The fashion & apparel industry is full of inefficiencies and has been criticised for pursuing some environmentally damaging trends and business models throughout the last decade – the most controversial of which has been fast fashion.

But now that consumer buying habits have begun to shift in response to a growing awareness for the environment, brands and retailers of all sizes have started to take action and many are looking to technology for an answer.

This developing trend has resulted in the emergence of companies such as meepl, a Switzerland-based enterprise that has developed three services: Made-to-Measure; Size Recommendation; and Virtual Fitting Room.

The aim of meepl, according to the company’s vice president EMEA René Stampfl, is to “put the end consumer at the core of its services, connect them directly to the fashion and apparel market and ultimately create a more sustainable industry”.

meepl’s 3D body reconstruction technology is integral to its trio or services. Stampfl says: “Our 3D body reconstruction platform enables everyone with a smartphone to easily, and in real-time, create their own body profile. That body profile consists of a 3D avatar and over 50 body measurements. The measurements are then calculated automatically in a standardised way from the virtual body.

“We have built specific services that are tailored to the apparel industry around this central body profile,” adds Stampfl. “The fashion & apparel industry is one of the most environmentally damaging and wasteful industries, but we are trying to solve a lot of those problems with our services which are centred around the end consumer.”

Through Made-to-Measure, meepl clients are able to access accurate measurements without the physical presence of the customer. This is because the technology’s accuracy is to a standard that means it is no longer necessary to manually measure the consumer, according to Stampfl. And because a large quantity of clothing is discarded or returned because of issues around fit, it is hoped that this technology will extend the length of time in which a consumer is satisfied with their purchase and therefore reduce the amount of clothing that goes to landfill.

The measurements are generated through meepl’s mobile 3D body scan technology. By creating a meepl profile, the company says that state-of-the-art deep learning methods extract more than 50 accurate body measurements from the 3D body scan. If desired, additional customer-specific measurements can be provided in order to achieve optimum fit. According to Stampfl, these measurements are immediately sent to the garment manufacturer’s pattern grading CAD or knitting systems and used to begin instant custom-fit garment production.

Similarly, Size Recommendation also aims to reduce the number of returns that retailers endure. It does this by ‘removing the guesswork’ when it comes to choosing garment sizes. Instead, it enables consumers to ‘find their best fit at the click of a button’. Stampfl adds: “meepl’s Size Recommendation technology achieves this through machine learning techniques to combine clothing data with body measurements which derive from the customer’s very own meepl profile.”

meepl understands that every garment has its own unique fit and size recommendation, yet data for this is often generalised throughout an entire collection. Stampl continues: “Size Recommendation is based on the individual measurements of a specific customer using either the full meepl profile, which requires a body scan, or the meepl quick size function.”

The meepl quick size function, unlike the full meepl profile, does not require a body scan. Instead, meepl asks for a customer’s four key body values: gender; age; height; and weight. Once the customer’s quick size has been calculated, their specific sizes will be displayed automatically within online shops.

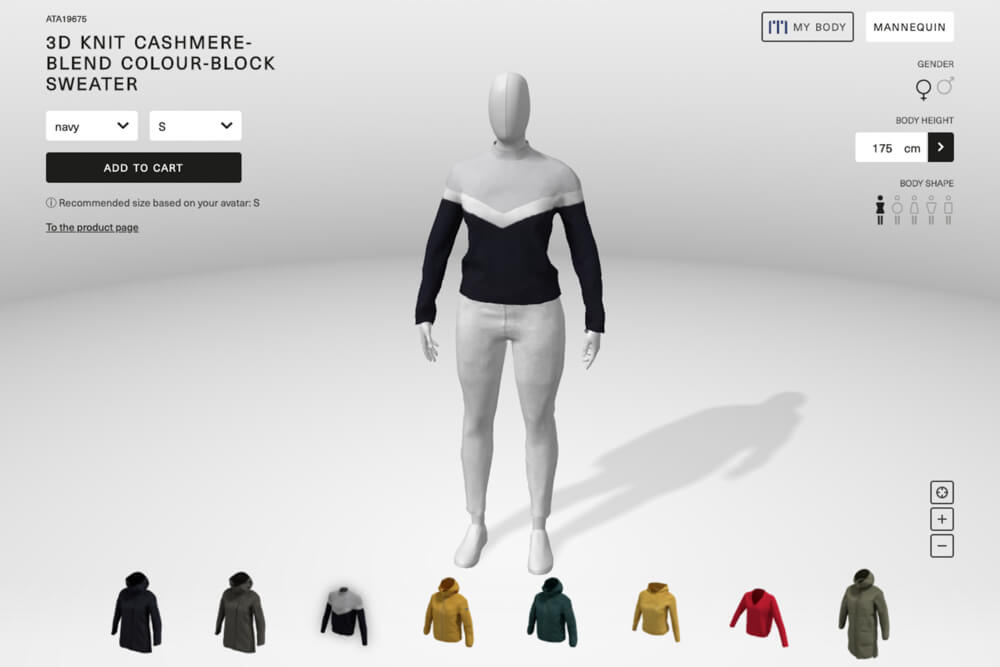

That brings us to the last of meepl’s three solutions: Virtual Fitting Room. The technology, which utilises visual computing and 3D garment assets designed with 3D CAD software, according to Stampfl is “an end-to-end solution that improves efficiencies during the design and sampling processes and visually communicates 3D content in consumer-facing channels like online shops”. This results in faster speed-to-market, improved conversion rates and reduced costs, Stampfl adds.

Bespoke products

meepl has only been in existence for four years but has enjoyed early success by targeting emerging trends within the fashion and apparel sector – the biggest of these is personalisation. meepl quickly identified that there is more to personalisation than someone’s initials being printed onto a garment.

It is true that consumers are growing tired of the lack of choice on the traditional high street; items in popular retail stores may be cheap, but they are also accessible to millions of other shoppers around the world. Individualism, which is closely linked to personalisation, has therefore blossomed throughout the last decade and, like personalisation, is a trend that high-street retailers have failed to accommodate.

Analysts do suggest that a lack of personalisation is responsible for the shortening lifespan of a garment. Statistics suggest that people simply get bored of the product, but there is more to personalisation than a unique print or motif.

meepl believes the key to enhancing consumer satisfaction is providing the right fit. No two people are the same, yet for decades the fashion & apparel industry has been designing products based on human averages. The aim was to appeal to the masses, but in reality their sizing suited just a small minority of consumers.

By purchasing a product that fits correctly, both comfort and appearance are enhanced. These are two key considerations when purchasing an item of clothing.

But meepl isn’t just targeting small start-ups, the company aims to transform high-profile retailers and the implementation of disruptive technology will play an integral role throughout. The added benefit of targeting larger organisations means that meepl’s attempts to create a more sustainable fashion & apparel market will be more profound and Stampl believes that meepl’s ideologies are already starting to bear fruit.

He says: “In our opinion, the market is moving further and further away from fast fashion. I think the industry is going to adopt a microfactory-driven approach in the future. There are microfactories across multiple countries where it is simple to produce made-to-measure garments, and the fact that these are produced very close to the end consumer means that the logistics are simplified and have become much more efficient.

“We are doing proof of concepts with global fast fashion companies. We are working together with other partners to tackle the issues facing the industry and produce made-to-measure, customised garments on a very scalable level to meet a greater demand and make the fashion and apparel industry more sustainable.”

Challenges

Nevertheless, meepl isn’t without challenges of its own. Inevitably, as the digital revolution continues to tighten its grip on all aspects of our lives, users are becoming more aware of how their personal data is used. But Stampfl adds that GDPR is something that the company also takes very seriously. He says: “We handle personal body data and so it goes without saying that GDPR compliance is one of meepl’s core priorities. We are always 100% transparent with what is happening with the data, with whom we share the data and give insight into specific queries from customers regarding its flow.”

But Europe, according to the World Health Organisation (WHO), is the current epicentre of the coronavirus pandemic which has decimated the global economy. The virus is the biggest challenge currently facing both innovative and traditional businesses. Well-established organisations have already had to make difficult decisions in order to survive and more are likely in the months ahead.

But despite being an infant company, Stampfl remains optimistic about meepl’s future. “We have experienced a growing demand for our software solutions. With the coronavirus limiting social interactions, tailors and made-to-measure businesses are now looking for technology to remotely acquire their client's body measurements.

“We have also observed that large brands and retailers are recognising the importance of their ecommerce channels and they’re now actively contacting us regarding new ways in which they can make their ecommerce sites more user-centric. They are particularly interested in our Virtual Dressing Room, which enables users to virtually try on clothing in different sizes on their own 3D avatar.”

And for those looking for positives, some analysts believe that the coronavirus pandemic will have reduced the time it takes for the broader textile industry, which has customarily opposed change throughout the last two decades, to wholly embrace the digital transformation so that they will be better prepared for such a devastating event in the future.

Stampfl concludes: “Fashion is getting ready for innovative technologies and fashion tech will become a central element of the apparel industry in the future.”

Have your say. Tweet and follow us @WTiNcomment