Kornit Digital provides insight into its relationship with UK-based Shirtworks and explains the reasons why the print service provider chose to implement digital direct-to-garment (DTG) technology.

“Direct-to-garment [DTG] technology is now a solution for lower volume garment printing that would traditionally have been screen printed,” says Arron Harnden, managing director, Shirtworks.

Oxfordshire, UK-based Shirtworks services brands and consumers on five continents and offers a wide variety of personalised apparel and workwear, including sportswear, sweatshirts, caps, jackets, childrenswear, and other pieces.

“Shirtworks supplies decorated garments to all industries,” says Harnden. “We have a very diverse customer base, from consumers ordering one-offs to small brands and ethical-conscious business-to-business [B2B] enterprises needing up to a thousand pieces or more. We are known as an ethical decorator, GOTS-approved for both screen printing and embroidery.”

Success story

Shirtworks’ operations in 2021 are a far cry from its humble beginnings four decades ago. In the 1980s, Shirtworks began by selling screen-printed T-shirts locally to Oxford University students and tourists. In 1996, the company became one of the first screen printing businesses to use a website. In the decades since, Shirtworks has grown to meet the challenges and opportunities of a tech-native, interconnected world, and their success as a growing apparel fulfiller reflects their commitment to innovative technologies and responsible business practices.

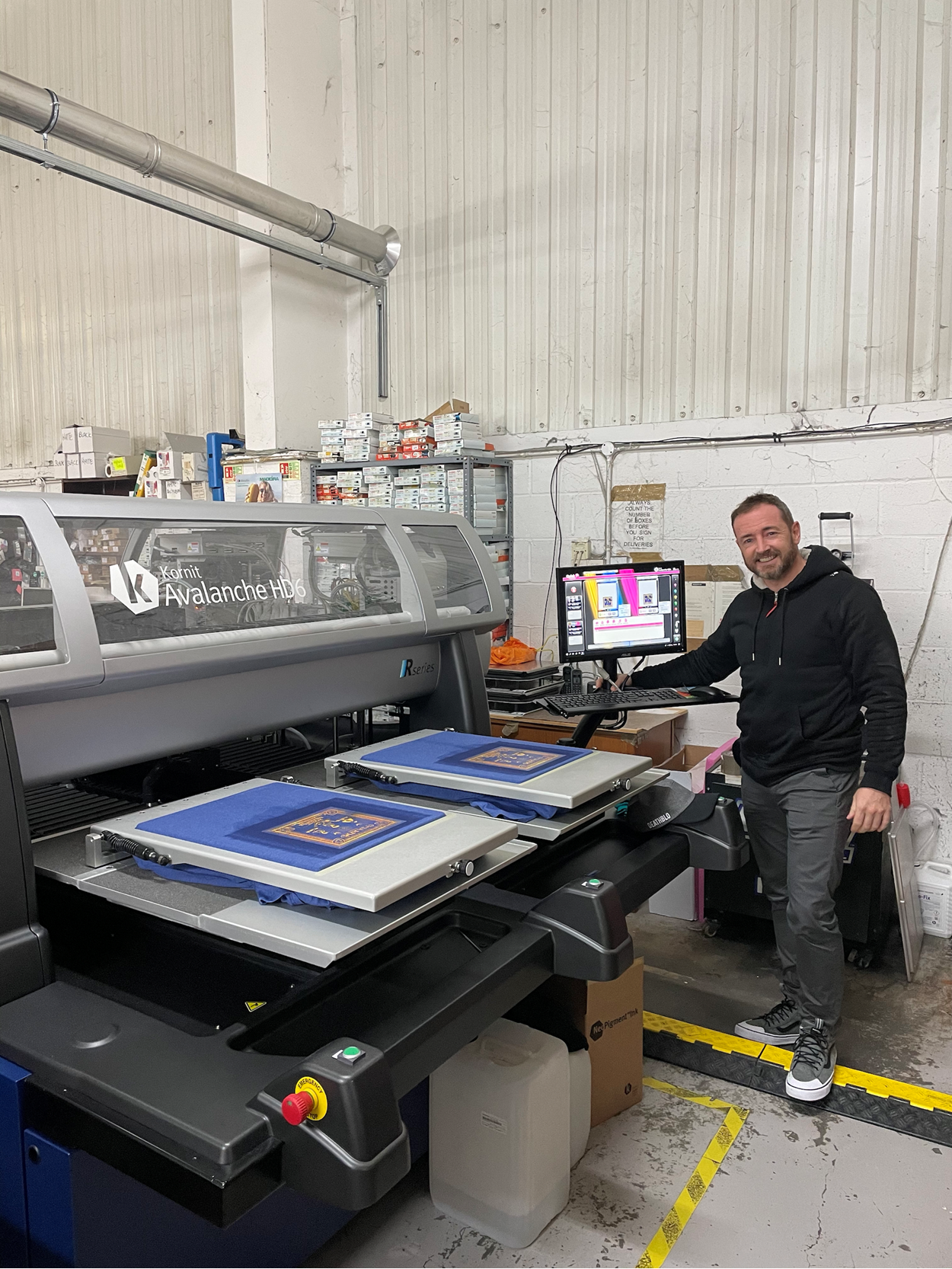

To boost competitiveness in an evolving and increasingly competitive textile printing environment, late last year Shirtworks invested in Kornit Digital’s Avalanche HD6 solution. The machine isn’t Shirtworks’ first experience of digital DTG printing but it is the most positive, comments Harnden. Having supplemented its screen-printing capabilities with embroidery, Shirtworks implemented its new industrial HD system to achieve “sustainable, on-demand fulfilment in a manner that meets its quality standards and is profitable in all quantities.”

“We’ve had an alternative DTG machine, but it couldn’t match the cost-efficiency of screen printing,” he adds. “We expect the Kornit system to help reduce our wage costs, while meeting the very high-quality control standards necessary to maintain strong customer service.”

Kornit Digital’s DTG technology uses a proprietary single step print process and eco-friendly pigment inks that produce no wastewater, imprint a variety of fabrics at the push of a button, and deliver vibrant, photorealistic digital impressions with a durability for wash, rub, and light fastness. As the system requires virtually no setup time or labour, print costs are low and consistent, making runs profitable from the first piece, simplifying the production of samples, and making any design specifications repeatable with precision, the Israeli-based OEM explains.

“We turned to Kornit Digital because [the company] offers a one-process solution, and its inks are GOTS-approved which is very important to us,” adds Harnden. “Being able to match pantones is also very important to us, and key to moving our screen-print clients over to DTG. We also wanted a retail-ready product that would enable us to expand into drop shipping.”

To read the full case study, click here. And if you would like to find out more on how your business can prosper with digital textile printing, download Kornit Digital’s free e-book: Screen vs Digital Textile Printing.

Have your say. Tweet and follow us @WTiNcomment