Sandler makes further progress on its sustainability journey

By Katharina Obergruber

Sponsored by Sandler

German nonwovens manufacturer Sandler is connecting the puzzle to pave a way towards a circular economy. By Katharina Obergruber, sales manager for Transportation Products and project manager for Greenology at Sandler.

Sustainability has become the buzzword in almost all areas of our lives. While often reduced to developing biodegradable products, its meaning encompasses any measure or initiative geared towards conserving resources with a view to maintaining the world we live in – from economic, social, as well as environmental perspectives.

Nonwovens manufacturer Sandler says it has always put high emphasis on sustainability in all its contexts. Lowering resource consumption and reducing the carbon footprint of its nonwovens continues to be the focus on the path towards a sustainable future.

Connecting the puzzle pieces

Sustainability refers to numerous aspects of company activity and experience has shown that it cannot be achieved through a single initiative.

In the context of product development, sustainability is only achievable through a synergy of technology development, raw material development and product development, carried out in close cooperation with customers and partners along all stages of the value chain. Each initiative and each new step taken forms another piece of a puzzle, complementing an ever-growing picture of sustainable product solutions.

Sandler is following this approach, continuously expanding its #sandlerpuzzle campaign. In this context, sustainability is very much a question of the specific application or end use. Each application is characterised by product specifications set out by manufacturers as well as laws and regulations influencing product design and the choice of raw materials. As with sustainability itself, there is no single ‘right’ solution. In each target market, the term ‘sustainable alternative’ means something different. Evaluating available alternatives and finding the right solution for the use case in question is key.

In the case of nonwovens, sustainability discussions often centre on the raw materials used. Sustainable alternatives in terms of fibres or granules can be found in both natural resources and recycled raw materials. In this sense, offering 100% sustainable products is possible even today. At Sandler, one third of the raw materials purchased are from sustainable or recycled sources. And about one fifth of all fibre blends already contain recycled fibres or fibres based on another naturally sustainable source. Sandler offers sustainable solutions for specific applications but puts a high emphasis on continuing the search for alternative raw materials and the development of more sustainable product solutions.

In evaluating the alternatives available, Sandler has developed a scoring matrix based on application requirements. Across different departments – including purchasing, product development, production and logistics – information on available raw materials, manufacturing technologies and feasible transport methods are collected. Here, different combinations of these factors are evaluated and assigned a rating, creating a basis for informed decisions. This scoring matrix is flexible and takes all facets of product development and manufacturing into account. It provides a useful tool in further advancing sustainability measures and looking for the next piece to expand the puzzle.

Sustainability through circularity

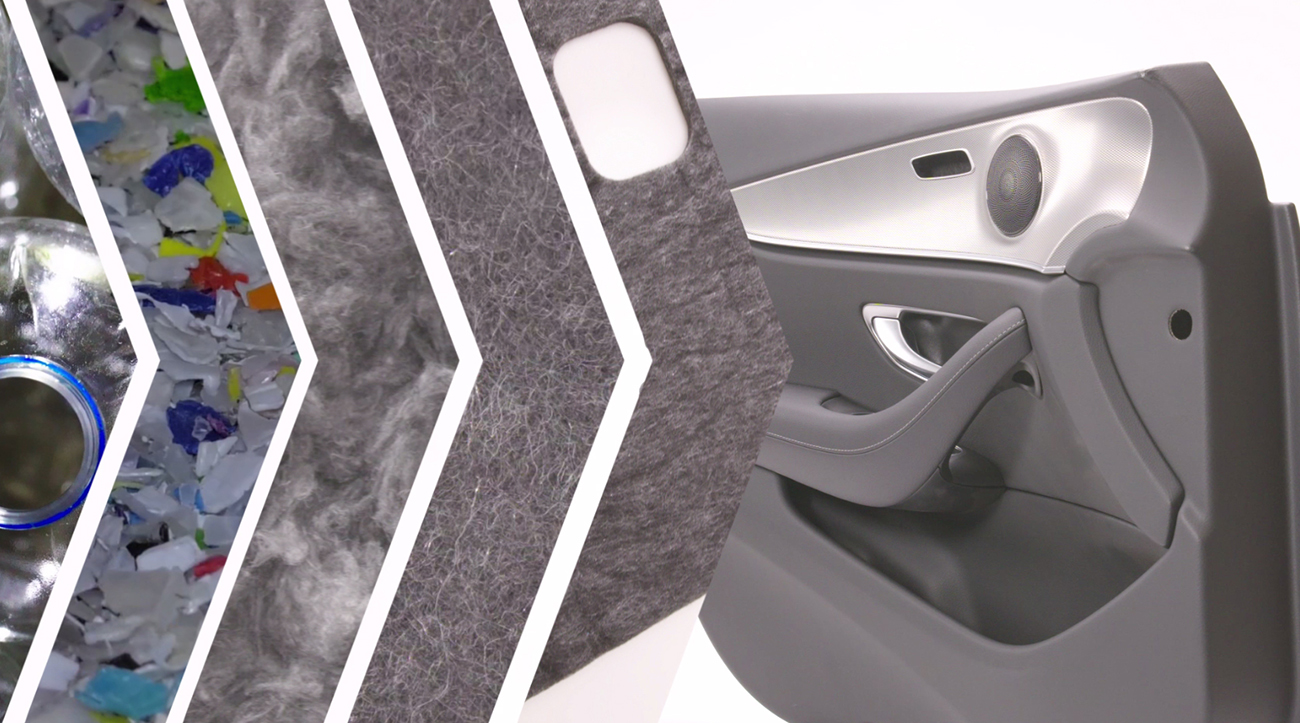

For nonwovens in technical applications, for example in the automotive industry or interior acoustics, polyester is a widely used raw material. With fibres made from bottle flakes already available, this raw material lends itself to achieving the goal of zero waste and establishing a circular economy. Demonstrating another facet of sustainability, the recycling of synthetic fibres such as polyester keeps the materials within a closed cycle as long as possible. This reduces both the use of virgin resources and carbon emissions during their processing into raw materials.

Life cycle analyses of Sandler nonwovens have shown that raw materials are the most significant factor with regard to carbon emissions, illustrating the importance of developing efficient and economically viable circularity concepts. Promoting and expanding the recycling of faulty materials and trims, identifying alternative raw materials such as biopolymers or natural fibres and investing in the development of alternative production technologies will be vital efforts on the path towards a sustainable product portfolio.

Sandler cooperates closely with customers and partners in testing and evaluating different methods of recycling. Faulty production batches, edge trims and flighting fibres are collected and transported to a partner company. The material is then re-granulated and spun into new fibres that can be used in new production processes. This method of recycling provides several advantages. First, the material does not have to be pre-sorted according to colour or material mixture and second, it only has to be a 100% single-type fibre blend.

Employing another recycling method, Sandler also collects trims from die-cut parts produced by its customers. Bales of these materials are transported to another partner company, where they are fed into the process of mechanical recycling. The fibrous materials are mechanically dissolved down to the fibre level. The resulting fibres are available as raw materials for production. Mechanical recycling is the most sustainable recycling process for fibrous nonwovens available today. It requires no cleaning of the products prior to recycling and uses little energy, generating the least amount of carbon emissions compared to other available processes. Nevertheless, it does require the nonwovens to be sorted into separate batches per fibre blend.

Cooperation and commitment are key

The key factor in successfully implementing recycling solutions for nonwovens is close cooperation between all involved partners along the value chain. Companies need to be committed to investing additional resources in the logistics of collecting and storing waste materials or trims, transporting them to the recycling facility and back to their own plants. Open-mindedness is critical. In developing new product categories on the part of manufacturers, and in using products with potentially slightly different properties on part of the customers. All companies involved are required to put in the effort to evaluate and choose the fitting sustainable solution for their respective application.

In a circular economy, a closed loop for recyclable materials can be established through cooperation along the value chain. And the actual purpose of synthetic raw materials such as polyester can be fulfilled: to be used and reused several times. This significantly reduces the utilisation of new resources and the carbon dioxide generated in raw material production.

To find out more about Sandler, visit www.sandler.de

Have your say. Tweet and follow us @WTiNcomment