-

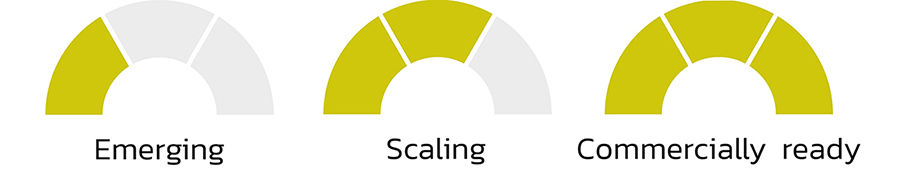

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

Overview

Sponsored by Coats Digital

Title: Sustainable manufacturing 2.0 with AI - WTiN & Coats Digital Fireside Chat

Date: Tuesday 25 November 2025

Duration: 51 minutes

Have your say. Join the conversation and follow us on LinkedIn

Summary

The whole of the global textile & apparel supply chain is under immense pressure to transition to sustainable manufacturing and more circular practices, while improving efficiency and maintaining profit margins. This challenge requires a radical shift in operational strategy to embrace digitalisation across the industry.

This Fireside Chat explores the opportunities that arise from this challenge, particularly as the advantages of artificial intelligence (AI) continue to grow along the supply chain. Taking this into account, the Fireside Chat uncovers how digital tools can be utilised to increase productivity and profitability. Featuring insights from Coats Digital's Director of Global Brands, Jamie Symon, and Florian Pohlmeyer, Head of Digitalisation at RWTH Aachen University, the session assesses how and why investing in digital capabilities is now a fundamental prerequisite for resource efficiency and waste reduction.

Watch now to explore how AI is redefining textile and apparel manufacturing processes and how you can benefit.

Speakers:

Jamie Symon

Director Global Brands, Coats Digital

With over 15 years of experience in industrial design and manufacturing software, Jamie helps fashion and apparel businesses leverage digital tools to optimise design, production and efficiency. He’ll share how digitalisation is reshaping the industry – driving creativity, productivity and sustainable growth.

Florian Pohlmeyer

Head of Digitalisation, RWTH Aachen University

Florian leads pioneering research focused on enabling a sustainable, fibre-based future. His work includes developing a data space for the textile industry to enable digital transformation and sovereign data exchange. Florian brings deep expertise in digital and sustainable transformation, textile waste recycling and nonwovens innovation.

-

Transcript

This transcription has been AI generated and therefore may have some inaccuracies.

Sustainable manufacturing 2.0 with AI - WTiN & Coats Digital Fireside Chat

This Fireside Chat explores the opportunities that arise from this challenge, particularly as the advantages of artificial intelligence (AI) continue to grow along the supply chain.

(Madelaine Thomas)

So hello, everybody, and welcome to this Coats Digital Fireside Chat organized by the World Textile Information Network in partnership with Coats Digital. I'm your host, Madelaine Thomas, Head of Content here at WTIN. Thank you for being with us to discuss how and why investing in digital capabilities is now a fundamental prerequisite for resource efficiency and waste reduction. And importantly, how AI is redefining textile and apparel manufacturing processes, and how you can benefit. Joining me for this discussion is Jamie Symon, Coats Digital's Director of Global Brands, and Florian Pohlmeyer, Head of Digitalization at RWTH Aachen University. Before we begin, just a quick note to say we encourage questions from you, our audience.(Madelaine Thomas)

So do put any questions you have for Florian or Jamie in the Q &A function provided on Zoom, and I will pose them to them. Do take advantage of this access to them while you can. So to begin, I'd like to welcome both Jamie and Florian and ask them to each tell us a little bit about themselves and the work that they're doing. Jamie, thanks for joining us. Welcome.(Jamie Symon)

Yeah, thank you very much. Yeah, so as mentioned, my name is Jamie Symon. I'm based in the UK. I have a global role working with brands, with Coats Digital. My background really is over the last 20 years having worked in digital transformation, primarily in the apparel space, but also in automotive furniture and aerospace. So trying to understand and connect the tools of those different spaces are using and apply that more to the apparel industry.(Jamie Symon)

My background has been in CAD and machinery and planning tools and now found myself in a great position working at Coats Digital to efficiencies across that and introduce our AI tools, our exciting new AI tools.(Madelaine Thomas)

Thank you, Jamie. And Florian, welcome. Thanks again for being with us today.(Florian Pohlmeyer)

Yeah, thank you, Maddi. I'm happy to be here today. Yeah, as mentioned, my name is Florian Pohlmeyer. I'm leading the digitalization activities here at our Institute for Textile Technology at RWTH Aachen University. And I'm basically working at the intersection of research, the industry, and entrepreneurship and new startups, for example. Right now, my focus and the focus of our research is transforming industrial value chains towards systems that are digital and sustainable.(Florian Pohlmeyer)

And in the textile sector, for example, this means developing the foundations for transparent materials, for flows, for data -driven production, for new business models. Yeah, going beyond just incremental optimizations. And my role is basically about building bridges, so between materials in the textile industry, the data about those materials, and of course, the people working in the value chain. And my work or our works combines always this technological understanding of the basic technologies, and the system design and organizational change which is needed for enabling companies to, in the end, become resilient and more future -proof. I'm really looking forward to today's fireside chat with you and Jamie.(Madelaine Thomas)

Thank you. Florian. It's great to have you with us. So before we get into that discussion, we're going to share a couple of polls. So studio team, if you don't mind sharing those polls for everybody, if you don't mind answering those for us. Perfect.(Madelaine Thomas)

Thank you. So are you looking to digitally transform your manufacturing operations? Yes, no, or is that currently in progress? So I'll just give a few seconds for that to be answered. OK, thanks, team. We'll now go to that second poll, if that's OK.(Madelaine Thomas)

Thank you. So do you plan to leverage AI to optimize your operations? Yes, no, or maybe. So again, just a few more seconds. Thank you very much. OK, let's have a quick look at the results if we can, Lucy.(Madelaine Thomas)

OK, so do you plan to leverage AI to optimize operations? OK, so almost 70 % said yes. So you are in the right place. 29 % said maybe, maybe that'll change by the end of this, Jamie. And 3 % no. Really interesting to know why.(Madelaine Thomas)

Great. Thank you. So we'll get in to the discussion now. We'll start with you, Florian. Can you provide us with an overview of where the industry is in terms of digital transformation currently and how important digitalization is for the textile and power manufacturing supply chain?(Florian Pohlmeyer)

Yeah, I think the result of the poll now basically showed which is also my understanding of the progress we see right now. So I would say that digital transformation and textiles is progressing. So companies start to use technologies, for example, but it's still very fragmented on the usage of different technologies and the technologies itself. I see that most companies or many companies have already digitized, for example, their machines or their quality processes. But other aspects like materials flows, product data, lifecycle information, for example, or high quality data for artificial intelligence remain largely disconnected.(Florian Pohlmeyer)

So we have a lot of data, but it's basically disconnected to really use it and gain knowledge out of the data. But on the other side, I would say that digitalization is becoming more and more essential because the industry is not just moving to optimize their current processes, but we see many different other transformation processes right now. So for example, circularity, multi feedstock systems, adaptive production to smaller amounts of production, for example. And without the transparency and data, for example, the digital product passport to get to this transparency in the value chain. We will just not reach those goals. This is my very strong opinion.(Florian Pohlmeyer)

So, in short, I would say that digitalization is no longer just an efficiency tool. It is more like the foundation for resilient and new textile ecosystems, in my opinion.(Madelaine Thomas)

I like that, that it's more of a foundation now. Jamie, what do you see in the industry at the moment with digital transformation amongst brands in particular, you know, the area that you're working in, and what do you see as those key drivers?(Jamie Symon)

Yeah, I think Florian, you kind of hit the nail on the head, really, in terms of connecting that supply chain, using that data. We are moving into a very uncertain time. With new legislation, as you mentioned, Florian, with the Digital Product Passport, the DPP, which we keep hearing about, and we're all working towards that. Tariffs obviously continuing to change the fashion manufacturing landscape. and new technologies constantly emerging. I think really from 2026 onwards, the companies that come on top are really going to be those that embrace technology early on.(Jamie Symon)

So there is a step -by -step process to connecting this full value chain. I think those that embrace that technology have those links ready to go and are so that they can react quickly when markets do change, and they will very quickly. The ones that can adapt quickly, that can change their manufacturing, that can understand what's going on throughout the world in terms of cost, labor costs, tariffs, understanding where products are, they're the ones that are going to come on top. So I think really, it's going to be primarily about agility.(Madelaine Thomas)

And Florian and Jamie mentioned, you know, that we're kind of going into uncertain times. What impact are the current industry challenges having on digital transformation? You know, if you think about the ongoing tariff challenges at the moment, how can AI and other digital tools provide solutions for these challenges?(Florian Pohlmeyer)

Yeah. At first, I would say, of course, all these industry challenges, Jamie mentioned, for example, the tariffs, but we see other challenges like volatility in the supply chains, rising energy costs, uncertainty in raw material consumption, recycling and so on, are of course slowing down the traditional operations right now. But I think, on the other hand, they are or should accelerate the digital transformation process, on the other hand. So I think that companies more and more realize that they cannot compensate those challenges just with the, let's say, traditional cost cutting alone. So they need more transparency, faster decisions, for example, and just more resilience in the entire value chains, not just in a single companies. And I would say that there are like three ways in which AI or digitalization in general can help.(Florian Pohlmeyer)

So first, it's about visibility in the value chains in the company. So visibility and transparency, for example, which enables companies to react to those challenges faster. Second would be like in this forecasting area, for example, forecasting demands more precisely the sourcing energy usage and so on. And the third, we mentioned it earlier, the digital product passport is one example, is about availability. of high quality data with products and with processes on the other side. So yeah, the challenges are there, they are significant.(Florian Pohlmeyer)

I think, on the other hand, they make digitalization and AI not just this nice to have tool, but a structural necessity in the value chains in the next years.(Madelaine Thomas)

Thanks, Florian. Jamie, with these challenges, how can Cuts Digital's tools, like GSD Cast, GSD Quest, how can they help with these challenges?(Jamie Symon)

Yeah, I think how... How we're approaching this is not just a tool that helps something, but how do we use this tool to then connect throughout the entire system? So I think if we look back over the last 10 years or so where we've seen that digitalization start with things like CAD, 3D coming into effect, people using PLM systems to start storing data and understanding the entire lifecycle of a product, this led to a more efficient process in the early stages of a garment's life cycle. So in design and in 3D sampling, it was more about speeding up that process, creating fewer physical samples and obviously therefore becoming more sustainable and more efficient, getting to market quicker, but also about understanding that you can create more iterations of a garment, understand sizing better and have fewer returns. So how does that impact later on down the line? And now I think what we're doing is we're moving to a stage of concentrating more on that supply chain, on the delivery and reacting more quickly to trends and understanding how we can more quickly react throughout that kind of manufacturing process as well.(Jamie Symon)

And to do this, brands have to be able to react quickly whilst dealing with a constant change. in what's going on. As I've mentioned before, and as Florian mentioned, this is going to be probably a lot of the theme of this is kind of improving sustainability, improving efficiency whilst understanding we live in a very challenging world. In order to do this, brands need to be able to, brands and manufacturers actually, need to be able to plan production better. Florian mentioned about forecasting and having better utilisation of energy consumption and those down times and those boom times in understanding how do we actually have those garments flow through a factory. And what we're doing at Code Digital really is having tools that apply to that.(Jamie Symon)

So things like a fast reactor plan, our planning tool, which is enabling factories to plan their production more efficiently. Fast React Fabric, which is enabling us to really make as best use as possible out of the fabric that we have so that we are, you know, incurring as little waste as we can. And then, of course, and we'll mention it a few times today, is GSD. GSD costs, you know, with its new AI functionality, GSD Quest, it's enabling manufacturers and brands to quickly and accurately predict cost. It's enabling brands to understand cost at an early stage, but it's also is now adding a different layer where we're kind of moving further up that value chain. Brands are now understanding the implication of cost in its design phase.(Jamie Symon)

So whereas in the past, understanding the cost of a garment through its bill of labor, its material utilization, its thread consumption, that was kind of after the fact. Let's create a sample. Let's talk about manufacturing partners and understand the cost of this garment and then work out how much we're going to pay them. Now what we're able to do is we're speeding up that costing process, is make those decisions earlier on. If I add a pocket to this garment, what is the cost implication further on down the line when I actually output this to a manufacturer?(Jamie Symon)

And really that's what we at Copes Digital are trying to do. We are enabling customers to make more informed decisions throughout that entire process as early as possible. So there are no surprises and we're not calculating these things after the fact.(Madelaine Thomas)

Thank you, Jamie. And talking of AI, if we look at that more specifically now with Euflorian, how can AI help the industry to step further towards more sustainable production?(Florian Pohlmeyer)

I think one important aspect there is that the AI itself will not help anyone in the industry. It's the right usage of this tool, AI, because AI is not not more than a tool. Yeah, we have a lot of examples. So for example, when we talk about material efficiency, so analyzing fiber blends, for example, we use in the textile manufacturing or analyzing process parameters, quality data in real time to use this data and insights we get from the process for example for optimizing energy consumption or profitability of the production. So we had a research project, for example, in the last years, where we developed AI agents for the nonvolence industry, part of the textile industry, where, yeah, in the end, the agent was able to about the process by itself and to control the process in the end and there we saw in the results that the combination of the experienced operators of these machines and the AI agent were able to optimize the production process when we talk about profitability.(Florian Pohlmeyer)

So this was a very good example where we saw that AI, not only AI as a tool can help us, but the combination of the operators we have and the technologies will be beneficial in the next years. Another aspect will be like circular economy, circularity. So we need artificial intelligence and we see a lot of projects in this area. When we talk, for example, about sorting textile waste for being able to actually recycle the waste. So yeah, these were just a few examples. about digital transformation in the textile industry.(Florian Pohlmeyer)

But I think the most important aspect to mention here is that AI doesn't make the production sustainable by itself. It's all about the usage of those technologies and the right use cases and in the right way.(Speaker)

Exactly.(Madelaine Thomas)

And I guess it's education that comes with that for the industry as well. But there's some really exciting, if not a little bit scary examples in some ways. How far off do you think we are having AI agents kind of within the manufacturing facilities?(Florian Pohlmeyer)

Yeah, this brings us to a problem. So right now we have those very promising results and research, but we see on the other hand that a big part of the industry is not ready for implementing those AI agents. So because again, I mentioned it earlier, we need better data quality, because the agent is just as good as the quality of the data. So I think this is the most important aspect when we talk about artificial intelligence. Companies should start with building up their infrastructures for with a focus on data quality, not with a focus on starting the huge and shiny AI projects. It's more about getting the data in the right way, because then when you did this work, which is a lot, you can gather the right insights out of the data.(Madelaine Thomas)

That's really interesting. Thank you Florian and Jamie to come to you on that point and data and how courts is driving industry to be more sustainable and efficient in its production.(Jamie Symon)

I think, just to kind of clarify on that point of AI, and it being a tool, and not a tool that's going to kind of come and take all of our jobs and do everything right now. I think, you know, I 100 % agree, Florian. Yeah, AI is this word that we're hearing at the moment and we think, you know, It's an artificial intelligence that is going to come and just do what we ask it to do. You know, that is not the case. It is built on large language models that are only as good as the information that is in there. Okay, it's improving every day.(Jamie Symon)

but unless you have the data it's built on, not only good data, but also not the bad data, because it takes both into account, your tool is only as good as the data, and we see that with GSD, you know, GSD is It is the standard when it comes to time and cost calculation in the industry. Everybody has heard of the program. The majority of the people I'm sure watching have used it or seen it at some point. One of the reasons our new AI tool is so good is because it's drawing upon the data that is already in our system. And I think going back to the question as well, because I went off on a slight tangent there. What we're seeing is there's time lost in exchanging information manually throughout the entire system.(Jamie Symon)

So investing in a tool that is going to connect all of that information is really the way forward. That's what I'm seeing is how do we use the information we already have and not have to replicate it? How can we make sure that if we are creating a cost here, we can understand that cost at any stage? If we are connecting the supply chain, we're not losing information because someone sent a letter, someone sent a Teams message, and someone sent a WhatsApp. How do we make sure that there is an ecosystem that takes all of this into account? And really, the only way we can do this is through AI integration.(Jamie Symon)

How do we stand at the moment? We're talking about things like CAD models and physical prototypes. How are we shipping? Where are the tech packs? Is our cost in Excel or is it in GSD? How are we planning our production?(Jamie Symon)

What information is syncing with our ERP system and our PLM system? What marker files are we using? What is the stitch length within a product and what thread type is that and how are we choosing that thread. These are all individual processes currently and what we really need to do is start concentrating on how we connect that process. And the advantages to this, I think, are fairly obvious in terms of efficiency gains. But also, if these systems are connected, we can make use of that information, as I mentioned earlier, further up and down that chain.(Jamie Symon)

So tools like GSD are now connecting at the design level. phase, potentially, because using AI, something that used to take hours is now taking seconds or minutes, depending on the complexity of a garment, enables you to make better, more efficient, more informed decisions. But it also enables you to improve your process by measuring it. So one of the things that I talk about a lot when we're talking about GSD, GSD has a scientific approach to understanding the bill of labor within a garment, only by measuring that scientific approach and then measuring what you're actually getting on the shop floor, can you then understand where you're losing out, where you're not having those efficiency gains. I think measuring that, connecting the system and then making those step -by -step improvements to become more efficient is the way that we concentrate on those sustainability gains and becoming more efficient generally.(Madelaine Thomas)

Thank you, Jamie. It's really, I think it's really good to put some kind of real life technology to the theory we discussed so much. So Florian, we'll come back to you now, because I want to kind of zoom out a little bit and kind of take a broader look. So within both digital and analog manufacturing environments, AI is proliferating at a rapid rate, as we've discussed. Governments like Thailand have made it central to their digital transformations. transformation strategies in manufacturing and China and the US are kind of vying for the position of innovation leader in this space as well.(Madelaine Thomas)

And then there's also increasing demand for AI driven robotics in all areas of manufacturing. So how is AI accelerating the need for digital infrastructure and how are government initiatives supporting this implementation?(Florian Pohlmeyer)

I would say that this current AI transformation changes like the hierarchy of needs in manufacturing. So once companies want to start with using AI, so for example, for optimization, for prediction, for robotics, and so on, they will immediately face this structural requirement, which is about reliable, in best case standardized and interoperable digital infrastructure. So we are at this data quality aspect again. So because those systems need this high quality data, which is stable, cyber security is another very important aspect. The information, for example, about products needs to be machine readable. We need a structured governance about how to work with the data and so on.(Florian Pohlmeyer)

But when we do not have this foundation, I think there's different tools in this area of artificial intelligence will remain isolated and it's very hard to scale them across plants or supply chains and so on. Yeah, so I think the more AI is adopted, the more pressure is on this infrastructure side with this main goal of data quality and its many different dimensions. And I think those initiatives by governments, for example, can play a critical enabling role. So for example, in Europe, we see programs like GAIA -X or some other German initiatives, for example, to build secure data spaces. So the digital product passport is a very good example of this.(Florian Pohlmeyer)

So we see those initiatives which can help the industry to shift towards those infrastructural components we need for really adopting artificial intelligence. Yeah. And then another very important aspect, we have, for example, some projects here in Germany that we need to reduce the entry barriers for companies. So, especially when we talk about smaller companies, for example, and this is again about like easy to understand frameworks, standardization, a shared infrastructure and so on. So, we need to get more specific and come to the real necessary point in all those buzzwords we hear when we talk about artificial intelligence. And yeah, I think those initiatives and infrastructure can help to the companies to just start, for example, with the first use case, because in my opinion, this the most important aspect to just start and learn with adopting, for example, those first easy-to-understand use cases.(Madelaine Thomas)

Thank you, Florian. And Jamie, to come to you, why is it now that brands are taking this crucial role in driving digitalization within their supply chains and what benefits are there to this?(Jamie Symon)

Yeah, I think by using those AI tools and driving dig digitalization, I think, you know, what we used to see was that was like a competitive edge. And that was the thing that brands needed to do to try and get ahead. And I think what you're seeing now is it is a necessity, unless you have those tools, you will very quickly fall behind. What we are seeing is that jobs are becoming more AI centric. And whilst that is, you know, some scary for some, what it's actually doing is enabling those individual contributors to become more more effective in their role, but it also enables them to become a bit more analytical and allows them to concentrate on those constant improvements rather than just actually fulfilling the role itself. I think scale and low -cost manufacturing are no longer enough.(Jamie Symon)

And I think adding these tools in terms of that digitalization, digital transformation, sorry, and having the digital twin online where you can do everything virtually before you do it physically, really is the only way that we're kind of going to proceed. So, you know, the new technology and improved productivity really are those differentiators. I think this is how we're going to enable growth.(Madelaine Thomas)

Thank you, Jamie. I want to kind of just stop the discussion there, if that's okay for now, because we have lots of audience questions to get through. So we do have lots, but there are the We can still make time for some others. So if you do have some questions, do feel free to send those in and we'll try to get to them. And if we don't get to them all, then I'm sure Jamie and the team will answer them via email or something afterwards. So we'll start off with the first one.(Madelaine Thomas)

Can you give some real -world examples of what you mean by digital transformation? I mean, throughout the discussion, we've heard a few, but I think it'll be good to reiterate this for this delegate. Who wants to go with that? Florian, do you want to go with one? And then maybe, Jamie, you can give another example related to digital, yeah?(Florian Pohlmeyer)

Yeah. It's a very good question because this shows the problem with the buzzwords when we talk about digitalization and artificial intelligence. So I can give another example of one of our projects we are currently working on. It's a project in the paper industry, but it will be quite similar in the textile industry. There in the paper industry, this energy usage is very, very high. So energy costs are a very, very big problem in the paper industry.(Florian Pohlmeyer)

And there we build a solution for transparency of energy consumptions in different areas of the production machine for the paper. And yeah, paper machines are very, very big, have many different aspects. And right now, it's not possible to say where we need which amount of energy in the aspects of the process. And therefore, we build up like a interoperable infrastructure for getting more transparency about the energy consumption in the manufacturing process for paper. And now we are able to use this tool, for example, for optimization strategies. So we can(Florian Pohlmeyer)

or we can use the data to simulate when we change one thing in the process, which result we will gain in terms of energy. Yeah, I think this is a very good example right now because, yeah, This is also a good example where we work closely together with the industry. So we have a few companies of the paper industry in this project and directly address the needs of the operators, of the project engineers and so on.(Madelaine Thomas)

Thank you, Florian. And Jamie, we'll just come to you for some insight on the court side, an example of digital transformation, please.(Jamie Symon)

Yeah, absolutely. I think this is a big, big question. I think we haven't got enough time. days this week to kind of answer it. I'll try and give some examples. I mean, you know, the obvious one that I've spoken about a couple times today is this GSD cost.(Jamie Symon)

So GSD cost, really understanding cost at an early stage prior to manufacturing something. So, you know, in the past, what you would do you would manually create a time and work study for that bit of labour, so you'd stand next to somebody at a sewing machine and you'd figure out how long does it take to sew that seam, or not even that, grab a piece, grab a piece, put it together, sew it, and how long does that take. You have to do that physically. You're utilizing resource that you don't need to use. That person that's doing that test is then not actually in the manufacturing environment. You're using materials that you potentially aren't going to go into waste because it's just a test.(Jamie Symon)

What we're doing in GSD Costa is enabling you to do that virtually. But not only doing that virtually, but also doing that with a science -backed procedure that allows you to then compare the real world of what are you getting and what are my efficiencies on the shop floor to what should we be getting and what could we be getting.(Speaker)

if we work on those efficiencies.(Jamie Symon)

If I'm going to step slightly outside of the codes digital realm for a second, there's also things like When you're selecting thread within the Coats thread world, color management and understanding the selection of that thread is a huge task. And so we now have partnerships with companies like DMIX, which is a color management tool enabling you to have that process digitized and selected from that beginning. So you're not actually having to buy thread and hold them next to each other and compare.(Speaker)

to compare colors.(Jamie Symon)

There's also a German company called Bizu, which is digitalizing materials so that when you are creating CAD designs, you can actually have the exact drape and fabric properties so that you're creating those 3D samples very early on. And then again, going back to Codes Digital, the tools we have like Fast React Plan, which I think the obvious benefits of planning those production cycles planning your lines, understanding what you should be getting, understanding what you are getting, and then comparing two to kind of increase those efficiencies. And I think all of these digitization methods are improving the process, they're speeding it up, but they're also enabling us to have less waste.(Madelaine Thomas)

Thanks, Jamie. Just on that Fast React, actually, we do have a question on that. Systems like Fast React have already embedded AI tools to better analyze planning options, or do they still rely on rules described for the simulation?(Jamie Symon)

Watch this space, is what I would say. We are constantly improving our tools. We have a lot of plans when it comes to the use of AI within our systems. Now, the benefits of this, and Florian alluded to this earlier, and I reiterated, we have some industry -leading tools that have the data backed up. By then using AI on top of that, you're then using the tool, but using the expertise and the knowledge built within a system that's been around for 20, 30 years and improved constantly over that time.(Jamie Symon)

So you're using those systems in the background, and the AI is making decisions, but based on good data. And I think, yeah, again, watch this space, you know, we have our roadmaps are relatively public, we do, we do, we do show those. But AI is a tool that we are constantly investing and constantly using within our systems.(Madelaine Thomas)

Just another on the technology Jamie, is the GSD solution currently integrated with any advanced planning and scheduling platforms and does it provide standard APIs or other interfaces to connect with external systems?(Jamie Symon)

Yeah, very good question and something that we come up against often. Yes, we have great API tools that allow us to connect with systems such as PLM, ERP, and planning tools. We currently create those manually. We have a lot of those already embedded within the system. But if there's something that we haven't come across, we do have those tools to create the links, yeah.(Madelaine Thomas)

Thank you. And Florian, we'll come to you now because we have a kind of a more education based question and it's actually something that we've discussed at length in the past. Do you think universities should address both the global level value chain and the detailed level execution operations on the shop floor, working directly with companies in the field and developing solutions that fully consider their human and financial constraints?(Florian Pohlmeyer)

Yeah, sure. So in my opinion, universities absolutely need to work on both of those levels, so this global system level and like the everyday operational level on the shop floor. Because if we only analyze the bigger picture, so the value chain from a distance, we tend to produce theories, for example, that won't survive contact with the real factories. And On the other side, if we only optimize individual operations, we will miss the structural forces in the value chain. I think both sides are quite important.(Florian Pohlmeyer)

In my opinion, let's say our responsibility is to connect these two worlds. directly work inside the factories, for example, understanding the human needs, understanding the financial constraints, building lightweight solutions, which are, for example, affordable, adoptable. Yeah, and proven that they, they work. Yeah, in the in the real world, and not just designed for ideal conditions that do not exist in reality. for our aspect here at RWTH, this is one of our most important ways to do projects. So in most of our projects, we directly work with the companies.(Florian Pohlmeyer)

So for example, we start with the use case development where we directly talk to the people in the companies to get this real world pictures. Yeah, so I think, universities must operate like on the one side. as this system architect so with the broader picture and on this operational level at the same time.(Madelaine Thomas)

Thanks Florian and Jamie we have an interesting question here on the industry and it being consumer facing. So the industry seems focused on consumer facing AI integration. What kind of data is needed to integrate AI solutions into tier two and tier three in textiles? The impact savings are more possible here, but how do we unlock this?(Jamie Symon)

Yeah, that is a very good question, a very interesting question. I think we start talking about tier one and we're talking about planning production and that interface with the brand. When we start talking about tier two, we start to take that step back and understand what goes into what those tier ones need. So it's the communication between the tier two and the tier one. And so we start to look at things like individual marker creation, thread selection, you know, material selection and this kind of thing. And I think those tools have, you know, we have tools in those, we have them and have been in there for a while.(Jamie Symon)

I think you're probably right. I don't think the AI solutions are concentrating on them at the moment. However, I think if you start to look at, you know, the manufacturing environment in the tier two, the solutions that are there, you know, need to be less connected, I would argue. But certainly, it's got to go down that route eventually.(Speaker)

Thanks.(Madelaine Thomas)

And a question here more on the GSD side. It's a long question, so I'll paraphrase it. But GSD has been widely used for decades. How has the solution evolved to incorporate a broader range? of processes and integrate with other systems, etc.? And does your current solution offer new models?(Speaker)

Yes.(Jamie Symon)

So yes, you're right, GSD has been around for a while. We have our core technology that involves those 39 motion codes that make up features and styles and operations. Now, the power of GSD and where we see it best utilized is when a brand or a manufacturer is using the product, builds their own libraries. So how are we changing it? How are we evolving it? We are constantly investing in our libraries.(Jamie Symon)

We have our own standardized library that we ship with the product, but everybody has their own processes. you go to a big sports manufacturer that probably has some proprietary type processes that are involved in their manufacturing, what we are doing is enabling those customers to build their own libraries. So as technology improves, as technology differentiates, customers have to keep on top of those libraries to make sure that what they're using and what they're forecasting is accurate. And so, again, we are helping do that. We are improving our own library as well as helping customers improve their own personalized libraries. And again, going back to Florian's point about data and AI, the system is only as good as the data that you're using.(Jamie Symon)

And if you have a sewing machine that's 100 % faster than what you bought last year, then that has to come into effect. You have to then build that into your process. You have to then update your libraries. And the customers that are best utilizing our software, as I mentioned, are those that are keeping on top of those libraries, but also using that to understand where the efficiencies are. If you have different processes, you can then benchmark that against what you currently have and understand what are the cost implications of investing in that new capital acquisition Yeah, no, again, to answer that in a short way, yes, we are updating those libraries.(Jamie Symon)

Yes, we are investing in the product. That's shown with, obviously, the AI tool, but also with all the other feature improvements that we have introduced over the last couple of years.(Madelaine Thomas)

Thanks, Jamie. And another question here, and this might be one for more of a follow -up, because it might be quite specific, but how would you go about finding the right system to capture design to final production sign -off? We not only need data collection for product and reporting, we ideally want to move to a fully integrated system to replace manual trackers and workbooks. Finding an off -the -shelf solution seems to be impossible. So, Jim, if you have thoughts on that, and Florian, if you have any ideas on that as well.(Jamie Symon)

Again, there's lots of very in -depth questions that I don't think we have enough time to answer them all. However, I think something that we try and put across, certainly with GSD, and I think it applies to any design tool as well, is that a design tool is a tool. and it's only a tool. And the tool is only as good as the process that you put in place to actually use that tool. So one of the things that we like to concentrate on is understanding the customer's needs, understanding what they're trying to do, not just saying, here's a tool, you can now use it, but actually sitting with them and taking them through individual case studies to say, this is how we do this. So understanding as well as a tool, it is a process change and that there is a mindset change in using that tool.(Madelaine Thomas)

Yeah, I mean, there's more I could go into, but I think probably one to follow up. So we are running out of time. We still have loads of questions to go through. So you might be busy doing follow ups, Jamie, I'm afraid. But we'll just finish on one interesting point here. Digitalization started more than four decades ago with the introduction of microcontrollers and(Madelaine Thomas)

MES systems. So why is the textile sector still lagging behind in this area? Florian, we'll have some parting words from you on this and then Jamie will go to you for a final answer on this as well.(Florian Pohlmeyer)

It's right. Digitalization started decades ago. But I think tech cells did not fall behind because of lack of technology. So it's more like they maybe fell behind because of the structure of the industry. So the value chain is extremely fragmented, cost -driven, globally distributed, margins are thin, we have this fast fashion, for example, as a trend. And therefore, I think that digitalization was always seen more like a cost, not not a capability you should have as a company.(Florian Pohlmeyer)

And it was the main focus was always about optimizing speed, optimizing price. And for example, transparency or circularity were not that important in those decades. But I see right now we we we see Yeah, I would call it a structural shift, because we see those demands and challenges right now, which will force transparency and data integration. So maybe by regulation, but also by this cost aspect, for example. So right now, I think that the industry is realizing that digitalization is not that nice to have. It's more like this(Florian Pohlmeyer)

yeah, you need it to be able to come up with all these challenges we see.(Madelaine Thomas)

Brilliant. Thank you, Florian. And Jamie, a final word from you on this?(Jamie Symon)

Yeah, I think to bring it back full circle to probably the very first thing I said, you know, I started my career in automotive and aerospace. And what we were doing there is we were kind of improving and introducing digital transformation because the industry was a bit more specialized. The cost of material and the cost of production was more expensive. And so that digital transformation question was a little bit easier to answer. 20 years later, I'm now doing the same in the apparel space. And I think that's what happened.(Jamie Symon)

Materials have become more expensive. It's not so much a we'll just find it somewhere cheaper. That's not the answer anymore. And the scale and cost is is of such a scale now that the digital transformation has to be the next step.(Madelaine Thomas)

Thank you, Jamie. And that's a really nice point to finish on. So thank you once again. We have gone on quite a bit longer than anticipated. but it's our audience's fault for all their questions that were very interesting, and also your discussion points as well. So thank you, Florian and Jamie, for your most valuable insights.(Madelaine Thomas)

And thanks again, everybody, for all your questions. Jamie and the team, no doubt, will be in touch if we didn't get round to answering. There was a lot of questions, so that we, unfortunately, didn't have time to answer. But you'll be able to have a more personalized discussion one -on -one. So we've discussed some really important topics including the new exciting technologies that are out there for improving productivity and how we can be more efficient in connecting those dots in manufacturing. We've also looked at how digital transformation(Madelaine Thomas)

AI are now a structural necessity, a foundation, as Florian so eloquently said, and how AI and digital transformation are no longer a competitive edge, but that necessity, as we said, for efficiency, sustainability, and increasing margins, et cetera, many of the benefits that we discussed today. So for any further questions or help on digitalization, AI empowerment, then please use the QR code provided on the screen that Jamie will share now. Thanks for doing that for us, Jamie. Great. We see it.(Speaker)

Perfect.(Madelaine Thomas)

So yeah, do use that QR code if you want to get in touch with the COATS digital team. And when the webinar ends, a pop -up will appear for the GSD Quest website. Please just press Continue if you'd like to go through to there to access the website. So thank you once again, everybody, for attending. I hope you found this as insightful as I have. And thank you, Jamie and Florian, for all your insights as well.(Speaker)

Thanks very much, both.(Jamie Symon)

Great to connect.(Florian Pohlmeyer)

Thank you.(Madelaine Thomas)

No worries. See you again next time, everyone.