The roll-out of DPPs has bolstered concerns that transparency cannot validate sustainability claims – and only traceability can strengthen trust in brands. Otis Robinson speaks with experts Aware about the impending legislation.

Big brands are worried. The roll-out of digital product passports (DPPs) – in line with new European Union (EU) regulation – is set for 2026 onwards, and since many household-name brands plan their product portfolios years in advance, the time to adopt DPPs is now.

But DPPs demand product lifecycle information in an era where supply chain opacity remains at large. Many industry players know little about their suppliers beyond Tiers 1 and 2, meaning they could struggle to meet these mandatory demands. Legislators know this: the EU’s Corporate Sustainability Due Diligence directive aims to encourage “sustainable and responsible corporate behaviour”. It will require brands to have a comprehensive understanding of their supply chains.

Indeed, the mandatory nature of these legislative changes is daunting for brands. Worse still, this level of transparency still does not explicitly authenticate any green claims applied to products. Transparency, after all, does not promise traceability. Without validated claims, at worst case scenario, an opaque supply chain amid a roll-out of DPPs could prove reputationally disastrous. Brands could scramble to provide authenticated product information with very little information available to them and may end up offering misleading or incorrect information to consumers and supply chain agents.

Ultimately, without validation, sustainability claims are at risk, says Koen Warmerdam, brand director at integrity platform Aware. Controversy reigns in fashion news. Litigation against multinational clothing company H&M in 2022 alleged “false” and “misleading” sustainability marketing, citing an investigation by news outlet Quartz that claimed more than half of H&M’s sustainability profiles portrayed products as “better for the environment than they actually were and, in some cases, were allegedly completely untrue”. Though the initial claims were dismissed, further lawsuits alleged similar misrepresentations. As new legislation rolls out, it is not unlikely that more brands could come under fire for “false” or “misleading” claims attached to DPPs.

Of course, the Corporate Sustainability Due Diligence directive is pushing brands to understand their supply chains. Its function is also said to support green claims or, on the contrary, uncover the potentially dark underbelly of products as a first step to eradicating malpractice, noted sustainability solutions provider Bluesign in conversation with WTiN in October 2023. But Warmerdam notes that those aforementioned controversies highlight the need for a two-pronged approach to DPPs. Supply chain transparency is not enough: DPPs will require the authentication of product constituents and sustainability merits to validate claims, too. According to Warmerdam, this means traceability technologies will be pivotal to DPPs.

Fibre-forward DPPs

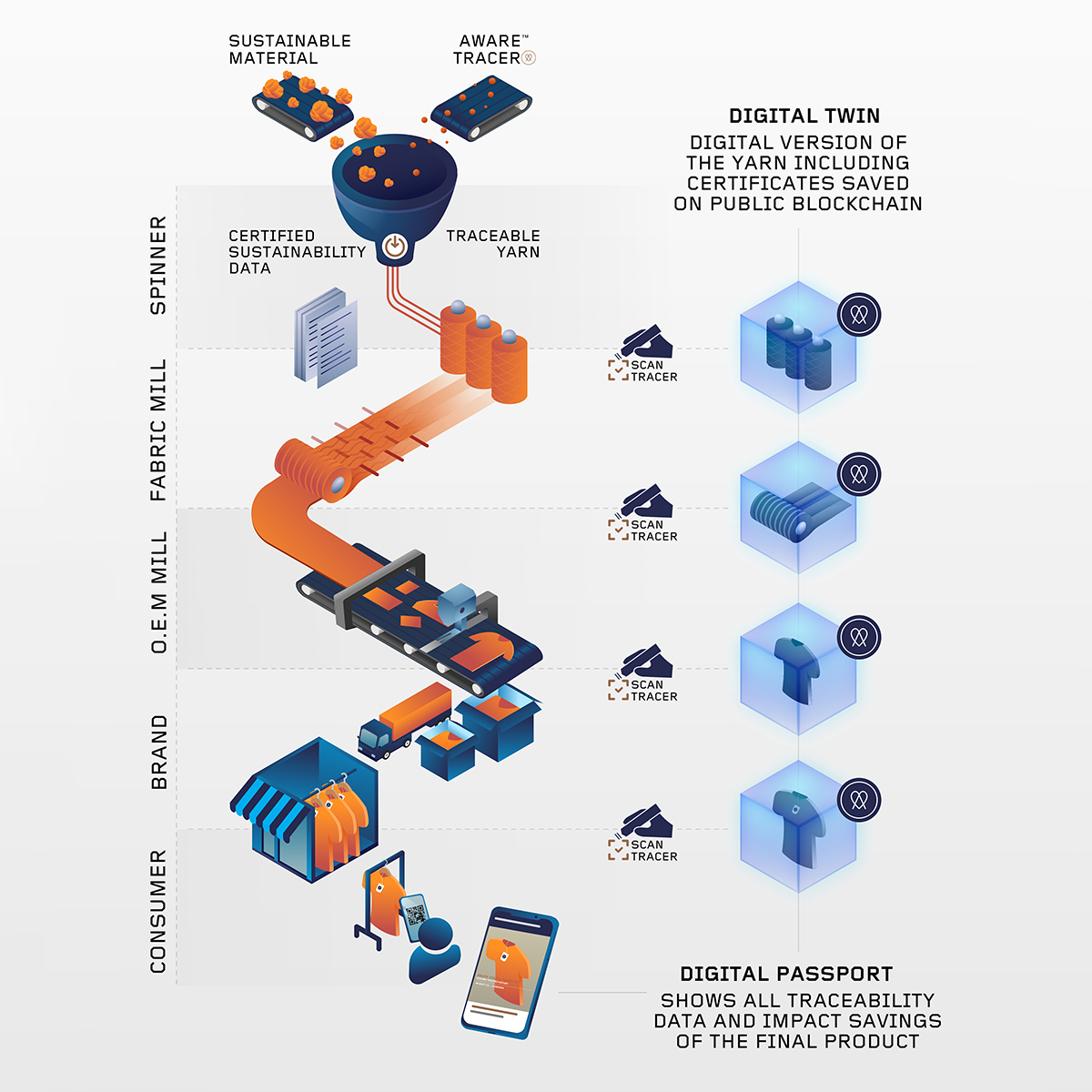

Aware, a Netherlands-based technologist, offers a tracer material that is added to products by nominated spinners. The tracer fibres are vaporised into the total composition of the material.

At this first stage, Aware technology can validate that the yarn has been produced sustainably or with recycled material, while lifecycle assessment (LCA) data that calculates the impact savings of the product is added too. At the second stage the tracer is detected by spectrum metres to confirm and authenticate the product along the supply chain as a garment is made. Blockchain is used to register every transaction, doubly authenticating a product’s physical journey.

Every transaction is visible to everyone, Warmerdam told WTiN in 2022, because “in the age of information, ignorance is a choice”. In light of the impending roll-out of DPPs, Aware has catered this solution to this legislation – what Warmerdam calls a fibre-first approach.

Warmerdam surmises product traceability should be proactive, not retroactive: “When DPPs bring in traceability, it’s always product-backwards. This needs to change. It should always be a fibre-forward tracking – to validate products as they are being made, by the people who make them, to really offer end-to-end traceability based on primary data.”

Operating with a fibre-first approach to DPPs would allow fibres to be traced throughout their supply chain journey. In other words, product constituents – and their sustainability claims – could be validated long before they become a garment in the first place.

Warmerdam explains: “As a brand, you previously had no idea what happened before your product was made. You could not see data at the fibre or yarn stages, but we validate and make that data public. But legislation is forcing us to act now. The current system is inefficient – everybody knows that. Cheating finds its way into the textile supply chain, and certifications and certificates don’t offer any direct connection to actual material [to validate it].

“The key to our solution is tokenising a product’s materials: creating digital versions, following them upstream. Every supplier adds the material producer, possible impact data. This is, finally, connected to the purchase order of the final brand, and at that moment, it activates a DPP.

“The data on this DPP – and the product itself – can now be super reliable.”

Adoption by Asian suppliers

As such, Aware believes it is imperative that the journey to trustworthy DPPs begins with fibre and yarn suppliers, particularly those in textile hubs across Asia. Consequently, the company is poised for further growth by targeting manufacturers here: the Dutch startup has secured a new funding round from Singapore-based investor Presstar Capital through a simple agreement for future equity (SAFE) investment.

Thus far, interest in Aware’s solution is strong. For some time, brands have pushed suppliers to adopt traceable technologies in their production processes in anticipation of evolving EU legislation. Warmerdam says suppliers from these countries – such as China, Pakistan, India and Bangladesh – are also “done with the current system” and aware their brands demand traceability. They too seek the opportunity to make their materials traceable, open themselves to new markets and reduce their liability in supply chain disputes. He predicts adoption will only grow.

Doubly, in turn, this adoption by Asian suppliers will solidify transparency and traceability for their EU-based customers as DPPs are rolled out.

Impact data

Implementing a fibre-forward DPP system – a transparent supply chain bolstered by tracers, with all suppliers involved in data sharing – ultimately supports the harnessing of honest impact data for a brand.

This is invaluable for building consumer trust, confidence, valuable marketing and opening avenues for sustainable optimisation. Most brands have positive intent in improving the trustworthiness and reliability of the textile & apparel supply chain. Warmerdam says: “These brands know how polluting our industry is. They want to reduce their impact. Now is the time to act.” If not for the environment, brand reputation is at risk, he adds.

Nevertheless, bad agents remain in the supply chain: “Of course, suppliers can cheat any system. If a supplier wants to cheat, it can cheat.

“But by affording suppliers the opportunity to enter the correct data and proof it, we trace and validate products, ensuring transparency for all stakeholders. This approach leaves no space for corruption or greenwashing.”

For more information, visit www.weareaware.co.

Have your say. Join the conversation and follow us on LinkedIn