Taiwanese textile industry innovators to attend Innovate 2021

By Otis Robinson

Sponsored by Taiwan Textile Federation

The Covid-19 pandemic greatly impacted the global textile & apparel industry. With the contraction of the global textile & apparel market and stringent travel restrictions, it has become nearly impossible for Taiwanese textile firms to physically attend international exhibitions.

Nevertheless, ongoing innovation in industries has led to resilient and prominent virtual exhibitions. To help Taiwan textile firms weather through this hard time, the Taiwan Textile Federation (TTF) will showcase five Taiwanese textile companies at WTiN’s Innovate 2021 virtual event. These five mills have joined the digital exhibition with their latest innovations in textiles to hand.

Acelon

Acelon Chemicals & Fiber is a specialist in synthetic yarn production. The company says it is devoted to research and development (R&D) and flexible production for POY, FDY, DTY and ATY, including functional, eco-friendly and bi-component yarns. The company’s products have multiple functions such as anti-bacterial, abrasion-resistant, flame-resistant, anti-static and thermal managing properties.

And, as sustainability becomes a priority for industry, Acelon says it has, too, made sustainability key to its made-in-Taiwan production. Its latest sustainable product, the AceEco-Bio410, a bio-nylon yarn derived from castor oil, has a lower carbon footprint compared to other types of nylon yarns, the company explains. Additionally, textiles composed of AceEco-Bio410 are lightweight, drape well, dry fast, boast a stable dyeing performance and have a comfortable feel. The bio-nylon yarn is versatile and can be used for various purposes – for example, apparel, sportswear, activewear, swimming wear, outdoor wear, underwear, lining, hosiery, umbrellas, bags, suitcases and more.

Elsewhere, its other sustainable products include AceColorEco, which is created by utilising textile waste and solution dyes.

A company representative explains: “Dope dyed colour, and using recycled materials, are the key technical elements we apply for AceColorEco. This brings the advantages of reusing waste, excellent colour fastness and saving water, energy and carbon emissions.”

The two sustainable Acelon products available can be applied to nylon and polyester, respectively.

Andersn

Andersn supplies materials for jacket insulation. The company has decades of experience in the down and feather industry and boasts certificates from the European Down and Feather Association (EDFA), Response Down Standard (RDS), Global Recycle Standard (GRS) and more. The company says its mission is to provide non-stop innovation for down function and quality improvement, to understand its partners and to provide reasonable value.

The company’s product portfolio consists of down and feathers for filling.

General Silicones

General Silicones (GS) offers technology to resolve silicone adhesion and bonding problems from the lower surface energy of silicone. Its Compo-SiL technology offers anti-slip, printable and environmentally friendly functions that are said to give the textile industry an opportunity to develop new products.

Features of the product include its silicone rubber, which “offers an innovation for the textile industry” by allowing HMA to act as an interlayer adhesive and combine with different textiles. Compo-SiL also creates custom textures on the silicone rubber layer and gives the provider “complete freedom on colours and gradient effects.”

A company representative explains: “General Silicones opens new pathways for brands and fashion designers to express themselves using silicone-rubber prints for logos and apparel design. […] As an experienced manufacturer of silicone products for customers, Compo-SiL can provide customers with products at the highest quality standard.”

Compo-SiL also meets market needs for sustainable production materials – the product has a low ecological footprint during production, use or disposal.

Makalot

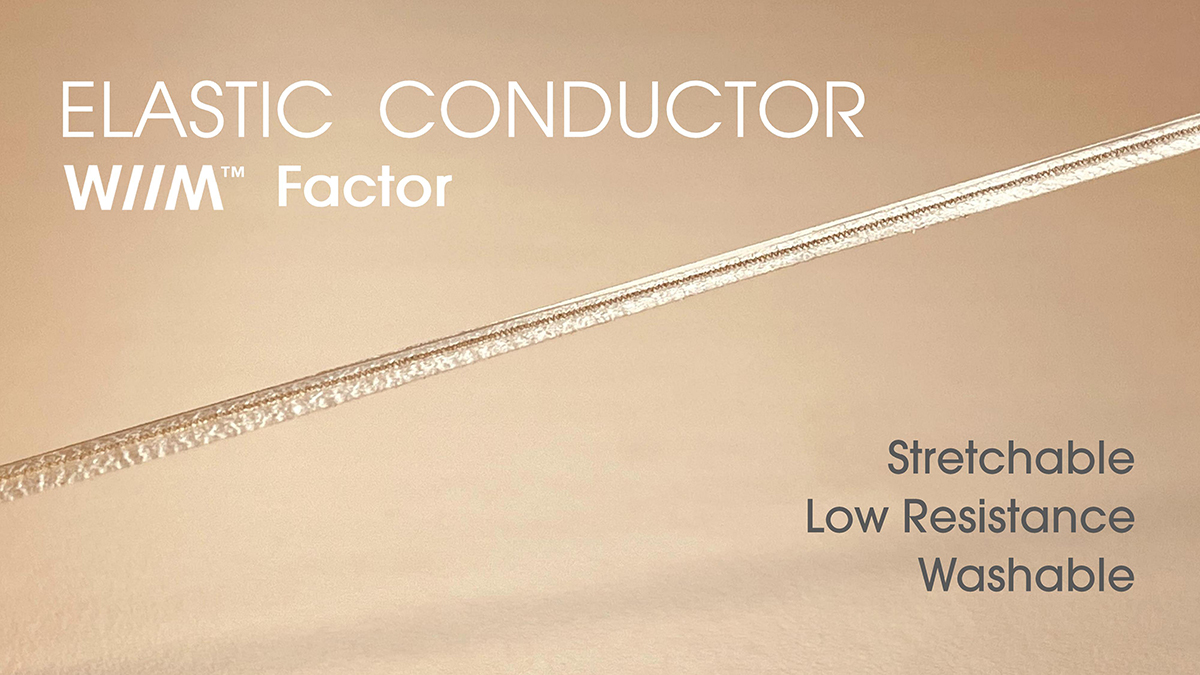

In 2021, Makalot has been creating a smart textile technology brand titled WIIM. The brand will act as a technological solution for electronic integration in textiles. The company says it will use innovative technology services, new business models, patented technologies and high-end software content to enhance the added value of textiles. Makalot hopes this will allow textiles to have multiple smart applications and enable clothing to easily connect to life through the internet.

A company representative explains: “To design smart clothing that people can wear all the time, we develop the stretchable conductor to gear up powerful technical performance and connect to the comfort of smart clothes. From bio-sensing, input/output signals to other applications, Makalot’s stretchable conductor can greatly support the future of smart clothing.”

According to Makalot, the conductor is “super thin, light, low resistant and washable,” which allows it to ‘perfectly embed’ in clothes invisibly while boasting electronic functions. It can be attached to clothing via sewing, sticking, soldering or other methods.

The company adds: “Additionally, the material can be washed and, after laundry, the stretchable conductor can still provide the same function and technology and retain the same performance.”

Xpore

Xpore, a self-professed pioneer in nanoporous membrane technology, is a provider of waterproof, breathable textile solutions, but doubly aims to provide ‘conscious adventurers’ with sustainable, comfortable alternatives to outdoor wear.

The company is also following the steps of its root company BenQ Materials by pursuing sustainability and social responsibility. Most recently, Xpore standardised and systemised its factory and working environment according to ISO 9001, a quality management system that is widely used in the electronics industry. Various protection measures have thus been implemented to ensure the safety of factory workers. Furthermore, the company adds, its products are 100% PFC-free, solvent-free, non-toxic and human friendly. Its manufacturing processes strictly follow environmental standards – for example, no air pollutants or wastewater are produced.

A company spokesperson says: “Our factory was designed to be a Green Ecological Restoration Park that is friendly for bees and endangered tree frogs. We also generate solar energy by ourselves to reduce CO2 emissions.”

Xpore has also been recognised as a bluesign system partner – bluesign is a sustainability and safety standard for the textile industry (and other similar industries) with stringent criteria.

For more information regarding the TTF or the aforementioned companies, please contact Mike Wang at swmike@textiles.org.tw. To visit the companies at WTiN’s Innovate 2021, please visit innovate.wtin.com.

Have your say. Tweet and follow us @WTiNcomment