-

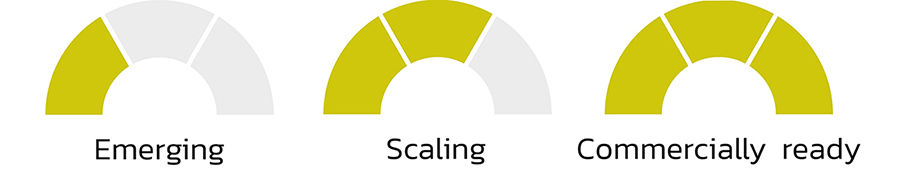

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

Denim remains popular with consumers across many generations because it is a versatile and durable material that transcends trends and styles.

The cotton fabric is used in casual, smart-casual and sometimes semi-formal attire, and is robust because of its twill weave. Denim garments are also easy to care for.

However, vast quantities of chemicals and water are used in its production, which can be harmful to humans and the environment.

The water is required to remove chemicals that can irritate the skin. These are often found in synthetic indigo – the dye that gives denim its signature colour – but its byproducts contribute to water and soil pollution if they escape into local ecosystems via wastewater.

New processes have come to market that promise to create a more sustainable denim supply chain, and others are still in development. Technology providers have different ideas about how best to create a cleaner industry, but most agree that innovation is key.

US-based full-service platform CleanKore is striving to overhaul the denim industry with its patented dyeing technology that, according to the company’s vice president of operations Ryan Ripley, “preserves the interior of the yarn and prevents the dye from penetration”. As a result, less water is used to produce denim garments, and energy is conserved. Worker safety is also stepped up because the harmful chemical potassium permanganate (PP) is eliminated.

The technology can be applied to multiple types of denim: rope, slasher, ring-spun, open end, dark indigo, sulphur top or bottom, and sulphur black.

Data

The company’s technology is now in retail stores across the globe. High-impact climate solution provider BluWin has also verified CleanKore’s mill and laundry savings in a third-party audit. It tested hand sand and laser treatments in conventional and CleanKore indigo denim and revealed that the latter, without PP, achieves a 60% reduction in water. Figures from other tests included a 57% reduction in steam, chemical savings of up to 47%, a 51% increase in productivity, and a 58% drop in greenhouse gas emissions.

Darryl Costin Jr, CEO of CleanKore, said: “We had three main objectives with the report: to get our data verified by a third party; to prove the benefits of our technology stretch beyond the elimination of PP spray and that we can assist any company regardless of its corporate sustainability initiatives and goals; and to offer a sustainable and cost-effective solution that will work in any denim mill in the world and at any garment manufacturer, irrespective of whether they focus on laser or hand sanding.”

A separate BluWin study consisted of multiple tests on indigo and black denim at one of CleanKore’s laundry partners. It says its dyeing process outperformed conventional methods on environmental issues, which subsequently lowered manufacturing costs.

It reported reduced chemical consumption by 43%, steam by 59%, water by 52.5%, and machine time – such as a washer or dryer – by 31%. CleanKore indigo dyeing also obtained an environmental impact measurement (EIM) score of 31 vs 43 from conventional dyeing.

Similarly, the results indicated that CleanKore’s black denim dyeing solution reduced water and chemical consumption by 41% and 34% respectively. The process also cut steam by 46.5% and machine time by 43% and had an EIM score of 24, which is 38% lower than non-CleanKore processes. Ripley added: “CleanKore is proven to significantly reduce costs throughout the denim manufacturing stages while lowering the carbon footprint and improving sustainability.”

Collaborative approach

CleanKore says it works with denim mills in a practical and streamlined way.

Ripley said: “We are working with more than 30 denim mills worldwide and that list is growing. It took time to build trust with them, but our promise not to introduce new equipment, chemicals, or capital expense has helped us gain traction.

“We are working with mills on trials and production runs, and our team is available to help onsite and online. It enables the mill to utilise our technology, such as converting existing fabrics to CleanKore or developing new ones.

“By removing the need to develop multiple dip versions, we also help our clients create one fabric that can produce many shades for garment manufacturers. The latter improves inventory management, shortens delivery times and allows customers to change assortment.”

One of CleanKore’s partners is Bangladesh denim mill Envoy Textiles, which participated in the BluWin trials. Tushar Tripathi, Envoy Textiles CEO, said: “We believe in sustainability alongside innovation and collaboration. The innovation should be scalable and, most importantly, cost-effective. BluWin analysis shows considerable resource savings at both mill and garment factories and lower greenhouse gas emissions.”

A barrier to success?

If innovation is necessary to secure the future of the industry, brands must be onboard. They have been criticised for their slow response to the environmental crisis. Instead, there has been a race to the bottom on cost, which has fuelled the fast fashion trend, but they are now turning a corner.

Consumers want to make more informed purchasing decisions and are calling for supply chain transparency. The risk that consumer buying habits will change has forced brands and retailers into action.

14 leading retailers, including Walmart, are selling denim garments manufactured using CleanKore technology. Millions of them are now in retail stores and at H&M, in the spirit of transparency, these products have QR codes on the label enabling customers to learn more about their production.

To learn more about CleanKore’s denim dyeing technology, visit www.cleankore.com.

Have your say. Tweet and follow us @WTiNcomment