Sponsored by Brother

The words flexibility and versatility have been bandied around the textile printing industry for some time, and they haven’t gone unnoticed at Brother. The industrial garment printing expert has branched out into the latex wide-format market with the launch of its WF1-L640 machine at FESPA 2023 in Munich.

The printer is compatible with a wide range of applications such as interior decorations, banners, drawings, window graphics, storefront signage, trade show graphics, vehicle wraps and outdoor advertising. The WF1-L640 can also print onto coated and uncoated media that’s up to 1,615 mm wide.

Folker Stachetzki, Brother’s head of marketing, says: “During development, the focus was on potential customer needs. We have years of experience manufacturing industrial garment printers and, because we develop and manufacture our own print heads and inks, entering the latex wide-format sector was a logical next step for us.”

Consumables

Brother has developed an eco-friendly, weather-resistant, water-based latex ink in conjunction with the WF1-L640 printer. The formula has been awarded GREENGUARD Gold certification, which includes health-related criteria to ensure products are suitable for sensitive indoor environments. Stachetzki says the ink is even safe to employ in restaurants and educational institutions.

He also reminds us that Brother’s name is synonymous with “reliability and good service” and that these traits have been carried forward to its latest printer and ink combination.

The new water-based latex ink has an expanded colour gamut, courtesy of the digital CMYK colour model. “The colours are expressive and have a high intensity and saturation,” continues Stachetzki. “We are preparing ICC profiles for the WF1-L640 that can be drawn upon to achieve perfect results.”

The equipment manufacturer also says its latex printer offering is equipped with new piezo print heads. They are arranged diagonally and provide an efficient printing process: the optimiser is applied first, followed by the CMYK inks, says Stachetzki. This generates a higher quality print with a maximum resolution of 1,200 dpi.

Experts believe piezo print heads are easy to control and therefore improve print quality. “Due to a variable drop size, which can go as low as five picolitres, Brother’s new heads offer sharper and grain-free results with smoother tonal transitions,” Stachetzki says.

They also have a long service life, and the equipment developer says users of both the inks and the print heads will benefit from a high colour depth. And there is an economic benefit too, which is critical for users in the current climate. He adds: “Because our self-developed print heads are designed for longevity, running costs are drastically reduced.”

Usability

To meet the needs of the modern-day consumer, printer service providers must maximise uptime and productivity. To do that, they require machinery that is user-friendly.

Brother recognised this when developing the WF1-L640: it is a high-production machine equipped with a seven-inch touch screen with a menu installed. It also comes with professional production Raster Imaging Processor (RIP) software, which is key to optimise colour management and customer satisfaction.

Garment printing

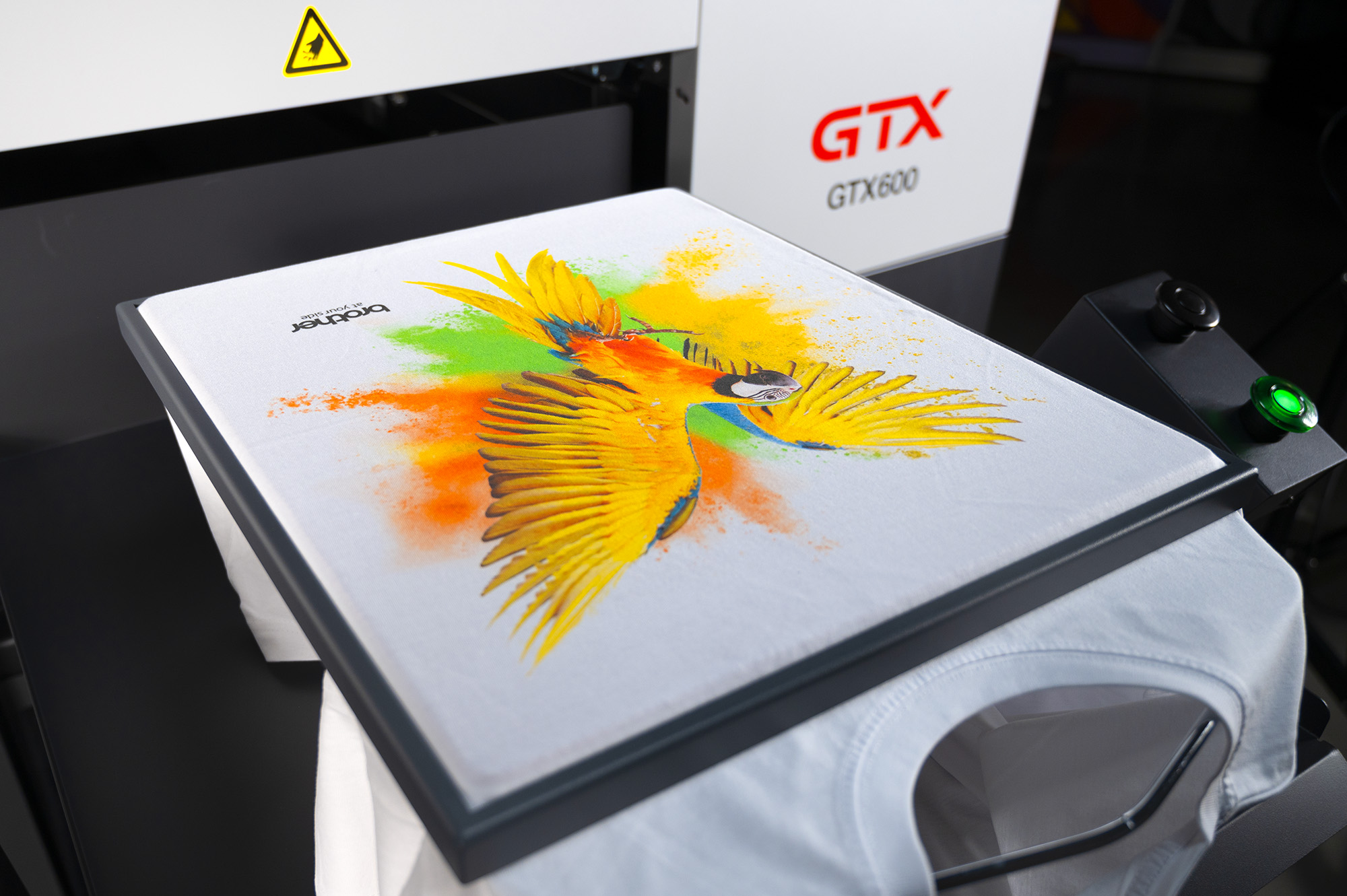

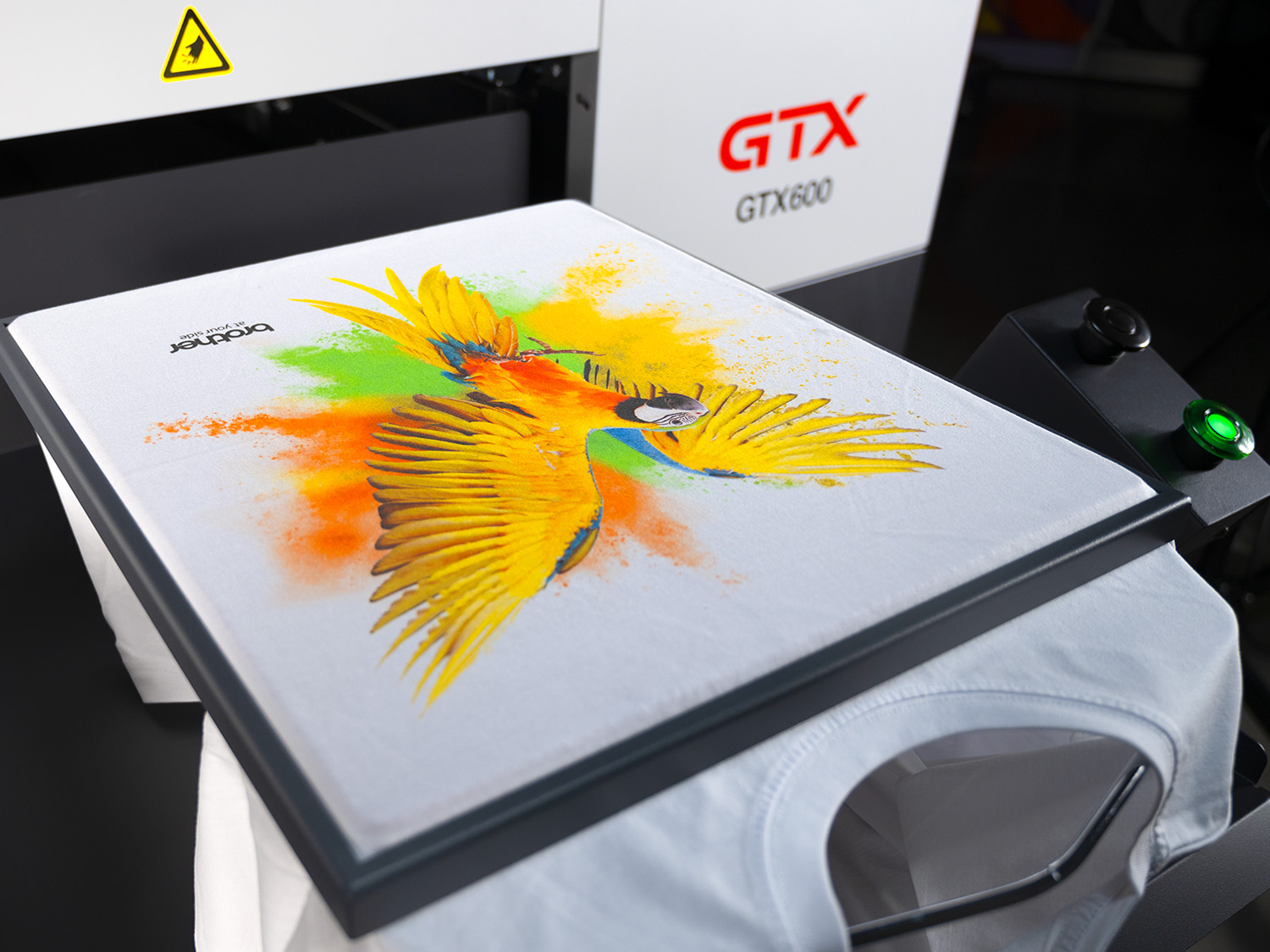

However, Brother has not abandoned its roots. While expanding into the wide-format latex printer market at FESPA, the company is also growing its GTX series with the introduction of its GTX600 Extra Colors.

The industrial direct-to-garment (DTG) printer has been further refined to include orange and green inks for more vibrancy, Stachetzki says. The upgraded model also comes with two extra tanks and two more print heads. “The outcome is a wider colour spectrum and a realisation of the best possible colour dynamics,” he continues.

The GTX600 has proved popular since its launch in 2021. Brother has capitalised on growing demand for DTG printing around the world as consumers increasingly demand personalised apparel. The printer has plates in different sizes to handle a wide range of textiles and creative possibilities to meet those needs. “The up-to-24-inch printing plates are easy and quick to change,” says Stachetzki. “The machine can automatically adjust the plate height to create an optimum distance between the print heads and substrate.”

Moreover, six staggered print heads with internal cooling fans ensure continuous printing operation. The novel arrangement enables white ink to be printed first, followed by orange and green, with CMYK as the top layer. Stachetzki continues: “The inks are filtered and degassed to guarantee optimum print quality up to 1,200 dpi. The built-in air filter also optimises working conditions, even in difficult environments and large production halls.”

Sustainability

The textile printing industry’s environmental focus is also growing. Inkjet printing is a greener process, but more can still be done to reduce its carbon footprint. Brother is striving to set an example to its customers by providing them with green solutions.

“We take sustainability very seriously,” says Stachetzki. “Our water-based Innobella inks are OekoTex Passport and GOTS [Global Organic Textile Standard] certified and come in nine-litre tanks with reduced packaging. The built-in ink mist filter also ensures a safe working environment for the operator.

“Thanks to our 15 years of experience in DTG printing, we are able to constantly develop our technology and create the most optimal solution for our customers, with a focus on the environment.”

The garment printing market is rapidly evolving and has become more competitive following the emergence of direct-to-film (DTF) technology – a market segment that Brother is already servicing.

Stachetzki continues: “We are investing more and more in the industrial printing sector and expanding our development and manufacturing departments.

“With this, we want to be able to continue to supply manufacturers with reliable, sustainable and production-oriented machinery that meets all the requirements of an evolving market.”

New trends

On-demand manufacturing is a high-growth production model that can reduce the environmental impact of print service providers. DTG printers can affordably print large and low volumes simultaneously, which facilitates the developing trend and, in turn, promotes reshoring. The business model has benefitted from growth in ecommerce and provides a greener alternative to mass-produced fast fashion.

Stachetzki says: “It [on-demand manufacturing] is an increasingly important area for our business. It gives producers the opportunity to expand revenue streams by targeting new markets without much effort.

“And since state-of-the-art industrial printers can now be connected to the internet, online orders can be sent to production facilities anywhere in the world using simple software solutions. This means that producers with free production capacity can also accept orders they would otherwise not have received.”

FESPA Global Print Expo takes place on 23-26 May. To learn more about Brother’s solutions, visit Stand B1-D11.

Have your say. Join the conversation and follow us on LinkedIn