output. Nevertheless, Brother is optimistic about the sector’s total addressable market.

“There is potential to serve analogue technology users like screen printing providers in the future [rotary analogue screen printing accounts for the majority of textile printing output globally],” says Rupperath. “But it is important to understand the needs of these customers: colour matching, running costs and easy handling requests, for example.

“We are also witnessing the emergence of new online stores providing web-to-print services, as well as traditional fashion brands looking for local and flexible on-demand production. In general, we see DTG technology being applied to a wider variety of applications, like leather and PET films. Brother is always interested to learn from its customers and expand their possibilities through technological developments.”

For instance, last year Brother modified its GTX printers to facilitate direct-to-film (DTF) printing. The niche market is growing quickly — the printing method originated in China, but WTiN Digital Textiles has received reports from European distributors and resellers that DTF printer sales are increasing rapidly across the continent. It’s another signal that the reshoring movement is gathering momentum as the textile supply chain looks to minimise its reliance on cheap labour markets in the East.

Rupperath adds: “We are seeing the reshoring or textile production back as far as western Europe. The pandemic highlighted flaws in existing supply chains and shifting consumer priorities.”

The profits of companies operating within the digital DTG market have skyrocketed during the pandemic, from OEMs to print service providers, online stores and fulfilment centres. A similar trend is forecast in 2022.

Hastening this movement is a growing desire among consumers for sustainable fashion – purchasing decisions are changing which is forcing businesses to take note.

The environment

Sustainability is an issue that Brother takes seriously, and the use of water based pigment inks in Brother’s printers and across the broader DTG market are cause for celebration. When printing with pigments fewer hazardous chemicals are used and less wastewater is generated. But more can still be done.

Rupperath says: “Better communication and cooperation between universities, textile producers and machine manufacturers is required to define new supply chains and production processes which are both practical and affordable. This is a challenge, but it is one we [Brother] are happy to accept – it is important for all of us. This will result in new technology in the near future and the creation of new Sustainable Development Goal-based (SDG) collaborations.”

In summary, Rupperath understands that digitalisation, sustainability, reshoring and growing consumer needs are all inextricably linked.

“We have received many requests from fashion brands who want to finish textiles more locally,” says Rupperath. “Driving this is a reduction in transportation time and cost. Furthermore, online businesses are growing fast and naturally a lot of Brother’s customers are active online.

“From a chemistry point of view, the awareness of printing with water-based pigment inks and the improved quality output means DTG printers can truly facilitate on-demand, local production. Environmentally friendly chemicals in printing processes and standards like the Oeko-tex Passport or GOTS certification are important for future success and Brother’s inks meet these standards.”

Brother is expected to make another big announcement in April (2022), so stay tuned.