Made2Flow creates validated impact measurement solutions for the textile & apparel industry. Tal Shogol, CEO, and Atnyel Guedj, chief product officer, explain more to Jessica Owen.

Stop greenwashing and start measuring – that’s the message that technology start-up Made2Flow is trying to convey.

More specifically, the brains behind the company believe that the textile & apparel industry must move away from impact calculations that are based on generalised averages of raw materials as these ignore the vast differences in facilities and processes across the tiers in the supply chain and lead to misleading claims.

“The fact is that the impact is within the processes across the supply chain,” says Shogol. “It’s not just about the raw material.

“For example, you could have two BCI cotton products – one will reduce CO2 emissions by 20% and the other by 40% compared to the baseline of conventional cotton,” adds Guedj. “And this is because the facilities might be either old or state-of-the-art, or the growers grow the cotton differently. The conversation in the industry is oversimplified and we need to argue these numbers to drive impact faster.”

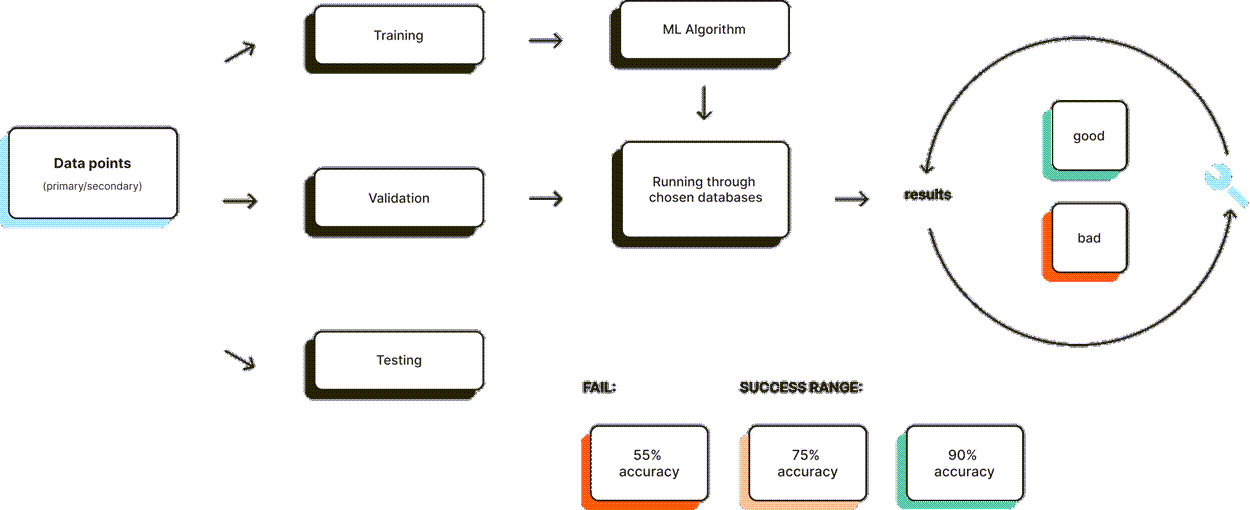

With that in mind, the Made2Flow team has created a proprietary machine learning (ML) technology to provide Measurement as a Service (MaaS). This automated system enables brands to measure their impact, trace their supply chains, measure progress in line with set targets and much more.

The methodology behind the technology is five-fold, and the process starts with using available product and facility data streams from existing datasets such as PLM software or from existing spreadsheets such as tech pack or line sheets.

The second step focuses on validating this data – which is done by calculating an accuracy rate for each data point to ensure that only credible data is in use.

The third step conducts a data gap analysis to study existing, unvalidated and unutilised data and to normalise data to stock keeping unit (SKU) level.

Fourthly, data is collected in an automated and seamless manner from the supply chain (tiers 1-4 in accordance with ISO 14040 (the standard that describes the principles and framework for life cycle assessment). The data is completed using both primary and suitable secondary data. Lastly, environmental indicators such as water depletion or greenhouse gases are calculated and benchmarked according to the life cycle assessment methodology.

“The process is fully automated and seamless, allowing the brands to concentrate on the product,” the pair explain.

Automating the complex process is what is key here to enable impact measurement on a large scale with accurate results. For example, when validating raw data, Made2flow uses a unique multiple source approach. The proprietary algorithm compares large sets of data against its vast databases to calculate accuracy rates (using Bayesian mathematics) to determine if the data at question can be used. This process would take days to complete but with the ML based solution it is done on the spot.

“But honestly speaking, it’s the data validation and data transparency that are challenging,” they say. “The larger companies have large datasets, and they may have thousands of SKUs, so that’s complex and a big challenge. You can understand why other measures in the industry always come under such criticism.”

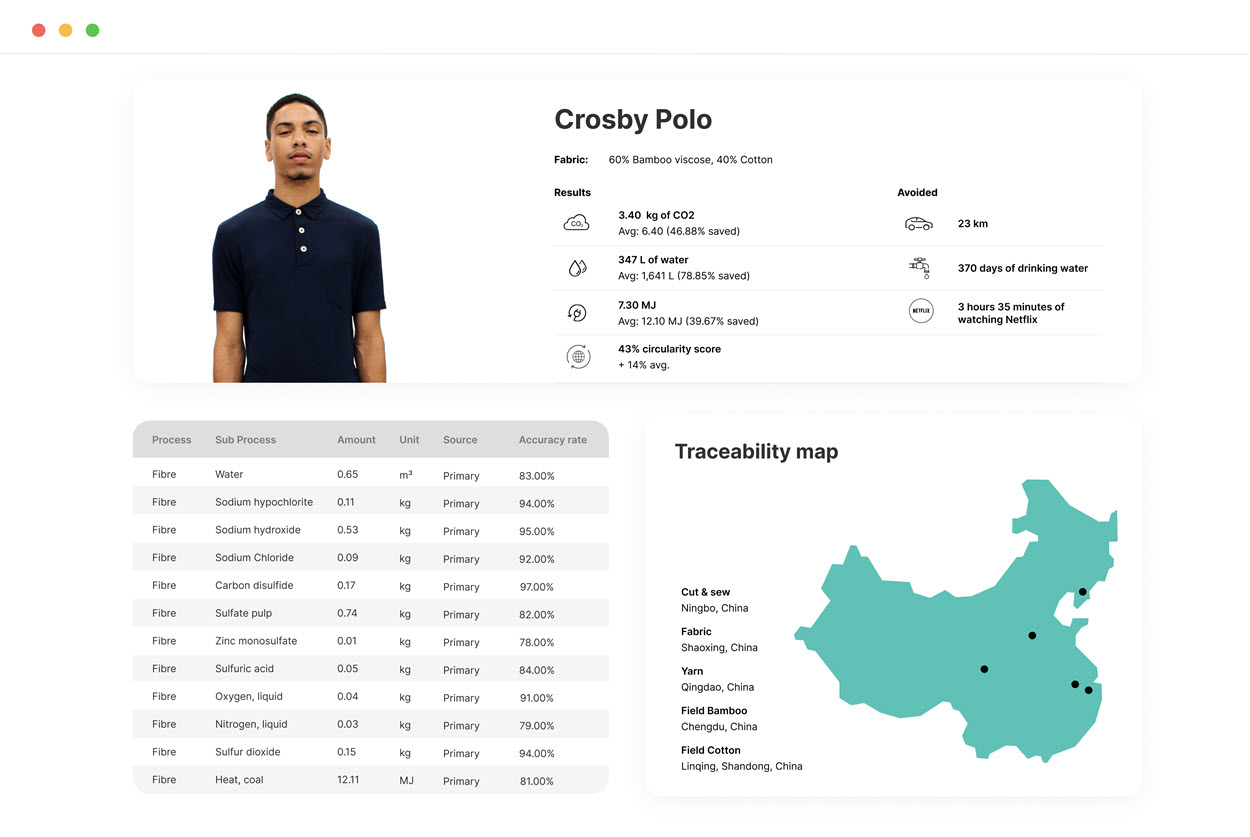

If like me you found all of that information quite overwhelming at first – don’t worry. The Made2Flow team creates visuals, reports, and contextual examples for its customers so that they can digest the data and final results. For instance, the company translates CO2 emissions into how many kilometres that is driven in a car, or it relates it to volume by putting it in terms of cans of Coke or elephants.

“It takes some effort on our part to try and mediate the science to people and brands,” says Shogol.

As mentioned, Made2Flow’s system has several benefits. Besides the environmental and social benefits, brands can market their improved integrity and values – something that consumers are becoming increasingly more conscious about. This should lead to increased sales from accelerated value-based consumption. Elsewhere, the tool can be used to calculate and analyse the impact of decisions at category or product level to make better decisions or facilitate the adoption of preferred materials. What’s more, it enhances supply chain traceability – something that proved key in mitigating risk amid the Covid-19 pandemic.

“If you want to mitigate risk, you really need to understand what’s going on with your suppliers and sub-suppliers in real time,” says Shogol.

Guedj continues: “We once talked to a relatively large company and it thought that most of its supply chain was based in Bangladesh as the majority of its tier one suppliers hailed from there. But after deploying our technology and uncovering its supply chain beyond tier one, we showed them that in reality the company relied heavily on China for its raw materials and fabric manufacturing.”

Shogol adds: “Covid-19 really did amplify companies to start taking action; start taking ownership of its supply chains. We are now seeing that big companies are disclosing this information one by one.”

So far, Made2Flow has measured 1,240 supply chains, collected over 1.2 million primary data points, and helped companies across 21 countries. It’s getting requests from factories across the supply chain, not just brands, about measuring their impact because they’ve realised that transparency is more attractive to potential partners because of the sustainability movement that is underway. So, it’s not only about doing the right thing by the environment or people anymore; validated impact measurement is becoming something that can help businesses to become more competitive.

“At the end of the day, there is a lack of standardisation in the industry when it comes to impact measurement, and we believe that the ultimate answer is to be completely transparent,” says Shogol.

To find out more about Made2Flow, visit www.made2flow.com

Have your say. Join the conversation and follow us on LinkedIn