-

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

In celebration of International Women’s Day, WTiN has pulled together three scaling innovations that have women at the helm: from plant-based to carbon eating and knitted wearables.

The first National Woman’s Day, a precursor to International Women’s Day, took place in New York City (US) in 1909 and ties in with the textile industry. The day was created to honour the garment workers’ strikes the year before, in which women protested about their working conditions. Thousands of women marched through the city, garnering attention from around the world.

The movement grew internationally and German campaigner and socialist Clara Zetkin took the idea to turn the day into an international movement to advocate universal suffrage, establishing the International Conference of Working Women in 1910. Now, it is a global day celebrating the social, economic, cultural and political achievements of women.

WTiN covers a multitude of areas within the textile industry, and we have pulled together three recent scaling companies that have women at the forefront of innovation.

Biophilica: plant-based leather

Founder: Mira Nameth

Founded: 2019

Location: London, UK

Commercial readiness: Scaling

One of many tackling the alternative leathers challenge, Biophilica’s unique value proposition revolves around the use of lignocellulose feedstock – dry plant matter, such as leaves, twigs and bark. The materials are gathered from an array of sources, including urban parks, like those in proximity to its London headquarters, as well as forestry and agricultural settings.

Once collected and processed, the feedstock is combined with a bio-based binder to form a reportedly 100% bio-based textile sheet material, dubbed Treekind. Treekind is claimed recyclable and biodegradable, while ISO tests and analysis report no detectable trace of formaldehyde, volatile organic compounds (VOCs) nor pesticides. Its composition, involving bio-based ingredients and finished with natural dyes, negates petrochemical ingredients and synthetics dyes.

Since our coverage in early 2022, the innovator has participated in several collaborations and competitions, leveraging opportunities to further develop and scale.

These ventures include partnering with fashion brand Hype and the UK-based Institute of Engineering and Technology (IET) for its #BackPackToTheFuture competition. The collaboration included the development of a promotional Hype backpack consisted of Treekind – the first backpack to utilise the material – which displayed in Hype’s flagship store in London.

Biophilica has also recently engaged with the Blue City Circular Factory Program. Based in Rotterdam (Netherlands) – a city with ambitions to become entirely circular by 2050 – Blue City is an incubator for companies with circular potential. The Circular Factory Program intends to support selected start-ups in setting up demonstration plants for their respective products, providing access to possible financiers, facilitators and experts.

Biophilica featured in WTiN’s 2022 Innovation Outlook: Fibres & Yarns Special Edition, alongside alternative leather peers NFW and Bucha Bio. Discover more about these innovations here.

Rubi Labs: textiles from carbon emissions

CEO/Founder: Neeka Mashouf and Leila Mashouf

Founded: 2020

Location: San Leandro, California

Commercial Readiness: Scaling

Rubi Laboratories uses biochemical processes powered by enzymes at an industrial scale to “eat” carbon emissions and make carbon-negative, resource-neutral textiles. With twin sisters Neeka and Leila Mashouf at the helm, the start-up has found a way to convert carbon emissions into naturally biodegradable textiles. The sisters are nieces of the founder of the Bebe fashion brand.

Rubi’s process involves taking carbon emitted by manufacturing plants and converting it into viscose, also known as rayon. By utilising enzymes as the catalyst, Rubi claims it can turn 100% of CO2 input into the reactors into an end product, all with zero waste.

The company partnered with brands Reformation, Ganni, Nuuly, H&M and Patagonia to decarbonise the fashion industry just this month, as covered by WTiN. Rubi said it wants to usher in a new era of symbiotic manufacturing, working with global fashion brand pilots, additional series seed funding led by Talis Capital and a growing team of top scientists.

Rubi said: “[We] have the capital, talent and technology to rapidly scale [our] production process, push innovation through the apparel supply chain and deliver limited collections of planet-positive apparel.”

Kathleen Talbot, chief sustainability officer and vice president of operations at Reformation, said: “Rubi is turning fashion’s supply chain on its head, transforming a wasteful and resource-intensive process into a net positive for the planet.”

Within the last year, Rubi has captured the interest of the scientific community, investors and supply chain experts. The company has received a US$250,000 grant from the National Science Foundation, raised US$4.25m in pre-seed funding, won the H&M Foundation’s Global Change Award and was included as a changemaker by Fashion for Good.

Louisiana State University: smart knitted wearables

Researcher: Sibei Xia

Location: Louisiana State University, US

Commercial readiness: Emerging

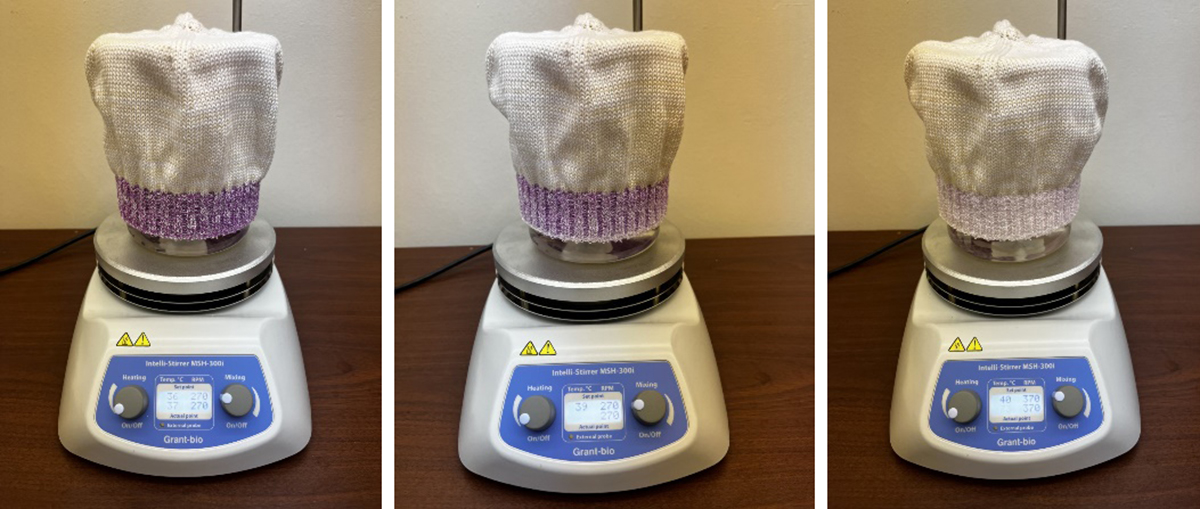

Sibei Xia, assistant professor in the department of textiles, apparel design and merchandising at Louisiana State University (LSU) has developed a hat that uses thermochromic yarn to monitor the temperature of an infant.

The hat is split into two sections: a white upper and a purple band. The white section is 100% natural cotton whilst the purple section is thermochromic-coated polyester. According to Xia, the thermochromic yarn’s molecular alignment can change colour when the temperature shifts – it is this which notifies parents of an infant’s wellbeing.

She said: “When the temperature is lower, the molecules arrange in one way and this changes when the temperature increases. It is this change in alignment that makes light waves reflect differently and, hence, change colour. When the yarn cools down it returns to its original colour, meaning it can be reused.”

The researchers use a Shima Seiki flatbed knitting machine for their process and opted for knitting over other processes such as wovens as they believe there are multiple benefits to knitting: most importantly its natural stretchiness as this allows the garment to be close to the body for the detection.

So far, the researchers have only tested the garment using a beaker of water to stimulate the temperature change. But they are putting proposals together to get baby thermo-mannequins that would allow them to test the product as it would function on a baby with moisture and thermal simulations.

The main challenge the researchers are facing though is FDA approval – something they don’t currently have. However, Xia believes the product is likely to receive approval given that this type of technology is used in various other baby products, such as beakers.

The researchers are currently sending out surveys to parents and guardians with infants of different ages to get feedback on any potential areas of improvement, but Xia believes the innovation can easily be scaled when viewed from a manufacturing process.

She said: “There is no limitation regarding the technology as the yarn works with the machines. Once we have figured out the configurations of the yarn, all we need to do is create at a mass scale and it can go on the market.”

Other female innovators

Want to discover more? We’ve compiled a roundup of other female innovators featured across WTiN.com, spanning bio-based fibres, microplastic pollution and seaweed-derived pigments. Take a look below:

Have your say. Tweet and follow us @WTiNcomment