The Textile Innovation Podcast speaks with Simon Kew, COO of Sparxell.

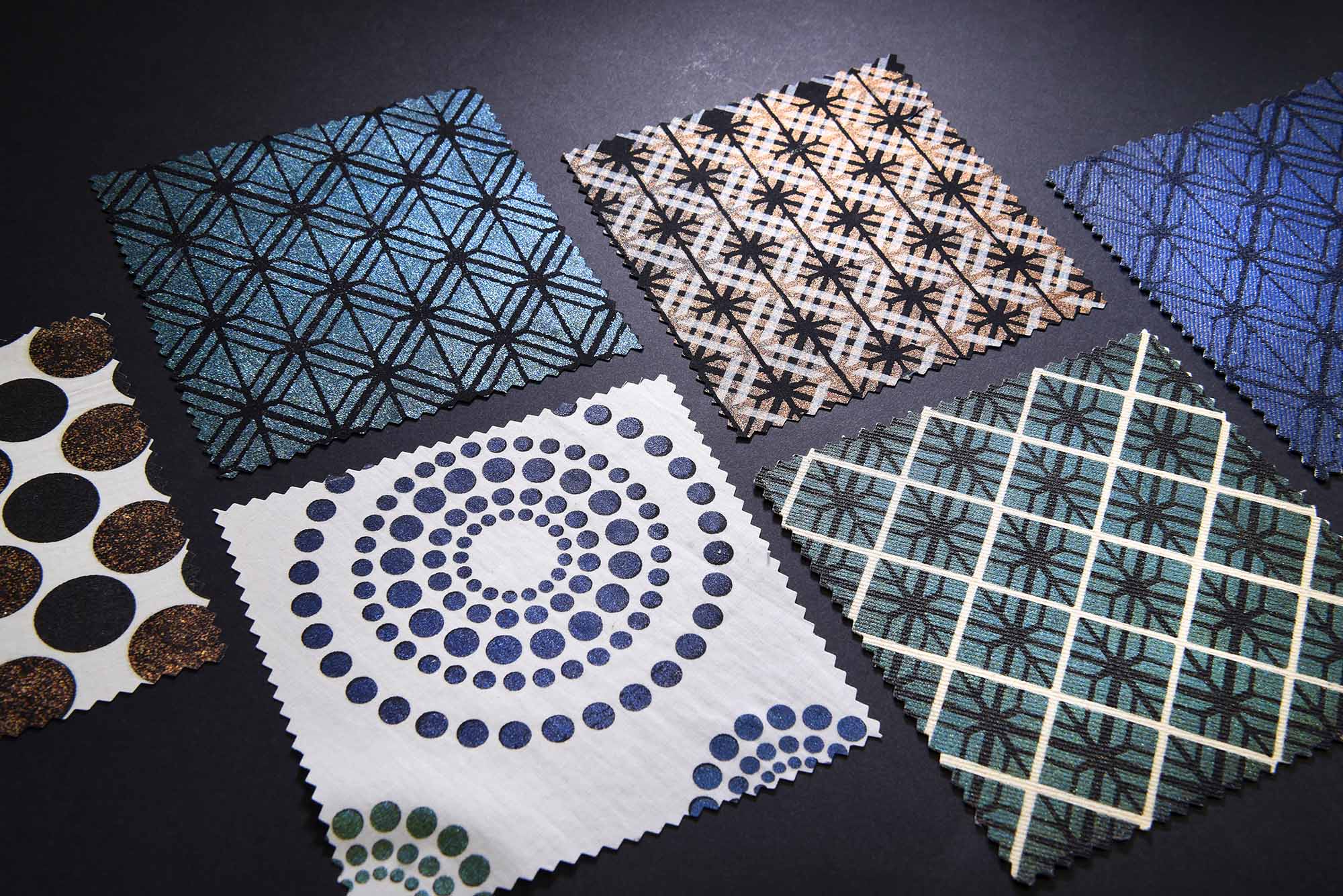

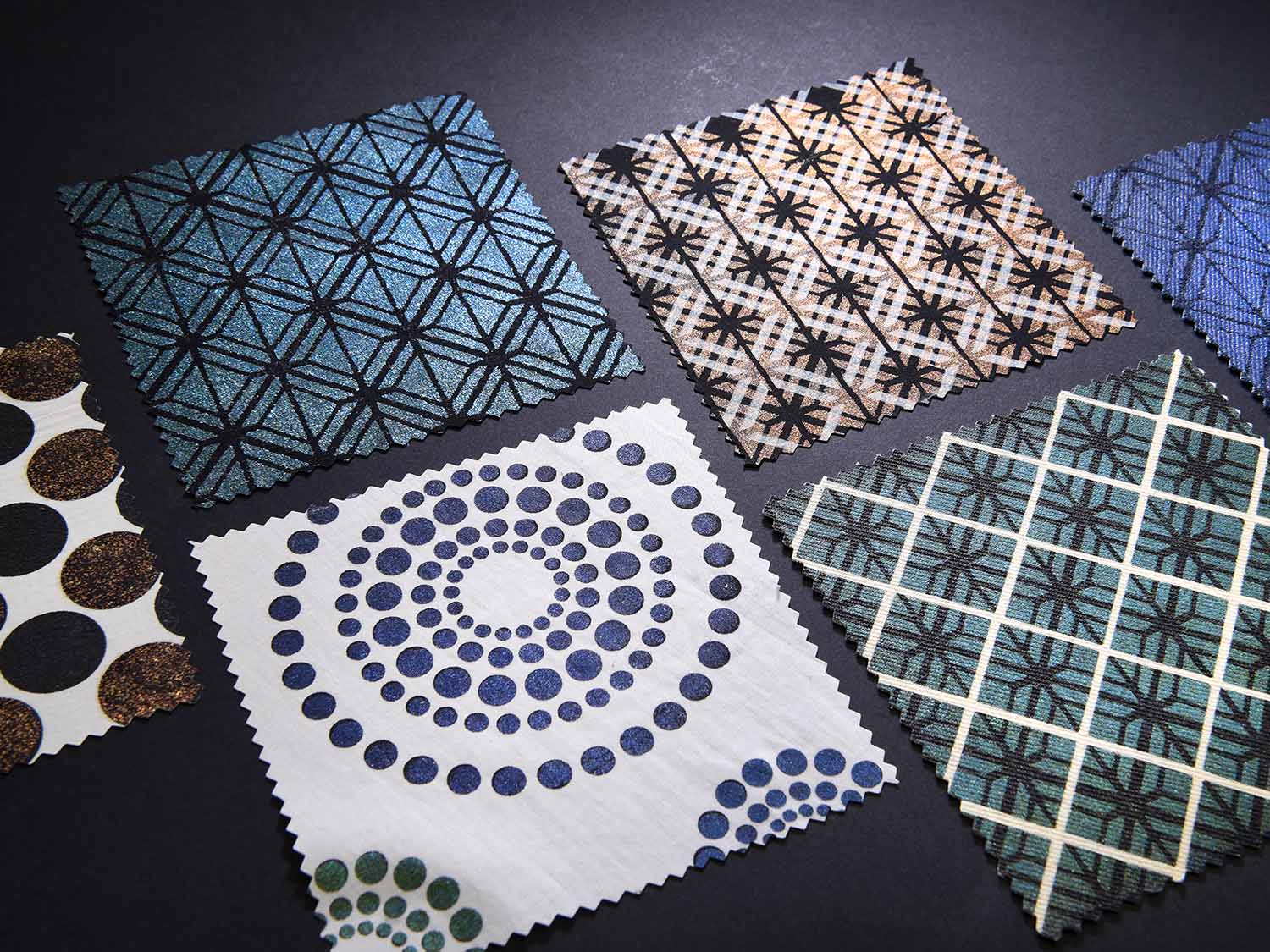

Sparxell develops next-generation colours and effects by providing 100% plant-based performance colourants. Spinning out from the University of Cambridge after years of research on biomimetic photonics and structural colours, Sparxell aims to eliminate toxic chemicals from colouration.

With GHG emissions currently predicted to triple by the middle of the century, the fashion industry is far off course to reach Net Zero, as set out in the Paris Agreement. In this episode, Simon Kew, COO at Sparxell, and Canopy member, speaks to WTiN about decarbonising and detoxifying manufacturing in the textile industry and what this means for the whole value chain.

Additionally, Kew has recently launched a book ‘The Path to Net Zero for the Fashion Industry’. He explains how the book presents quantitative science-based evidence to understand where greenhouse gas (GHG) emissions emitted by the fashion industry are generated. He also speaks about the strategies needed to achieve decarbonisation, which he sets out in the book.

For more information, please visit sparxell.com. To find out more about Kew’s book please visit, routledge.com.

You can listen to the episode above, or via Spotify and Apple Podcasts. To discuss any of our topics, get in touch by following and connecting with WTiN in LinkedIn, or email aturner@wtin.com directly. To explore sponsorship opportunities, please email sales@wtin.com.

Have your say. Tweet and follow us @WTiNcomment

-

Transcript

This transcription has been AI generated and therefore may have some inaccuracies.

Ep. 125: Decarbonising the textile value chain

The Textile Innovation Podcast speaks with Simon Kew, COO of Sparxell.

WTiN: Hello and welcome to Textile Innovation, hosted by WTiN. My name is Abi and I'm the Features Editor and your podcast host. Each month we will be joined by a special guest. So join me and my colleagues as we deep dive into what's new, what's interesting, and what unmissable innovations have hit the market recently. We cover everything on the podcast, from sustainability to startups and the latest research and development. Plus, we quiz the experts in the field about their products and ideas across the huge spectrum that is the textile industry. So no matter what your interest is, WTiN have you covered and we can connect you to everything you need to know right here from our central hub in the UK.

In this episode, I am joined by Simon Kew, COO at Sparxell. Sparxell develops next generation of colours and effects by providing 100% plant-based colourants. During the episode, we discussed decarbonizing and detoxify manufacturing in the textile industry and what this means for the whole value chain. We also touch upon Simon's recent book, which is now available, The Path to Next Zero for the Fashion Industry.

Hi, Simon, thank you for joining me today on WTIN's Textile Innovation Podcast. You have a varied and interesting background within textile manufacturing, as a member of Canopy and being involved with implementing new technologies. Please could you tell me about your background to date and your areas of interest?

Kew: Hi, thanks for the question. So in terms of my background, I'm a chemist by original training. And I've worked across a lot of different industry sectors, so biotechnology, pharmaceuticals, consumer products, food and chemicals. And in all those industries, I've been involved with taking new innovations out of the laboratory and into commercial manufacturing. And I've really been focused on the textile industry over the last five years or so, where I've got very interested in the opportunities for decarbonisation and detoxification of textile and fashion manufacturing.

WTiN: That's great. Thank you so much. That's really interesting. And how did you get involved with Sparxell and what are you currently working on?

Kew: So Sparxell is really focused on delivering the next generation of bio-based, plant-based colorants. So we're looking to replace dye stuff, metal, mined minerals, chemicals which are generally quite harmful with 100% plant-based alternative. And what we're doing, which is really unique, is delivering high-performance colours whilst also being 100% plant-based, biodegradable and sustainable.

WTiN: That's really interesting. I know there's so much talk at the moment in the industry about how toxic traditional dye methods are and moving to more sustainable alternatives. So could you tell me what opportunities you see in the industry for next generation colours and effects moving forward?

Kew: Yes, so colouration is about the most polluting aspect of the textile and fashion industry for a number of reasons. One is the processing technologies they use today and secondly are the chemistries they use today. What we're aiming to do is really use existing manufacturing capabilities that already exist in textile industry and drop in a replacement colourant technology which allows us to eliminate many different harmful toxic materials that are used in textile manufacturing and also innovate in terms of the process to reduce water consumption and wastewater emissions.

WTiN: In terms of decarbonizing and colouration it presents significant challenges for the textile industries. What are some of these barriers that you face when it comes to this and the elimination of toxic chemicals and how does Sparxell offer solutions to tackle this problem? So it's a lot of questions in one.

Kew: Yeah, so in terms of the issue of colouration, it's really very much driven by the synthetic chemistry used to dye fibre. So if you look across polyester, cotton, nylon, these fibres are all dyed using processes which require a lot of water and typically a lot of heat in order to apply the dye stuff and then wash off the excess. So in terms of what we're doing at Sparks is we're really looking to use alternative routes to get colour onto the fibre, which are much lower in energy and lower in waste water. But fundamentally, we're looking to really change the pallets of materials that are used in textiles in general. So that also includes reducing the use of synthetic fibres like polyester.

WTiN: Are you able to comment on the progress and future of digital manufacturing processes and could these further advance sustainable technologies and the path towards net zero?

Kew: Yes, so digital manufacturing in general has a huge role to play, I think, in improving the sustainability of the textile industry. There are many different aspects to that. One is supply chain optimisation, reducing waste, making more of the products that people want. The textile industry has a huge issue with overproduction and the poor linkage between manufacturing and consumption. In terms of specific manufacturing technologies, the technologies such as digital printing, which allow you to make on demand, which reduce the amount of waste. But there's also some emerging technologies, like 3D weaving, 3D knitting, where digital technologies are used to create products to shape, rather than having to cut out from fabric. And there's some very interesting innovators such as Smartex AI, who are based in Portugal, who are looking at using essentially process monitoring equipment, which is looking at quality in order to bring a much more holistic digitalization of a manufacturing process.

WTiN: I do know Smartex AI, they're doing fantastic things. It's really interesting to see how manufacturers are using AI and digitalisation more and more these days. And looking further into this, you have recently launched a book titled The Path to Net Zero for the Fashion Industry. Could you tell me a bit about the process of writing the book and some of the key findings that you uncover, subsequently from that, the implications that this has on the fashion industry?

Kew: Yeah, yeah, so the reason for writing the book was really the fact that I recognised there was no single place to find an analysis of energy consumption and carbon emissions from fashion and textile manufacturing. So the purpose of the book was to really bring together all the publicly available information on this topic and provide an integrated analysis, which then allowed recommendations and strategies to be developed to support the overall goal of aligning the fashion industry with net zero and decarbonizing the industry. In terms of the implications for the fashion textile manufacturing world, we identified several different key strategies to focus on, so it's not a single answer. But the book was really written to provide a kind of directional roadmap for how the industry could go about aligning with net zero, which is essentially a multi-decade endeavour and something which was going to require a huge amount of transformation in manufacturing.

WTiN: Throughout the book, you present five strategies that can be deployed to reach the Paris Agreement's net zero by 2050. Could you tell us what these five strategies are?

Kew: I can, yes. So in terms of strategies, they were really developed through doing quantitative analysis of the sources of energy consumption and GHG emission in textile manufacturing. And so the number one strategy that was identified is to decarbonize the energy supply to the industry. So this is a relatively, let's say, obvious strategy in a sense.

But one of the main issues in the industry is a lot of the manufacturing occurs in countries where there's a high usage of coal. And also, their electrical grids are powered by a lot of fossil fuel sources. So there's an intrinsic issue in the industry, which is that a lot of the manufacturing occurs in high GHG emission countries, in terms of GHG emissions per unit of energy. So that's, let's say the number one thing the industry can do to decarbonize is to change its sources of energy. In terms of the second strategy, the level of consumption in the fashion industry is increasing very rapidly. And you can look at many ultra-fast fashion and fast fashion brands which have emerged in the last decade. The per capita consumption of textiles and fashion products is going up very quickly in many different markets. Constraining this consumption is a key way to reduce the overall emissions of the industry. And some of the forecasts are that by 2050, the consumption of textile fibre might be two and a half or three times higher than 2022, which is really, yeah, intrinsically, it's very difficult to deal with, you know, whatever you do, essentially. And so that was really the second recommendation. And then in terms of maybe a bit more specific stuff around manufacturing technologies and materials. So in the book, there's a lot of focus on decarbonizing the materials palette through increased use of bio-based materials. And that includes bio-based colorants, bio-based chemistries, in order to move away from fossil fuel extraction, not just for the reason of reducing fossil fuel extraction, but many of the synthetic chemistries are inherently high in carbon footprint, you know, synthetic fibers are one example, synthetic dyes are another. And then the second area of focus was really on looking to decarbonize the coloration transformation that occurs in the textile industry. And that includes preparation for dyeing, bleaching. It includes dyeing process itself and also the finishing process. So there's a lot that can be done with new technologies to really reduce energy usage and colouration, you know, which is the number one single energy use in the industry.

WTiN: I imagine you had so much research and insight to go through to write the book and after writing the book and obviously your work throughout the textile industry, your work with Sparxell, what technologies are you most excited about moving forward? Is anything in particular that's coming to the surface at the moment that you are really hopeful and excited for?

Kew: So I think there's a lot coming through. There's certainly no shortage, if you like, of innovations coming through into the textile field. Yeah, there's a, let's say, well-documented need to really enable these inventions to get to scale and be implemented by large fashion and textile brands. In terms of the innovations that I'm most excited about, I think it's really very much towards the potential for transition and material palette. So I see the enablement of plant-based, bio-based fibres, chemicals and colourants in the industry as being a really good long-term solution to lots of different areas. So from the toxicity of manufacturing, where you're dying and reducing a lot of effluent in local markets, to the emission of synthetic microfibers into the environment, which is happening in lots of different places in the manufacturing domain, but also end of life. And I think just in general, the replacement of synthetic materials, fossil fuel-based materials, or bio-based materials, has the potential to really transform a lot of product design and overall sustainability profile of many different fashion products.

WTiN: In terms of those opportunities coming through that you have identified, what do you think the biggest challenges are facing the industry in terms of implementation?

Kew: So I think in terms of the fashion and textile industry, the structure of the industry is virtually unique in the sense of having a very highly capable and highly fragmented supply chain that's almost very little of it that's actually owned by the fashion brands or the final brands. So if you were to compare the fashion industry with the consumer products industry, the consumer products industry would typically own all of its manufacturing assets back to the raw materials, whereas in fashion industry, that's very unusual.

That does happen from time to time. And so it means there's fundamentally this tension between a fashion brand who's looking to deliver top quality design and high quality at the lowest possible cost with a manufacturer who's being asked now really to decarbonise and detoxify the manufacturing processes that they're using. So, you know, so one of the key barriers, if you like, is the enablement of some of the resources that are in control of fashion brands to be distributed amongst the supply base in maybe more equitable fashion, such that you could see more long-term investment in new machinery and new materials.

WTiN: Thank you, that is really insightful. And finally, Simon, my final question is, going back towards Sparxl, what is the company's vision and aim for its latest advancements in the textile and fashion industry?

Kew: So our aim as a company is really to be the future of colouration in the fashion industry and in many other industries as well, actually. So we're applying our technology across multiple industries. And the future for us is a coloration platform that has 100% plant-based ingredients. It has high performance. So unlike many other biocolourants, which are in general quite poorly performing, we're looking to deliver high performance and really deliver benefits across the whole value chain for the end user of the material. So whether it's the manufacturer that makes you lower costs, whether it might be the consumer who has a less toxic product that they're wearing or consuming, or whether it's the manufacturers or waste disposal companies who are dealing with the product to the end of life, you know, making that much more, much less toxic and much more sustainable.

WTiN: Thank you so much. It's really interesting to see how every step along the supply chain at the moment, there is so much innovation coming through, and it's great to see what will happen in the future. Thank you so much for joining me today on WTiN's Textile Innovation Podcast.

Kew: Thank you very much for inviting me on, Abi. Nice to talk to you.

WTiN: Thank you so much for listening. If you have any questions or want to learn more, you can follow us on LinkedIn at World Textile Information Network. Or you can contact me directly at content at wtin.com. If you are interested in sponsoring Or you can contact me directly at content at wtin.com. If you are interested in sponsoring an episode of the podcast, please email sales at wtin.com. Thank you and we'll see you next time.