Dr John Brockgreitens, research and development director at Claros Technologies, talks to Madelaine Thomas about its proprietary technology that completely destroys PFAS from textile wastewater and materials.

The dyeing & finishing industry is the dirtiest sector within the textile & apparel industry – which in itself is one of the more pollutive industries globally.

Claros Technologies, a US-based company that was incubated at the University of Minnesota, is working to clean up the industry by capturing and destroying per- and polyfluoroalkyl substances (PFAS) in textile wastewater. This is a huge step forward for the industry, particularly as companies in manufacturing nations are hit by new regulations that reduce the amount of textile effluent and wastewater that companies can create and dispose of.

This has most notably been seen in China, the powerhouse of the dyeing and finishing world, where countless dyehouses have been closed as they have failed to meet wastewater creation and energy and chemical consumption targets.

The problem

Per-and polyfluoroalkyl substances (PFAS) are a class of extremely stable, water- and oil-resisting compounds used in a wide variety of industries and consumer products. Found in drinking water of an estimated 200 million Americans, PFAS pose substantial risk to public and environmental health, having been associated with immunosuppression, reproductive issues and a variety of cancers.

This risk is compounded by the inability of natural processes to break PFAS down due to their extremely strong carbon-fluorine (C-F) bonds, earning PFAS the title of “forever chemicals,” says Claros Technologies.

While there are wastewater treatment solutions in the market now, currently PFAS waste, including spent filter materials, are sent to landfills or are incinerated, according to Claros Technologies. Research has shown these disposal methods do not break the carbon-fluorine bonds, resulting in reemissions of PFAS into air, water and land.

Consequently, several US states and countries, such as Japan, are seeking to ban incineration and landfill disposal of PFAS waste. Claros’ PFAS remediation ecosystem represents a significant step towards a comprehensive life cycle approach to waste management backed by detailed analytics and sound science, the company says.

“Our approach is to concentrate PFAS from millions of gallons of wastewater into a few gallons of PFAS concentrate that can be cost-effectively and permanently destroyed in a traceable fashion,” says Dr Abdennour Abbas, Claros founder and CTO.” It works on a variety of industry wastewater and even on firefighting foam.

“Changing the way we treat our chemical waste by adopting a closed-loop system will not only reduce risks for the public and the environment, but also eliminate latent and future liabilities for manufacturers and waste disposal companies.”

Technology

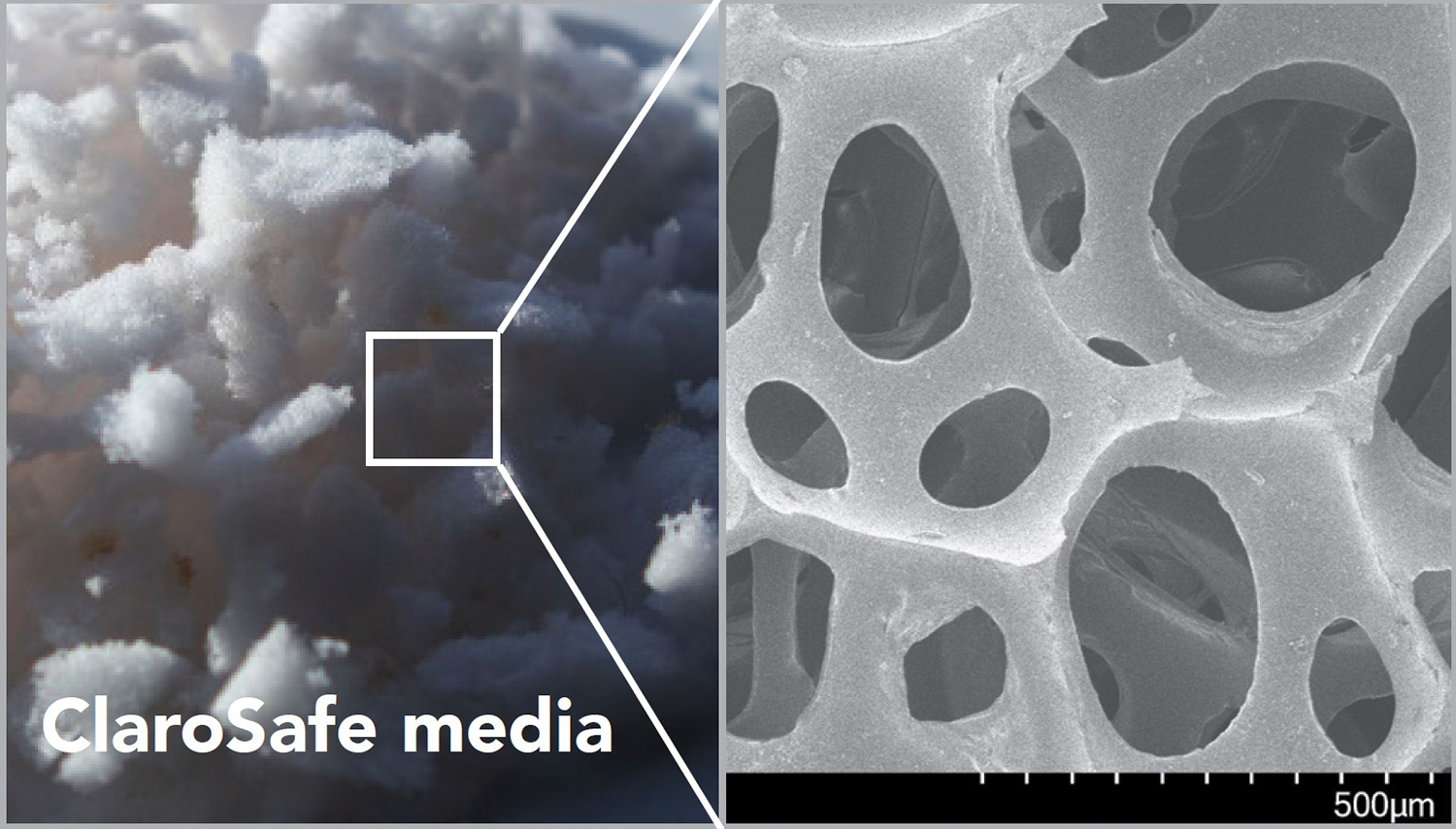

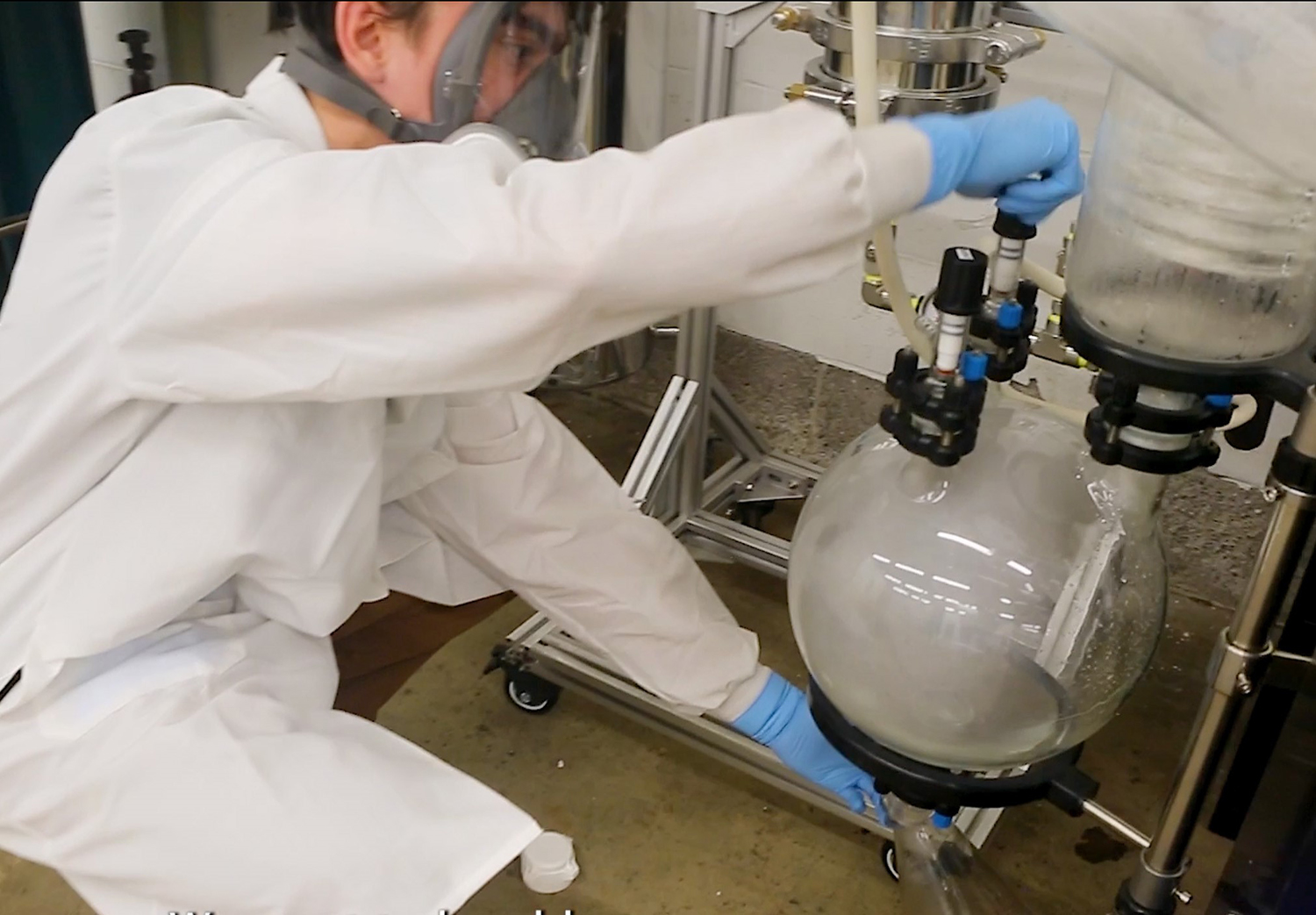

Claros Technologies has been working on its proprietary technology since 2018. Dr John Brockgreitens, research and development director at the company explains: “We are able to actively grow, for lack of a better word, chemical functionality on to support materials.”

These support materials can be anything from a porous material to a soft material, whether it is a textile or a water filtration membrane. Brockgreitens says that whatever the substrate, “we can put our technology on it and make it do something else. For example, in our textiles offering, we were able to put Zinc materials on to cotton and polyester, both natural and synthetic fibres and make those antimicrobial and antiviral.”

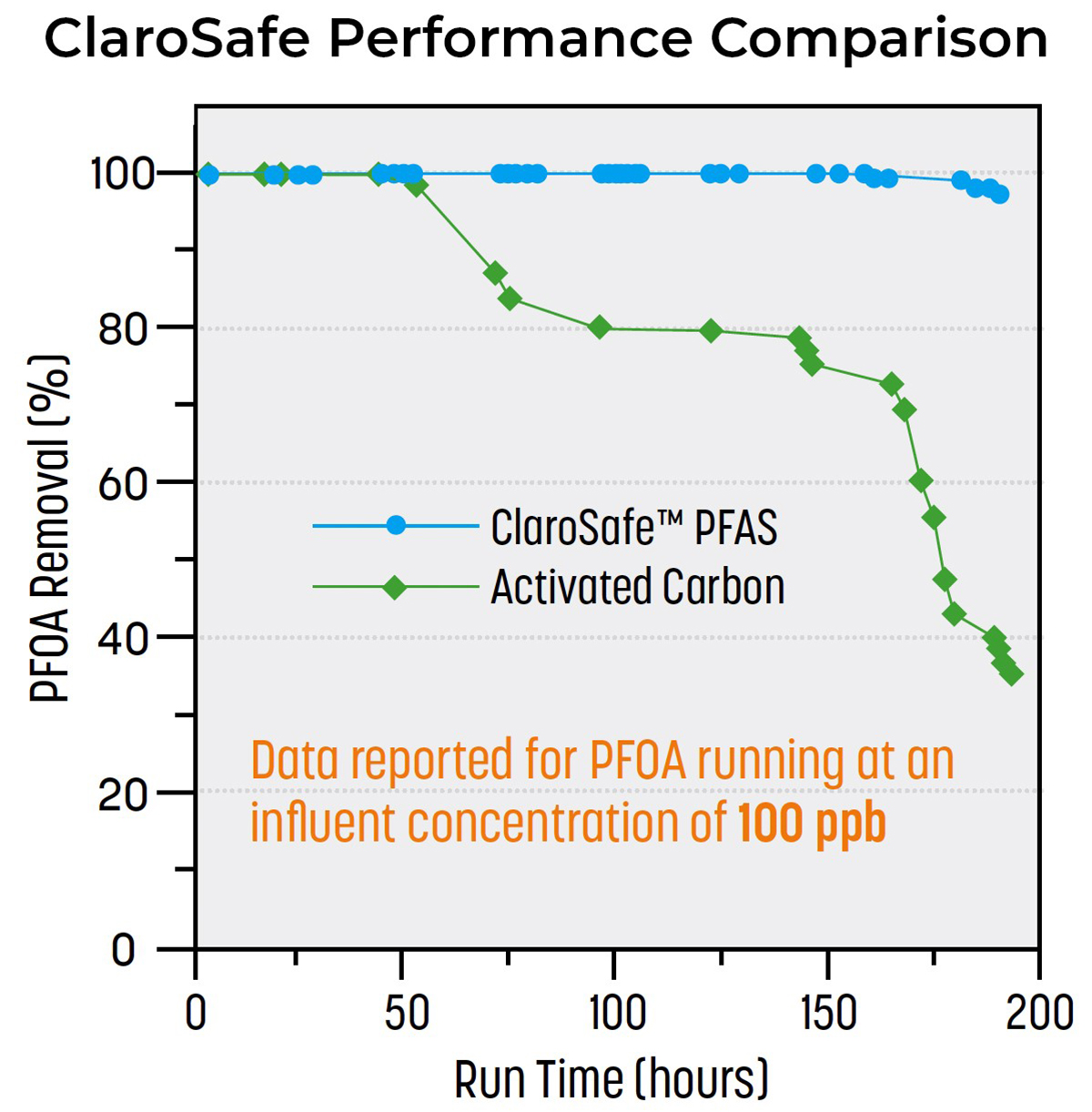

He adds: “In the world of environmental treatment, we're able to do the same thing. We grow active materials onto water filter membranes and that allows us to tune the chemistry of those materials to capture pollutants.”

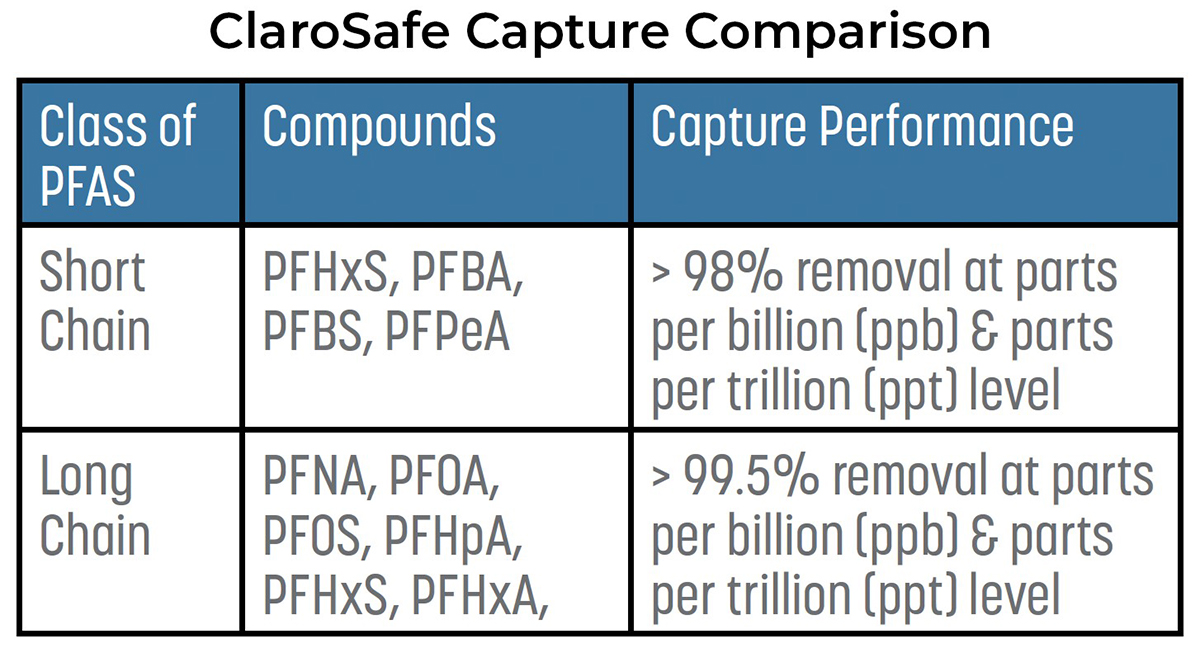

For example, the company has a material that it uses to capture PFAS from water. Brockgreitens says: “The material looks very similar to a water filtration membrane that you would have under your sink or in a commercial or industrial setting. But our chemistry allows it to more favourably bind and remove PFAS from water.”

Everything that Claros Technologies develops is based on that same patented treatment process that allows the company to put active ingredients on to typically fibrous materials.

The idea for this patented technology was born when Brockgreitens, co-inventor of the technology, was a student at the University of Minnesota in the US. He used selenium material to capture mercury from a product. Brockgreitens says he and the rest of the team went into the lab knowing they wanted to use selenium to capture mercury as it’s good at removing mercury from water.

However, he notes, “when you utilise a small material [nanoparticles], it's very difficult to get it back out of water.” The methodology the team used bound the mercury to the selenium, bringing it out of the water. With the mercury now bound to the selenium, the team thought they could then put this into something else.

He says: “That way, we can take advantage of the fact that it binds nicely to Mercury, but we can put it into something that's a little bit easier to handle. What we developed is this process to grow this material into textiles.” The research team first used a sponge.

Brockgreitens continues: “We took a sponge and added the selenium material to it. We then grew that functionality throughout the sponge, and we now have a Mercury capturing sponge.”

The liquid solution applied to the substrate is a proprietary chemistry. Brockgreitens says: “It’s similar to dyeing in textile operations. We dip the material choice into that chemistry and then everything we do is driven by heat. We recreate very small salt crystals, essentially, to put that functionality throughout that material.”

And this process, importantly, uses little energy as it has a “very low” temperature synthesis process, according to Brockgreitens. However, once these harmful chemicals are captured, such as the PFAS, they must be destroyed. PFAS are known as forever chemicals, so destroying them isn’t easy.

“PFAs are made of carbon fluorine bonds, that's the strongest bond in organic chemistry,” says Brockgreitens. He adds: “Once we deploy our media into a water system and we've captured the PFAS onto that media, we take it back [to the company’s lab] and extract it from the material.”

The company works differently to others that claim to destroy PFAS from the environment. Brockgreitens notes that Claros’ technology complete breaks down the carbon fluorine bond in PFAS, whereas other companies just break the bonds down in to smaller compounds. They are therefore not totally destroyed and are still travelling in the environment.

“What Claros has been able to demonstrate is that we're actually showing that we have broken the carbon fluorine bond, and that the PFAS have been converted into their constituent elements, namely carbon and fluorine,” says Brockgreitens. He calls this complete destruction as it is 100% eradicated from the environment.

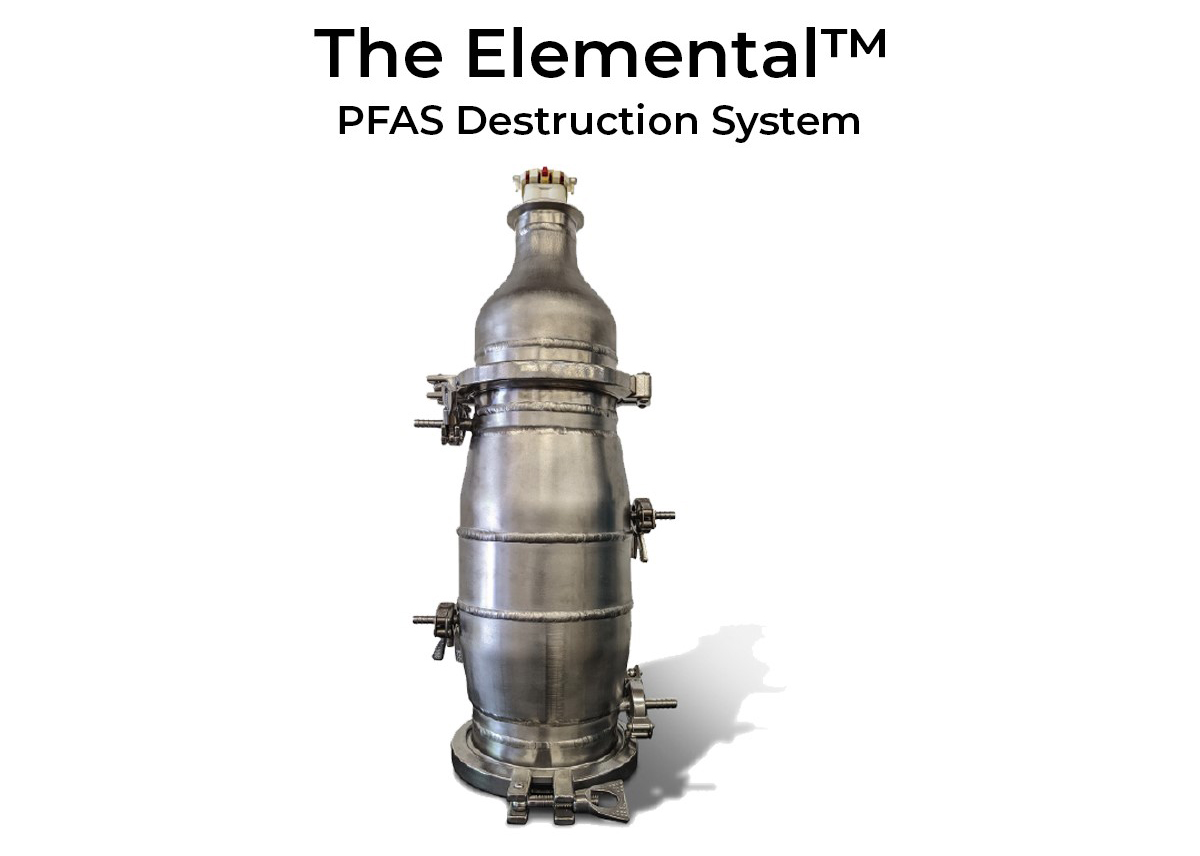

For the destruction, the company can export the captured PFAS to its treatment facility and destroy the PFAS for a customer or, depending on their facilities, Claros can work with customers to develop their own treatment system so they can carry out destruction on site.

Claros has recently partnered with a Japanese company to help it establish capture, concentration and destruction capabilities in its facilities in Japan. “So, while we are trying to expand our footprint here in the US, we are also trying to expand our footprint into Asia,” says Brockgreitens.

Textiles

It’s not just the textile industry that Claros’ technology is relevant for, but many other verticals that use harsh chemicals. However, the company had its sights set on helping the textile market from early on.

At the beginning of the company’s inception at the University of Minnesota, Brockgreitens and the rest of the team were given two grants. One was from the US Environmental Protection Agency, focusing on the removal of PFAS from water and the second was from the US Army, looking at functional army uniforms.

Brockgreitens explains: “The US Army wanted a treatment process that could put multiple value-added functionalities into their uniforms that included antimicrobial, antiviral, UV protective and anti-odour applications.”

The Claros team completed this project in January 2020, just before Covid-19 became global pandemic. Brockgreitens continues: “When Covid-19 came around, we took that same technology that we had demonstrated to be antibacterial and antiviral, and we applied it against coronaviruses.” He says this was a big driver for the company in its development into the textile space.

Challenges

While the company’s innovation clearly provides much opportunity, it is not without challenges. The organisation’s motto is to “solve problems without making new ones”. Thus, with all the PFAS captured and in need of destroying, Claros has had to scale up its destruction technologies. However, not to the levels that one may think.

Brockgreitens says: “There’s a big push to try to scale up destruction technologies but our approach is we’re just trying to scale down the PFAS problem. We are taking PFAS from hundreds of thousands of gallons of water and capturing it and scaling it down to smaller sizes, which means there isn’t the need to scale up the destruction technology [to the same degree].”

He continues: “There's an inflection point where there's a cross: as we scale down the PFAS problem and scale up the destruction, there's a point in the middle where we'd like to meet.”

Another challenge for Claros Technologies relates to the nature of water. Brockgreitens notes that one of the biggest obstacles the company faces is that no water is the same – and this makes treatment difficult. The company has had to look at how its chemicals and media work to capture PFAS from a variety of different water streams. It dedicated a lot of energy and resources to build its own in-house testing facilities.

Future

Scaling its technology, Claros Technologies has entered a strategic partnership with Kureha America, a wholly owned subsidiary of Kureha Corporation Japan, to scale up its state-of-the-art technology that is capable of capturing, concentrating, and destroying “forever chemicals” from wastewater.

Naomitsu Nishihata, president of Kureha America, says: “As a chemical company, Kureha has a responsibility for mitigating the environmental impact of PFAS. We seek to be socially responsible, accelerate innovation, and expand our business portfolio and Claros’ comprehensive PFAS solution helps us meet each of those goals.”

Despite the efforts of the industry, Brockgreitens does not think we will reach the point where PFAS have been totally eradicated in the coming decades. He says: “They are something that will be with us for a while, whether or not they're phased out industrially. We will still have instances of PFAS in water, in the soil. They’re called “forever chemicals” for a reason – they don't go away depending on whenever they're used, they will continue to cycle through the environment. So, there will always be a need to remove them somewhere, in my mind.”

Have your say. Join the conversation and follow us on LinkedIn