-

Understanding the commercial readiness scale

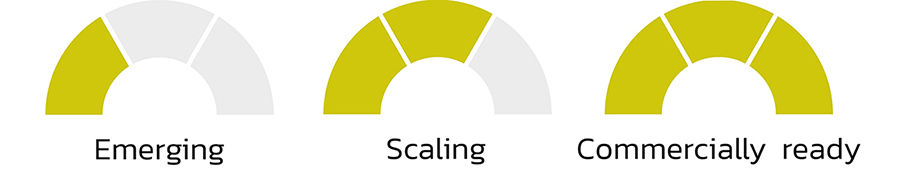

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

Sponsored by Adobe

Introduction to Digital Textile Printing

Inkjet technology remains the fastest-growing solution in the textile printing industry due to enhanced versatility, intricate print designs, and a lower environmental impact compared with analog alternatives.

Digital textile printing has established itself as a capable technology across a wide range of applications, from fashion to home textiles, and can cost-effectively print large- and low-volume print runs.

After digital textile printing technology became commercially available more than two decades ago, it was used to print samples affordably. However, following intense research and development, in conjunction with improvements to raster imaging processors (RIP), the technology can now compete with rotary screen printing in terms of speed and cost.

At ITMA 2011 in Barcelona, the first digital single-pass textile printer was introduced to enable true mass production. However, by utilizing RIP software, single-pass technology has continued to evolve and now facilitates on-demand manufacturing. The model dramatically reduces fabric, chemical, water, and energy consumption and with it the textile printing industry’s environmental footprint.

Role of RIP Software and the Adobe PDF Print Engine

With the assistance of RIP software, the market has also seen the introduction of high-volume scanning printers, which bridge the productivity gap between low-volume multi-pass and industrial-grade single-pass printers. The advantage here is that fewer printheads are required, which reduces the total cost of ownership (TOC) – a critical factor during a period of ongoing economic volatility.

Similarly, RIP software is playing a crucial role in the growth of garment decoration technology, such as direct-to-garment (DTG), sublimation transfer, and direct-to-film (DTF) printing processes.

Many of the benefits obtained by users of digital textile printers are attributable to RIP software, which maximizes efficiency and quality by controlling many aspects of the digital printing process.

A raster image processor (RIP) enables communication between a computer and a printer. It converts the design into the dots (rasters) used by the inkjet printer to reproduce the design on the textile.

While vector images can be easily scaled up or down, pixel images are dependent on the resolution of the printer. Altering an artwork’s size without considering this can result in pixelation, so vector designs are preferable, especially if a design contains text or sharp-edged graphical elements. Vector-based artwork is “resolution independent”, which means that a RIP can take full advantage of the capabilities of the press, such as resolution and variable droplet sizes However, as printers use dots to replicate color, a vector image must be rasterised into pixels which instruct the press how to jet the ink droplets onto the fabric.

Put simply, RIP software ensures that print service providers (PSPs) generate color-correct, accurate output, which can in turn boost revenue.

The Adobe PDF Print Engine enables textile printers to harness the full benefits of the PDF imaging model. It integrates the same core technologies found in Adobe's popular creative tools, such as Illustrator, Photoshop and Adobe Acrobat. It brings efficiency, consistency and precision to the textile printing workflow. With Adobe PDF Print Engine, PSPs can be more productive and deliver greater customer satisfaction by unlocking their printers’ full potential.

Overcoming Challenges in the Design-to-Manufacturing Process with PDF

By embracing the power of PDF, PSPs can address the challenges associated with digital textile printing. One of the most significant hurdles is color accuracy, which can result in costly print errors if it is mismanaged.

To combat inconsistencies, the PDF Print Engine preserves color information and metadata to ensure reliable color reproduction. With support from color palettes and ICC color profiles, PDF allows designers to unleash their creativity with the confidence of knowing their designs will be accurately reproduced on press.

Similarly, PDF supports layers, transparency and vector graphics so that designers and PSPs can easily manage jobs to streamline the production process. It also simplifies the task of handling multiple design variations, colorways and print sizes.

The digital textile printing market has enjoyed strong growth in recent years; according to data from WTiN, annual output in the roll-to-roll sector achieved a CAGR of 12% between 2015 and 2022. Annual productivity in the same segment is more than 3 billion sqm despite recent economic headwinds.

Adobe PDF Print Engine is key to a smooth transition from design to manufacturing, which lowers time-to-market and allows PSPs to meet the ever-increasing demands of modern-day consumerism, such as fast fashion. PDF enables the integration of design and production instructions within a single file. It can convey cutting outlines, print parameters, and other critical information, fostering efficient and reliable workflows.

Moreover, effective collaboration between designers, manufacturers, and printers is crucial for streamlined workflows. PDF serves as a common language, facilitating seamless collaboration by acting as a universal file format. Its compatibility across platforms and devices allows for easy sharing, viewing, and commenting on designs using Adobe Acrobat Reader, ensuring effective communication and collaboration throughout the workflow.

The digital textile printing market’s pursuit of streamlined production has enabled on-demand e-commerce to flourish. Since the pandemic, online textile transactions have risen sharply due to a growing number of online stores operating on e-commerce platforms.

Personalization is one of the trends prompting the digital transformation of fashion commerce – in which RIP software also plays a central role. While it is more prominent in the fashion space, the trend is also being applied in other application areas.

Consumers want to express their unique beliefs and values and can do that through fashion, but they need more variety on the traditional high street. Digital printing can affordably print low volumes and is therefore well suited to printing bespoke items; the technology has already captured the attention of leading brands and retailers.

Adobe’s PDF Print Engine empowers designers to personalize their prints by supporting variable printing. Whether it's a bespoke design, personal name, or dynamic content, PDF allows for the seamless integration of individual elements, enabling textile printers to create unique and engaging products.

There is also an environmental angle to consider. Some experts state that the lifespan of mass-produced fast fashion is shorter than that of a bespoke garment, which means personalization reduces the volume of fabric going to landfill.

Analog screen-printing technology often results in overproduction because of the volumes required to make it affordable. The economic impact of this for brands and retailers is evidenced in end-of-season sales. Prior to slashing prices, these same companies are forced to store excess stock in warehouses, which also erodes profit margins. Print-on-demand is a viable solution and is made possible through inkjet technology and the influence of RIP software. Adobe PDF Print Engine specifically addresses this challenge by presenting economically viable pipelines for on-demand and fast-fashion digital print production.

Leading digital textile printer manufacturers have stimulated growth over the last decade by focusing on innovation. Developments in this sector have been inspired by the digital revolution and the arrival of Industry 4.0. Automation, flexible manufacturing, increased uptime, improved efficiency, and simplified maintenance are all advantages of the digital transformation and RIP software has proven itself as a key facilitator.

Have your say. Join the conversation and follow us on LinkedIn