The founder of Footfalls & Heartbeats, Simon McMaster, meets with Jessica Owen to talk about the company's smart textile sensor and fibre optic technology.

In Nottingham, UK, based in the building where ibuprofen was first discovered, Simon McMaster and his team have developed a revolutionary and proprietary process for manufacturing smart textiles where the fabric itself is the sensor.

“I thought this up 17 years ago. I was doing a degree in chemistry and nanotechnology at the Open University and at the time I had a café in Bristol. One day, at four o’clock in the morning when I was baking muffins, I thought ‘hmm, I wonder if I could do this’,” McMaster says.

After a few months of consideration and another 10 years of his own time and money, going on various courses to work out how to develop this process, Footfalls & Heartbeats was eventually created.

The company was first set up in New Zealand back in 2011/2012, where McMaster is from originally. After a while, he began talking with a few guys at the University of Nottingham and then moved the company to the UK.

In December 2016, Footfalls moved into the Ingenuity Centre at the university and it was just McMaster and one other employee. Since then, the company has moved again to BioCity, still in Nottingham, and has grown to 12 people.

Knitting with conductive yarns

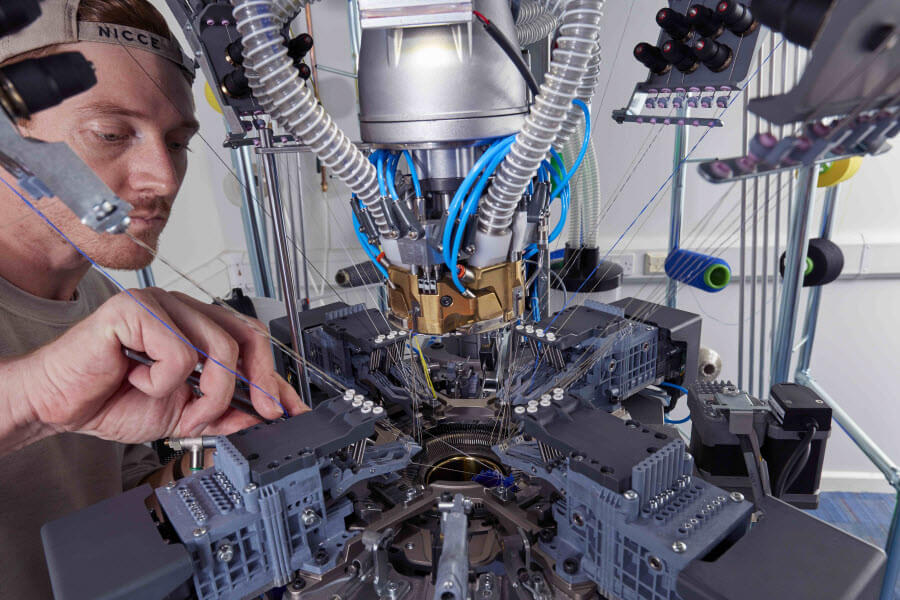

Footfalls has the only Santoni X knitting machine in the UK, one of only 14 in the world at the moment.

“We were the first people in the world to see the machine, apart from the Santoni engineers. My colleague Fern and I went to visit it in Christmas 2017,” he explains.

“The machine knits socks for us and also knits shoes. It knits the uppers and all you need to do is close the toes, put glue on it and stick it to the sole. You can even knit them with the lace lines in them so you can put the laces straight in and then your shoe is done.”

The Footfalls & Heartbeats' technology combines mathematically determined textile structures using electrically conductive yarn to form a repeatable and sensitive sensor network. The technology uses the three-dimensional complexity of a textile structure, including interactions of fibres within the yarn itself, to control the electrical resistance characteristics of the sensor structure.

“The silver coloured yarns are a silver-coated nylon and we also have stainless steel yarns, which are used for the sensors,” explains Byron Salisbury, a knit prototype engineer at Footfalls & Heartbeats, who gave me a demonstration of how the machine works.

“All the yarns get fed through the tensioners that are controlled. There’s a circular four-inch drum and around the edge there are 144 needles. Where the yarns come down, there are fingers that when they are up, they don’t knit, and when they are down, they do.

“It’s just a pattern of them going up and down at certain times and it knits from the cuff to the top of the sock in one go,” adds Salisbury.

The pressure sensor socks look like a normal pair of socks with a series of gold and grey lines and squares on them, which are the sensors. To knit a pair of Footfalls’ socks, it takes around 15-30 minutes, depending on sock and sensor complexity.

At the moment, there is no set price on the socks, but McMaster says they will cost around £40/50, but it depends on what you want to do. For example, a really simple set of socks with just two or three sensors will be cheaper than a pair with more technology.

To power the socks, batteries are required, and other electronics are needed to collect, and wirelessly transmit the data as well. Footfalls has created an interface between the electronics and the sock, and the team has got the electronics down to a size of 35 sqmm.

Socks, steering wheels and seat covers

“The primary aim of Footfalls is to make stuff less invasive. It’s literally just the textiles that you would normally interact with.

“There’s a statistic that you come into contact with textiles 95% of the time you’re on Earth, and so textiles are just perfect for integration with this technology,” says McMaster.

At the moment, Footfalls is focusing on two products – socks with integrated pressure sensors and a large pressure mapping device.

The socks can be used to measure things like someone’s gait. If someone has had a hip replacement, the socks can be used to measure the gait before and after to check if a difference has been made and to monitor recovery and progress.

“We can put it in car seats too. At the moment, air bags in cars are turned on or off by switching a button. With our car seat covers, you wouldn’t need to depend on a button as the cover can detect the size of the person in the front seat to know whether the person’s airbag needs turning on.”

Aside from pressure sensor technology, the company is also working with fibre optics.

“We have a guy who works here called Professor Stephen Morgan who is the professor of biomedical engineering at the University of Nottingham and he does a huge amount of work with fibre optics.

“Now, we are incorporating fibre optics into the textile as well, which gives us a huge amount of functionality.”

With this development, Footfalls can measure absolute pressure down to +/- 100 pascals (that’s the same as a fly running across your skin), heart rate and SPO2 to measure blood oxygen levels.

“It does this with light. Usually in hospital you wear a clip on your finger to measure oxygen, it fires a light through your finger and gathers the light that comes out the other side. Instead of us doing that, we integrate the fibre optics into a textile wristband.”

McMaster says that these devices can also measure things like CO2 in the atmosphere, humidity and temperature.

Footfalls also works a little bit with nonwovens. The company can make a pressure sensor that is applied underneath a bandage to treat venous leg ulcers.

“With compression therapy, normally there is no way of really knowing if you’ve applied the correct amount of compression, but we’ve made an absolute pressure sensor that is able to measure that.”

As McMaster says, the applications are endless. But instead of making every product that is possible, Footfalls is creating a license model.

“We want to license the technology to various companies in various sectors – we’re not going to make them all, that would be a very poor use of our investors’ money. We are going to make all of the prototypes though.”

"Be bold, be brave, have fun and change the world"

“We have this saying at Footfalls – be bold, be brave, have fun and change the world. And that is basically all we are trying to do,” says McMaster.

“Especially with the medical stuff, we could save healthcare systems a lot of money. America has a huge system and it’s ridiculously inefficient – I think they spend around US$3.4tn a year on health, and around 30% of that is unnecessary.

“We just want to help people save money, and as the population is getting older, those parts of the system that could be done at home we could make happen. If I could make someone’s rehab three weeks less, then that's something.”

How the technology would work depends on the application. For example, if a doctor is using the wristband to monitor a person’s oxygen levels and blood pressure, the data would be sent back to the doctor. If the purpose of the technology is for fitness, such as heart rate while exercising, then the data could be transmitted to an app on a smartphone.

“Medical stuff should probably go back to your GP, there’s not a lot of point sending it to you. I saw something on the internet where a doctor had put a frame on his wall that said: ‘Do not confuse your Google search with my medical degree’, so that’s why it should go back to the doctor. For fitness stuff, then absolutely it should go back to your phone,” McMaster says.

The way the NHS works means that it would not directly buy products from Footfalls. So, the company has just started conversations with the Nottingham Care Partnership to start building some work with them.

Finding talent and business partners

McMaster has had his fair share of ups and downs when it comes to Footfalls, including being fired from his own company once.

“Back in New Zealand, I was fired for about three weeks, that was a goodie. Basically, they thought they could do it without me and so I was like ‘alright go for it’,” he explains.

Other challenges that he lists include finding good venture capital investment and talented people to work with.

“The best thing about my job is probably working with all of the people. They’re just brilliant, I just sit in the corner of the room thinking of silly ideas and they just try and make them work. But the hard thing is getting that talent.

“It took us a while to get hold of James (an electronic engineer at Footfalls), electronic engineers are really tricky to find. Textile engineers are impossible too because the industry left the UK and now nobody is trained in it.”

The next challenge for Footfalls is finding a new premises. The company would like to move in order to gain some new equipment such as a seamless x-bed machine from Shima Seiki and a WHOLEGARMENT seamless knitting machine.

The current knitting lab is at BioCity, but “our long-term aim as we expand is to find a location in the historic heart of Nottingham's textile industry,” says McMaster.

Salisbury adds: “It would be great to find an old textile mill that needs a bit of love and the government or council could help.”

"Smart textiles will be bigger than mobile phones"

Footfalls & Heartbeats is not the only company to innovate in the smart textiles sector – McMaster mentions companies such as Sensoria, Hexoskin and Smart Life who are developing similar products.

When asked when smart textiles will become apart of every day life, McMaster reckons it will be in the next three to five years.

“If you take cars as an example, at the moment we’re at the Model T Ford stage (the first mass-produced automobile). For cars, it took 100 years to get to the new Audis around today, but for smart textiles, I don’t think it will take more than 10 years to get there.”

He also believes that certain smart textiles will be a much bigger business than mobile phones.

“Smart phones are a trillion dollar a year business, smart textiles will trounce that by miles, because we all wear clothes and interact with textiles.”

Inspiration from the Grand Canyon

McMaster came up with the name Footfalls & Heartbeats on a trip to the Grand Canyon in the US.

“My younger brother is one of the best white water rafting guides in the world and I went on a trip with him for two weeks while I was at the Open University.

“One day, when the others on the trip went for a walk to explore one of the other little canyons, I stayed behind to do some work as I brought my textbooks with me.

“I decided to get up for a wander and all I could hear at the time was my own footfalls and my own heartbeat and that’s where the name came from.”

Samples of Footfalls & Heartbeats’ products will be on the Santoni stand at ITMA Barcelona in June.

Have your say. Join the conversation and follow us on LinkedIn