Sponsored by JK GROUP SpA

Sustainability has and always will be of the upmost importance. However, in recent years the entire manufacturing industry has begun to mobilise like never before when it comes to manufacturing in a cleaner, greener way. This mobilisation is driven by consumers, regulators and governments.

JK Group, part of the Dover Group, however, began manufacturing water-based digital textile printing inks 20 years ago. Davide Dragoni, JK Group product development manager says: “Sustainability is a choice only possible with a daily hard commitment that requires constant investments over time. From its birth, JK Group chose to design eco-friendly, water-based inks and abandoned the production of the international patented eco-solvent-based ink formulation.”

Many companies are turning to sustainable initiatives. However, they have been meeting accusations of greenwashing. Dragoni says: “It is easy to confuse sustainability with greenwashing. The consumers' awareness of sustainability has grown exponentially in the past few years. This has consequently pushed the entire textile printing industry to pay more and more attention to this hot topic.”

Rather than greenwashing, though, Dragoni notes that 25 years of commitment and investments are a matter of fact. The company adds: “Once you become aware of this, it is easy to distinguish sustainable commitments from greenwashing. Sustainability relies on full transparency, traceability and auditability of products and production processes; greenwashing relies on hazy claims that don’t find confirmation in practice.”

Dragoni explains that, over the years, JK Group has built:

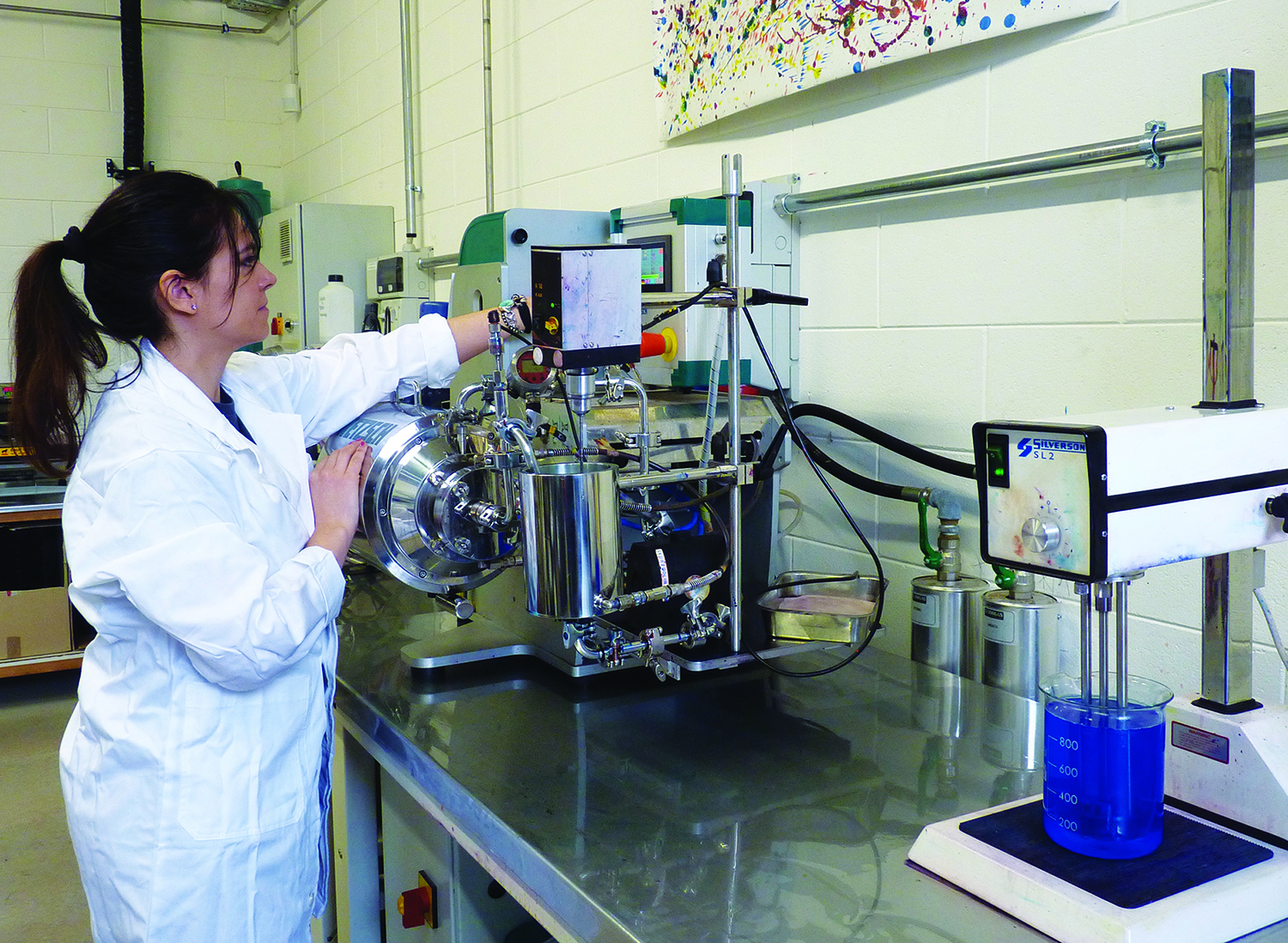

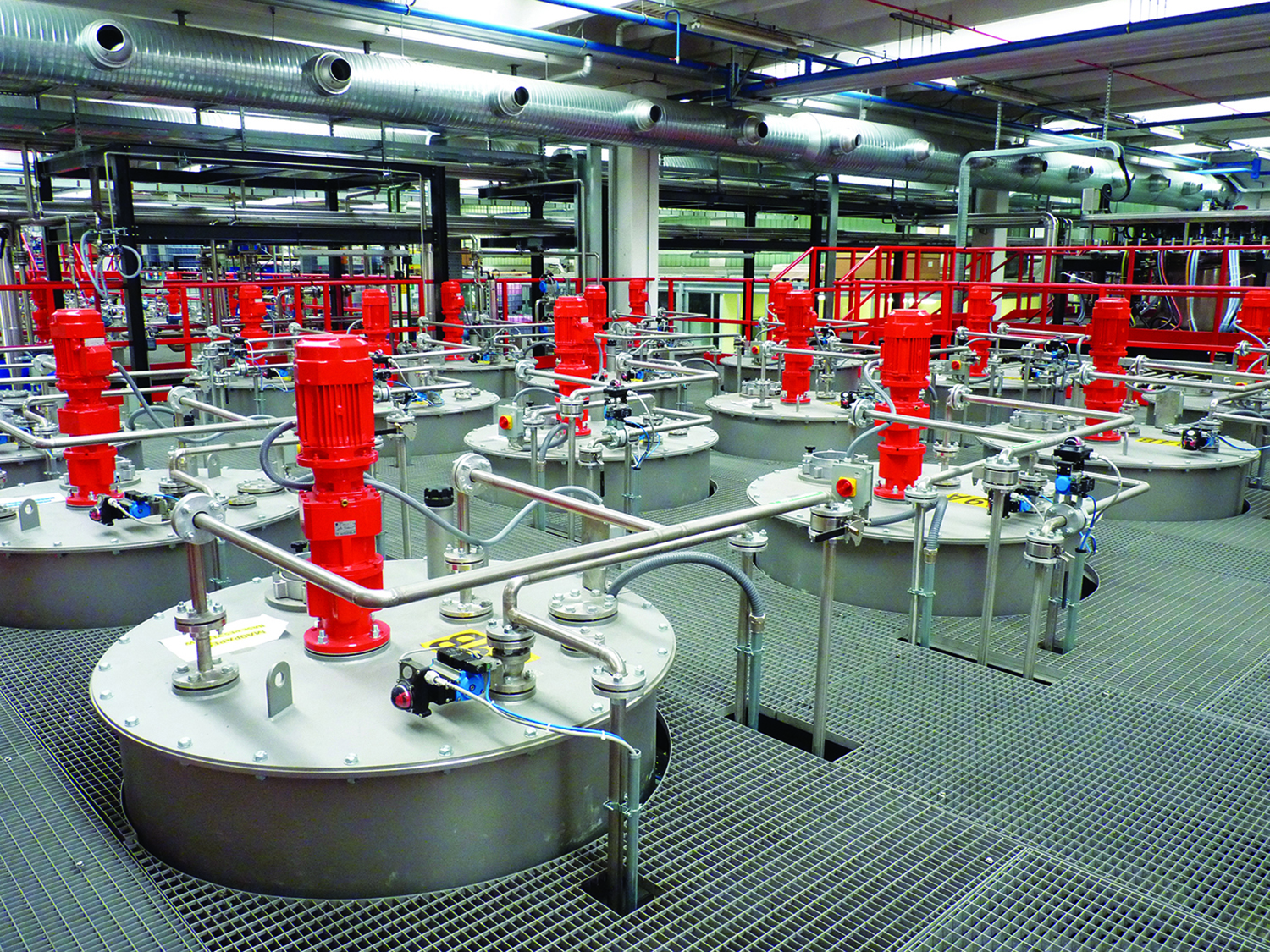

- A forefront plant in terms of both automation and structural design. The facility is designed to limit the waste both in terms of space and raw material. The company has set up an advanced process monitoring system to ensure reliability. It has five checkpoints during production for a total of 40 different controls to assure reliability and conformity to the compliance and technical standards.

- A close collaboration between the R&D team and a team of experts in Chemical Management Risk (the Compliance Team) has been made possible by the company. Both teams work side by side, selecting the chemical substances to be used in the formulations and updating the existing ones so that they meet the strict global textile requirements through constant monitoring and regular updates. At JK, sustainability starts from the design and research for raw materials involved in the formulas, opening our production plant for a third-party inspection like the ones operated by GOTS and OekoTex for Eco Passport certification.

- JK decided to certify inks and inhouse processes by supporting printers and the fashion industry in reducing their environmental impact, ensuring the traceability of printing process. JK’s range complies with ZDHC L3 and Eco Passport (Eco Passport certified the highest level of ZDHC MRSL conformance – Level 3 – within the ZDHC Gateway), as well as restricted substance list by the most known sports brands. The company’s inks are properly classified under GHS standards due to a devoted team mapping substances, monitoring global regulatory changes, anticipating them and mitigating chemical risk. Thus, ensuring the best guidelines for R&D for the current product update and any new products.

- The packaging chosen for JK’s new ink process line is bag-in-box (BIB). This is a project born in JK’s production site dedicated to reactive inks. It consists in a flexible PE or multilayer plastic bag, placed inside cardboard that assures lots of advantages, according to Dragoni. The company says BIB offers a significant reduction (around 80%) in the use of plastic, compared to the traditional HDPE tanks of similar capacity. Also, BIB components can be separated into plastic and cardboard, allowing an easy recycling of the cardboard. Likewise, they can be folded offering storage space optimisation. Dragoni says: “The combination contributes to achieving a significant reduction of CO2 emissions for our customers.”

- JK Group is rethinking its logistic presence and organisation to reduce its water consumption. Dragoni says: “Thanks to the synergies with Markem-Imaje networks, we exploit local sites, rationalising and reducing the movement of goods, by acting on our global emissions. This will allow better management of shipments and upper service level for the customers.”

- The company developed its first pigment printing solution back in 2015 and now has its third generation inks. Pigment printing uses less water and energy consumption. Printing with pigment inks is an easy and waterless process, suitable for a wide range of fibres, Dragoni says. The pigment printing process allows for a more sustainable production chain, ensuring cost-effective printing outputs. Pigment inks, therefore, translate to smaller investment costs. Dragoni explains: “The use of just one ink for natural, synthetic and fibre blends allows printers to promptly react to market changes in a time of uncertainty for the global textile market.”

- JK Group is aware that sustainability is also about people. Organisations cannot be sustainable without protecting the safety, health and welfare of their most vital resource: workers, Dragoni says. He adds: “Integrating health and safety into these innovative and proactive strategies provides a transformative opportunity to achieve a truly sustainable organisation.” In sum, embracing health and safety as a cornerstone of sustainability is good for workers and good for business. Dragoni continues: “A stronger commitment to health and safety can benefit workers by decreasing the number of illnesses, injuries and fatalities; increasing engagement and satisfaction and enabling them to be productive participants in the organisation and its communities.”

Have your say. Join the conversation and follow us on LinkedIn