-

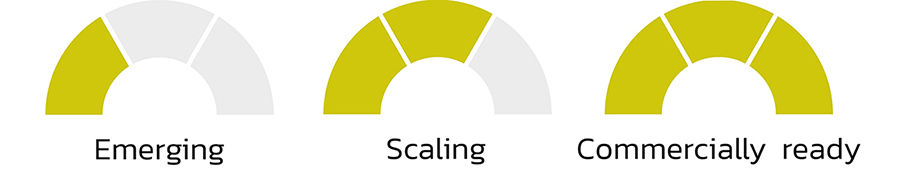

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

Sponsored by Taiwan Textile Federation

Morgen Huang, executive special assistant at functional yarn specialist, Chainlon, discusses the company’s high-performance solutions, industry challenges and opportunities ahead of TITAS 2025.

Taiwan-based yarn manufacturer Chainlon, one of the world’s most well-known and successful brands in the Nylon 6 and Nylon 6,6 sector will be showcasing its solutions at the upcoming Taipei Innovative Textiles Application Show (TITAS) at Taipei Nangang Exhibition Center in Taiwan from 14-16 October 2025. The company can be found at Booth M2402.

According to Morgen Huang, executive special assistant at Chainlon, the company’s booth will feature vibrant displays and innovative window designs that showcase its key brands:

- GREENLON® for outdoor environments

- FUN-MAX® for indoor activities and yoga centres

- GREENLON OCEAN® for swimming and water sports

Huang continues: “In addition, we will present our ESG initiatives and carbon-reduction policies, underscoring the company’s long-term commitment to sustainability. We are also introducing our advanced 3D technology, which adds value by enabling customised services to our portfolio.”

The company’s exhibit will feature nylon yarns combined with circular and warp knitting fabrics, covering a wide range of applications such as yoga and training, soccer and sportswear, golf and tennis, shirts and uniforms, as well as semi-casual wear. Huang comments: “Our nylon yarns and fabrics can meet the needs of virtually every fashion and sportswear category while maintaining both functionality and style.”

Furthermore, its Dura-fila® Nylon High-Tenacity Yarn extends into industrial uses, including national defence, automotive, workwear and outdoor equipment.

TITAS’ role in industry

TITAS plays a vital role for both Chainlon’s business and the Taiwanese textile industry on a broader scale. Huang explains: “In 2025, over 400 global exhibitors are expected, with booth numbers exceeding 1,000 and an estimated 35,000 visitors. With such a diverse range of products and innovations, TITAS has become the ultimate one-stop sourcing platform for buyers worldwide.”

Chainlon, founded in 1988, has been participating in TITAS for many years, continuously supporting the Taiwanese textile industry. “Our booth, located on the main aisle, highlights our position as one of Taiwan’s leading nylon yarn producers and circular fabric mills. We are proud to be an active member of the Taiwan Man-Made Fiber Industries Association,” Huang says.

So important is Chainlon to the Taiwan textile industry that last year, Vice President Hsiao visited the company’s booth, “showing great interest in our textile-to-textile recycled fabrics. We also welcomed many visitors from Japan, reflecting our long-standing reputation in the Japanese market. Many of our textile partners also use TITAS as a platform to strengthen relationships and discuss future collaborations.”

Ongoing industry challenges

The exhibition comes at a time when challenges for the Taiwan textile industry – and indeed the global textile industry – are rife. Economical challenges worsened by global political instability and sustainability issues to address are forcing players up and down the supply chain to assess their offering and innovate. One of the main challenges for Chainlon is the ongoing tariff barriers. “The Taiwanese government continues negotiations with the US government, but the environment remains difficult for textile exporters,” Huang explains. Adding: “To stay competitive, we are continuously improving our R&D capabilities.”

The company also operates a fabric factory in Vietnam to diversify risks and ensure faster delivery. “By combining functional yarns from Taiwan with Vietnamese production capacity, we can provide clients with a wide selection of swatches and fabrics promptly. This win-win approach is deeply embedded in Taiwanese textile industry strategies,” Chainlon continues.

Digitalisation is another way in which companies can confront ongoing challenges, with the flexibility and operational efficiency digital transformation can provide. Huang says: “Digitalisation has been one of Chainlon’s key strategies in recent years. We have digitised fabrics using advanced software to showcase 3D effects on different styles. Moreover, this technology allows brands to visualise fabrics directly on prototypes, significantly improving the design and development process.” And, at the company’s TITAS booth, visitors will be able to instantly access detailed product information by scanning a QR code at the booth.

Themes, products & services

Intelligent manufacturing is one of the key themes of TITAS, often synonymous with digital transformation. Other key themes of the show are sustainability and functional applications.

In-line with the exhibition’s sustainability theme, Chainlon will be introducing its FUN-MAX® AM Oyster Shell Series. This is a series of functional yarns that use calcium carbonate from oyster shells. Huang explains: “After high-temperature calcination, it becomes calcium hydroxide, releasing alkalinity and active oxygen to effectively disrupt bacterial structures, achieving antibacterial and deodorising effects.”

And, its GREENLON® CL & Anti-UV Series is infused with low specific heat mineral powder to quickly dissipate heat, providing a lasting cooling effect.

Chainlon’s GREENLON®Eco-Friendly Yarns are made from pre-consumer off-grade textiles, reproduced into 100% recycled yarns without chemical treatments. These materials undergo multiple processing stages, giving textile waste a second life and enabling their use in diverse fabric applications, Huang says.

“In addition, our GREENLON OCEAN® Fishing-Net Mechanical Recycled Series uses mechanical recycling to transform discarded fishing nets into high-value yarns, which are then applied in clothing, footwear and backpacks.”

This commitment to quality and sustainability is why many customers choose Chainlon as their long-term partner, trusting the company’s six core values: sustainability, service, diversity, integrity, innovation and teamwork.

These more sustainable technologies are also applicable to the functional applications theme. Elsewhere for functional applications, Chainlon’s FUN-MAX® Nylon Functional Yarn Series features “unique cross-sections designed for luster, warmth, moisture absorption and windproof properties. Its petal-shaped grooves allow for efficient moisture absorption and evaporation, keeping fabrics naturally dry,” Huang says.

Additionally on show, Chainlon’s FUN-MAX® HL Light Heat Series uses metal oxides to absorb sunlight and near-infrared rays, converting them into heat energy to create a warming effect.

Future

Taiwan is renowned for high-performance, functional sportswear materials and Chainlon lives up to this reputation. Huang says: “Since founding Chain Yarn Vietnam Co., Ltd. in 2015, we have accumulated extensive technical experience and built strong capabilities. We provide a one-stop service from design and development to spinning and finishing, offering our clients a complete solution.” And this, Huang connotes, will long continue at the company. “We always put our customers first. In today’s fast-moving market, short lead times and product diversity are crucial. We not only provide high-quality mainstream products but also collaborate closely with clients to develop unique items.”

Huang concludes: “Our goal is to meet customer needs while building strong, long-term partnerships that drive mutual success.”

Visit Chainlon at TITAS from 14-16 October 2025, Booth M2402.

Have your say. Join the conversation and follow us on LinkedIn