Remo Gorlei, co-owner of South African textile design and print company Imaterial, talks to Madelaine Cornforth about the firm’s investment in digital printing, and South Africa’s current digital print landscape.

Located in Cape Town, the company has been running for 30 years and has been involved in the digital textile design and print industry since 2006. It specialises in roll-to-roll printing for fashion and home textiles, and covers three pigment printing processes -- rotary, flatbed hand-screen and digital. The company prints for a wide variety of both local and international customers, from small entrepreneurs to large retail stores.

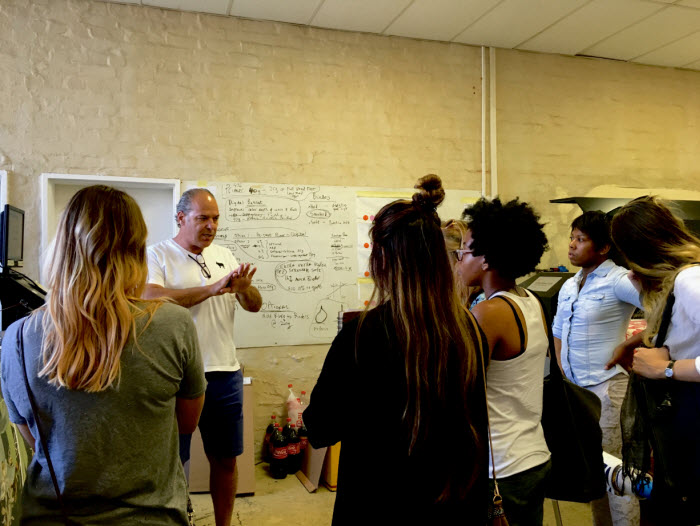

Remo Gorlei, co-owner, Imaterial, explaining the digital print procedure to students

On turning to digital, Gorlei says: “We found we were turning a lot of customers away who had complex designs and needed small runs. We had also built a loyal customer base, so we wanted to improve our service to them.”

So in 2006 the company invested in its first DuPont digital printer, buying its second six years later. It currently has a third digital printer, from a different manufacturer, on order.

According to Gorlei, the company chose a DuPont digital textile printing machine because “it was one of the original and more successful pigment printing machines that came out at the time. You could say they lead the digital pigment printing for some years.

“The machines are still going great but, due to popular demand from our existing client base, we have a new machine on its way,” he continues. “All we can say at this stage is it will be from one of the top digital manufacturers in Italy.

“With all three machines we did months of research and decided to choose from the companies with the best reputation and machines that have been tried and tested,” adds Gorlei. “Digital textile printers are very specialised machines – you cannot experiment with them; they have to be right from word go.”

The company is aiming to have the new printer fully set up in June.

Digital printing

Digital printing has given the company the ability to print more intricate, complicated designs and means that small runs are now feasible. Remo says: “With digital, you do not have any limit to the amount of colours you can use and you have more freedom with repeat pattern sizes. Also, realistic photo images can be digitally achieved on cotton and linen fabrics.”

The company mainly specialises in commissioned printing, so customers create their own designs. Gorlei says that digital printing has definitely helped grow this aspect of the business: “With digital, the customer can bring any design, and it can be printed – unlike screen printing, where there can be restrictions on design, such as repeats, colour and finesse. Since we started with digital, we have rarely not been able to print a design.”

However, Remo notes that the introduction of digital into his business has not diminished the importance of rotary and hand-screen printing. He says: “Rotary and hand-screening will always have its own place and advantages within the textile industry. Part of our success with our digital printing was the research that we put into choosing the correct machine and inks. Digital textile printing is an industry unto its own and must not be confused with graphics.

“Our new digital textile machine is coming from one of the best and most experienced manufacturers in Italy,” continues Gorlei. “We are expecting even faster printing speeds, improved running costs, sharper images, brighter colour and better fastness. The variety of fabric qualities that we will be able to print onto will be phenomenal.”

Digital print with pigment inks from Imaterial

South Africa

The company’s South African location inspires its designs, according to Gorlei. “Cape Town is such an amazing place, and we have so much young and experienced talent in South Africa and, with this, comes natural potential,” he says. “Digital printing has opened so many more doors for us, and particularly helps small entrepreneurs who are just starting out in the industry.”

However, digital printing at the moment is not very big in the country, despite it working for Imaterial. Gorlei says: “At this stage in South Africa, price is still a big issue, so digital printing is not a huge industry at the moment.

“When we started doing digital, we already had many years’ experience in pigment printing. Our digital belt machines are just a smaller version of rotary machines where the screen unit is replaced by digital printheads. The rest is pretty similar.

“There have been companies in South Africa that failed working with digital, as they had no previous experience in textiles,” he continues. “Part of our success is down to our extra knowledge on coatings and finishing of the fabrics, which is a huge advantage.

“When we first invested in digital it was completely new in South Africa. Nobody understood it and our customers were sceptical,” adds Gorlei. “Our biggest hurdle was convincing customers that the finished print was not very different from the conventional screen-print look. However, as time has gone by, our clients have become more accustomed to what is achievable, and have adapted their design accordingly, for digital.

“Although order runs aren't usually big, demand for digital printing is definitely increasing in the country,” he says. “We hope to play a part in the development, and will try to take our digital textile printing to another level with our latest machine.”

For further information visit www.imaterial.co.za.

RELATED ARTICLES

-

Digital sensors support fabric moisture detection

- Otis Robinson

- WTiN

-

Kornit Digital Leicester Made 2025 partnership

- Kornit Digital

- WTiN

-

S&S Activewear signs exclusive agreements

- S&S Activewear

- WTiN

-

News Release

Swiss Textile Machinery Association leadership