The increasingly tough conditions that military personnel and emergency responders are faced with have led to the continuous evolution of smart textiles in military and emergency gear. Government support has created a demand that has helped the growth of the global smart textiles market in these sectors. And, thanks to the work of research institutes, advancements in material science present some exciting possibilities for future protective equipment.

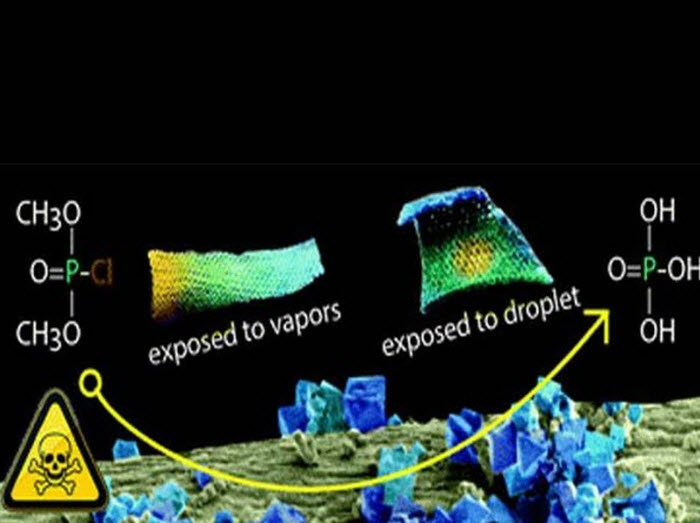

The smart textile developed by the researchers adsorbs, degrades and senses nerve agents

The smart textile developed by the researchers adsorbs, degrades and senses nerve agents

The City College of New York, for instance, has developed smart textiles with the ability to rapidly detect and neutralise nerve gas. The fabric consists of a cotton support modified with Cu-BTX metal organic framework (MOF)/oxidised graphitic carbon nitride detectors.

Chemical engineer and Fulbright scholar, Teresa J Bandosz, who headed up the research, speaks to WTiN about what prompted the experiment. “The ultimate satisfaction for material scientists is that you make something that can be useful,” she says. “So, with this research, the aim was to deposit graphitic carbon nitride composites onto simple fabric to see if they could work, and to contribute somehow to the field of science and defence and personal protection.”

According to Bandosz, the graphitic carbon nitride composites were developed in the lab previously, and tested as nerve agent detoxification media and colorimetric detectors.

Teresa Bandosz led the research undertaken at The City College, New York

Teresa Bandosz led the research undertaken at The City College, New York

Combining Cu-BTC and g-C3N4-ox resulted in a nanocomposite (MOFgCNox) of heterogeneous porosity and chemistry. Upon the deposition of MOFgCNox onto cotton textiles, a stable fabric with supreme photocatalytic detoxification ability towards the nerve gas surrogate, known as dimethyl chlorophosphate, was obtained.

The detoxification process was accompanied by a visible and gradual colour change, which Bandosz says can be used for the selective detection of chemical warfare agents and for monitoring their penetration inside a protective layer.

“These smart textiles adsorbed almost 7g of chemical warfare agent (CWA) surrogate per gram of Cu,” says Bandosz. “The superior performance was linked to the high dispersion of the MOF crystals on the fibres, and a specific texture promoting the availability of the active copper centres.”

When it came to selecting fabrics for testing, researchers were looking for fabrics that were “multi-functional” in order to achieve a “good catalytic phase”. Cotton was chosen for its large surface area. “It has oxygen groups on the surface for the position of our active phase,” says Bandosz. “Plus, the white colouring of cotton helps with sensing.”

Potential applications of the smart textiles range from chemical suits and emergency response and military uniforms, to fabrics covering the actual military equipment, according to Bandosz, who has previously carried out research at the University of Malaga in Spain to help alleviate global warming and solve energy problems.

Further research

Bandosz is now seeking funding for additional research which, she reveals, will experiment with activated carbon fibres. “We found that if we’re able to modify them to deposit our active phase, we could bring more synergistic effects to the performance, as activated carbon textiles are also porous. They present an interface between our catalytic phase to aid performance, while the porosity inside the fibres can help by storing the composition products.”

She continues: “We have broad experience with carbon, so we know how to make it active. More modification of the carbon fibres could bring more activity to the end product which could contribute to the oxidisation of the agents.”

The team also aims to explore other compositions of the active phase. “We would like to find more synergy between the fabric support and the active phase; this is why we’re looking at porous fabrics,” says Bandosz.

The study appears in the journal Nanoscale Horizons.

Have your say. Tweet and follow us @FHaran_WTiN and @WTiNcomment

RELATED ARTICLES

-

Fashion For Good launches new tool

- Fashion for Good

- WTiN

-

Wool Market Report

- Nitin Madkaikar

- WTiN

-

Archroma awarded EcoVadis Gold rating

- Archroma

- WTiN

-

News Release

BW Converting promotes sustainable finishing

-

News Release

Patagonia releases first progress report