Sponsored by Taiwan Textile Federation

Ad.by TITA

Across global textile supply chains, pressure continues to build for manufacturers to reduce environmental impact and demonstrate credible action in addressing waste.

As a result, Taiwan’s material innovators have responded with a wave of fibre and fabric technologies that point to a more sustainable future. Their work reflects both local priorities and wider shifts in design practice, regulation and consumer behaviour, which together shape demand for low impact performance materials.

Agricultural waste

One area of focus is agricultural waste. Woven and knitted items manufacturer Grandetex, for example, has taken interest in cacao byproducts and has developed SECAO®, a textile material created from recycled waste cacao shells.

Taiwan’s cocoa processors produce organic waste, and the byproduct of these processes – cacao shells – have often ended up in low value streams. By turning them into a functional ingredient for fibres and fabrics, Grandetex signals how agricultural systems and textile value chains can be linked in ways that support rural livelihoods and reduce waste. SECAO® also acts as a response to growing demand for natural sources that derive value from local resources while lowering reliance on virgin inputs – ultimately, supporting the establishment of circular systems.

Stretch materials

Stretch materials are also under scrutiny for their misalignment with sustainability efforts. Elastane remains difficult to recycle and slow to biodegrade, and its presence in blends complicates end-of-life processing.

However, textile company Hermin has been exploring alternatives for several years and has now commercialised Bouncy Fabric, a series of biodegradable stretch textiles made from cotton, modal and Tencel.

By replacing elastane with a natural or regenerated fibre-based solution, Hermin aims to provide brands with stretch fabrics that hold performance while offering a clearer pathway to more sustainable waste management.

Recycled synthetics

Taiwan is also home to extensive expertise in recycled synthetics. Li Peng is among the companies pushing forward with high quality circular polyamide. Its newly developed Forever Yarn was shown at the 29th Taipei Innovative Textile Application Show (TITAS) and is made entirely from recycled fishing nets.

Discarded nets are a persistent marine pollutant and the Li Peng initiative aligns with both regional marine waste recovery programmes and international brand commitments to integrate ocean bound plastics into material mixes. Li Peng has focused on durability and consistency, the company says, emphasising that Forever Yarn delivers the mechanical strength expected of premium nylon textiles.

N-Stars has taken a similar direction. Its NetPlus® material is also produced using reclaimed fishing nets and is designed for applications such as outdoor gear and accessories. And by ensuring traceability along the NetPlus® recycling chain, N-Stars aims to give brands added verification and authentication that the fibre genuinely supports ocean restoration projects in an industry marred by greenwashing. In application, NetPlus® has received interest from designers who are under pressure to demonstrate carbon reductions across product portfolios and who are increasingly adopting recycled synthetics.

Chemical recycling

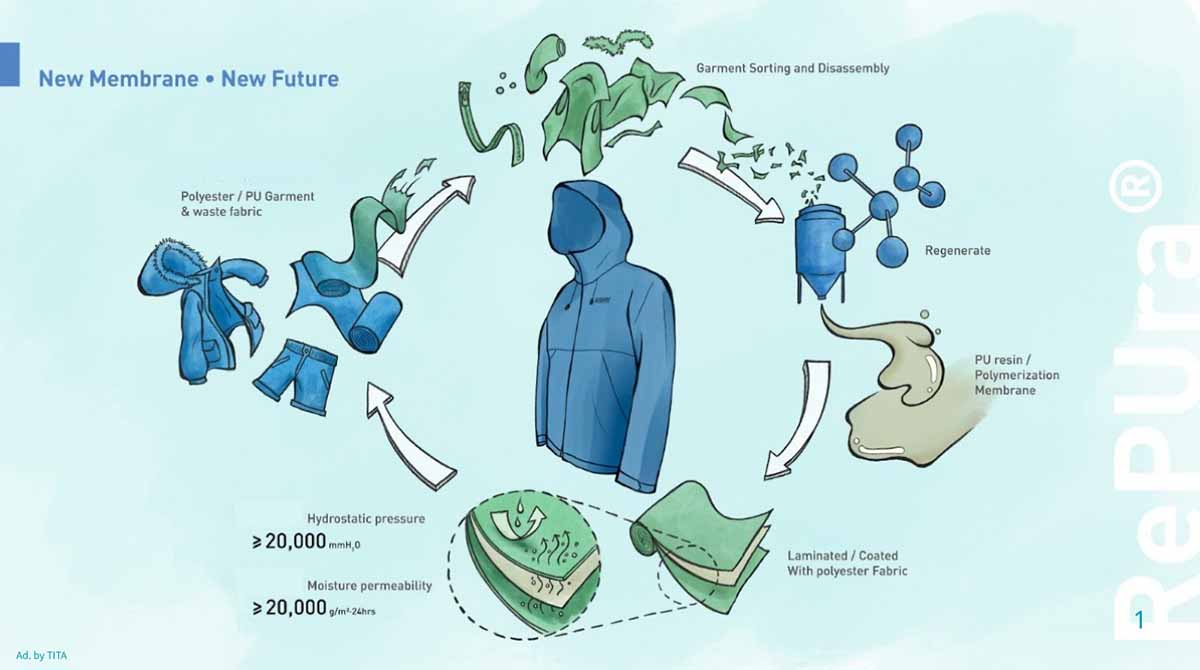

Chemical recycling is another frontier in which Taiwanese innovators have placed their efforts. Singtex, for example, offers RePUra™, which it describes as the first innovation to solve the long-standing challenge of recycling polyurethane membranes and elastane.

These components have been entrenched in sportswear and outdoor clothing for decades, yet they remain difficult to recover once bonded into complex laminates. RePUra™ tackles this issue by enabling separation and recycling, which opens new potential for circular performance wear.

This innovation arrives as global legislators push for improved recycling rates and for products that are designed with end-of-life solutions in mind.

Performance materials and membrane specialists

Performance materials suited to extreme weather are also advancing. WidePlus has developed miniR® to help brands address climate change and shifting environmental conditions.

The company notes that miniR® combines protective qualities with reduced impact, supporting designers who require high performing fabrics without relying solely on virgin petrochemicals. As extreme weather conditions become more frequent, WidePlus expects greater interest in materials that offer thermal stability and weather protection yet still hold credible sustainability attributes.

Taiwan’s innovation landscape also includes membrane specialists. Wildbear has developed TPE and TPU membranes that carry eco-friendly certification.

These membranes offer waterproof and breathable performance and are positioned as a lower impact alternative to traditional options that rely on complex chemistries. Brands working in outdoor and performance sectors have been searching for membranes that meet rising environmental standards while retaining functional integrity, and Wildbear aims to meet this requirement.

Shaping a circular textile future

Overall, together, these technologies show why Taiwan remains a significant contributor to global textile innovation.

Local manufacturers continue to align material development with environmental objectives and regulatory direction, creating fibres and fabrics that help brands adapt to a market that expects better end-of-life waste management, sustainable credentials and strong performance.

As climate and resource pressures intensify, these companies demonstrate how regional expertise can help shape a more resilient and circular textile future.

Have your say. Join the conversation and follow us on LinkedIn