Restrictions for sustainability within the textile & apparel industry are ever-increasing. This leads manufacturers to search for the most eco-friendly yet equally efficient technology replacements. Cara Dudgeon speaks to Alice Tonello, Tonello’s marketing and R&D director, about its new range of laser machinery, which is set to ‘transform the sector.’

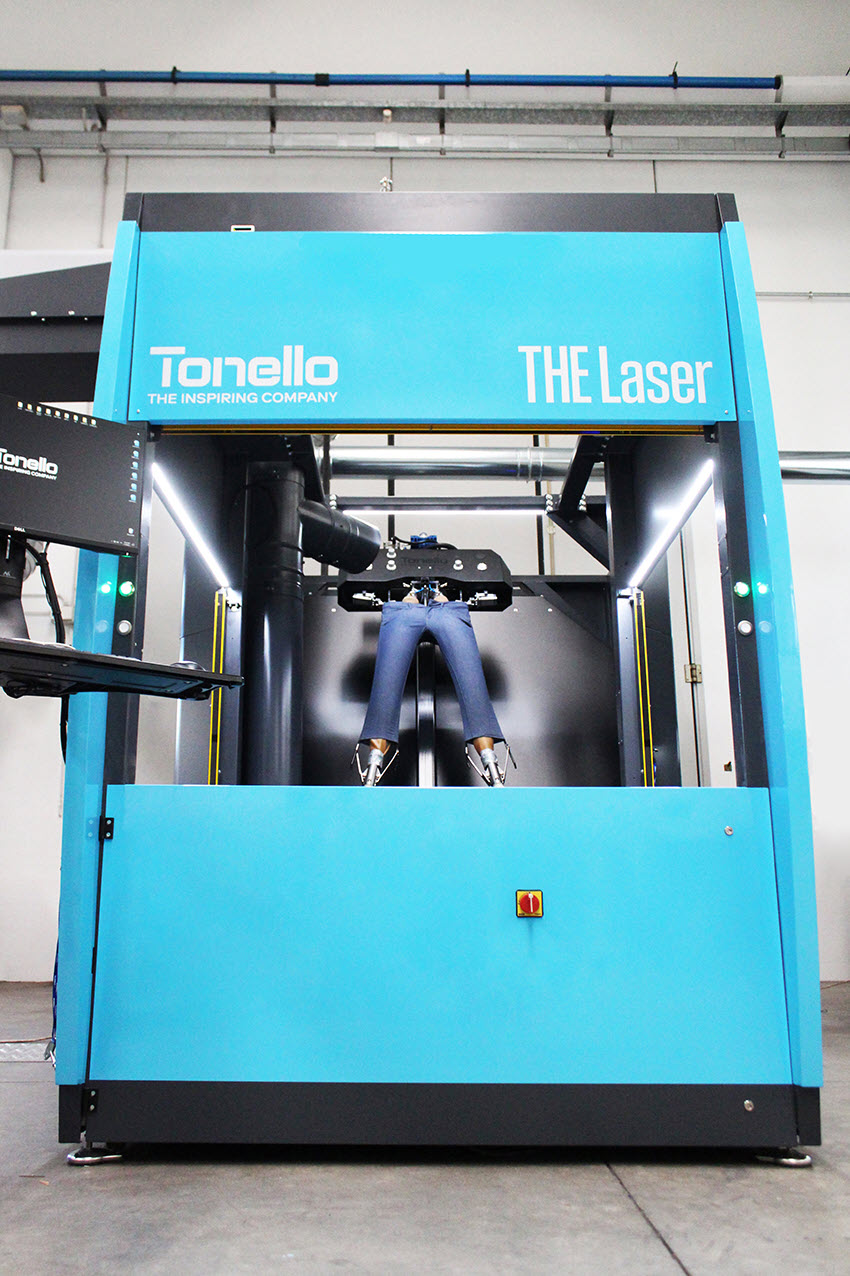

The Italian company recently launched THE Laser – an innovative line-up of lasers – which the company claims:

- Reduces overall dimensions by as much as a third

- Has the possibility of working a continuous cycle, 24 hours a day, seven days a week

- Features updated software performance

- Offers uncompromising quality

Tonello’s assortment of machines has been designed to respond to various production needs.

THE Laser Lab

The company defines this as its most compact and smart laser in the range. It’s compact as well as easy to install and maintain, according to Tonello. With its various options, the company says it can be placed either in shops or in production contexts, depending on the power and speed.

THE Laser Table

This is Tonello’s proposal for table work. Compact in size but with a large work area, the company says it is easy to use and allows you to operate either on the entire surface of the table or alternating processes in two distinctive areas. This allows for quick, flexible and varying production of the garments.

THE Laser Table & Mannequin

The company claims this machinery reinvents current table & mannequin technology. It incorporates features of the Laser Table with the new oblique mannequin. Tonello says this reduces the overall dimensions of the machine and allows for improved performance of the fully automatic and super-rapid change between the two working modes. The mannequin can also be marked at a full 360 degrees.

THE Laser Conveyor

This machine is for continuous processing on a conveyor belt or traditional fixed table. According to Tonello, it allows non-stop laser processing and garment unloading and is ideal for T-shirts and knitwear. The company also adds it is particularly flexible for laser cutting jeans.

Tonello says that for companies it might be functional to use, in combination, different laser models or in other cases only one type of machine.

Why laser?

Usually, companies choose laser finishing to substitute manual abrasion – a process that includes sanding each jean by hand. Not only does it become safer when opting for laser, but it is also reproducible, accurate and faster.

According to Alice Tonello (A Tonello), the company’s marketing and R&D director, these qualities can also be attributed to the new range. She says: “The ability to switch from working on the fixed table to working on the mannequin immediately (table & mannequin model).

“In addition, the use of a special mannequin that allows for 360-degree working, so as to ensure an extremely natural look on the entirety of the jeans.”

The company is also aware of production space and due to an engineering study was able to compact the sizes of its new range of machines. It has done this by repositioning of some elements of the technology.

Software

Along with its four machines, the company has launched two new software technologies: Crea and B.O.P. (Be On Point).

Tonello’s crea software is standard on all its laser machines and is what allows each of the machines to be driven. It can be used independently by any designer who simply knows the basics of graphic design, according to the company.

A Tonello says: “Crea is a complete, self-sufficient graphic software serving the creativity of designers with high levels of customisation parameters such as powers, intensities, resolution and more.”

Crea’s creative tools allow manufacturers to edit a design directly on the machine, says the company. It can then to go straight into production without having to be transferred to other external design and editing software.

The software incorporates a library of images that contains many files – whiskers, abrasions and graphics – that allow for endless combinations tailored to each creative project. The images are usable at will and can be edited as needed without hassle and in total autonomy, even with external software, according to Tonello.

In addition, the many filters and modes allow you to create an extremely natural-looking garment. A Tonello gives the example of the scraping filter, which she says, “gives the design an authentic hand-scratched effect with just one click.”

The B.O.P. (Be On Point) system for automatic one touch garment positioning allows the garment to be placed on the work table without particular accuracy or precision on the part of the operator, according to the company.

A Tonello says: “In short, B.O.P. instantly recognises and reconstructs contours, shapes and volumes of the garment, regardless of its position. It also enables the perfect and repeatable application of designs made with Crea, for which B.O.P. is the ideal complement.”

B.O.P. can only be installed on the Table and Table & Mannequin models and is suitable for minimising errors and possible production waste, increasing the speed and ease of processing.

The garments on the table can be placed differently each time at different angles and heights, but the design will always be placed by the system exactly in the position chosen by the operator during the creation of the initial design.

B.O.P. can be managed directly from the Crea software at the touch of a button.

Laser finishing trends

In recent years, the industry has seen a decrease in manual applications due to the increase in available technology.

A Tonello says: “Laser makes it possible to create a natural effect and to expand the horizon of finishes that can be done, such as graphics, logos and special effects; details that manually would be impossible to achieve.”

She adds that finishing application on garment dyeing is an interesting trend that she expects to see more of in the next few years.

Have your say. Tweet and follow us @WTiNcomment