-

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

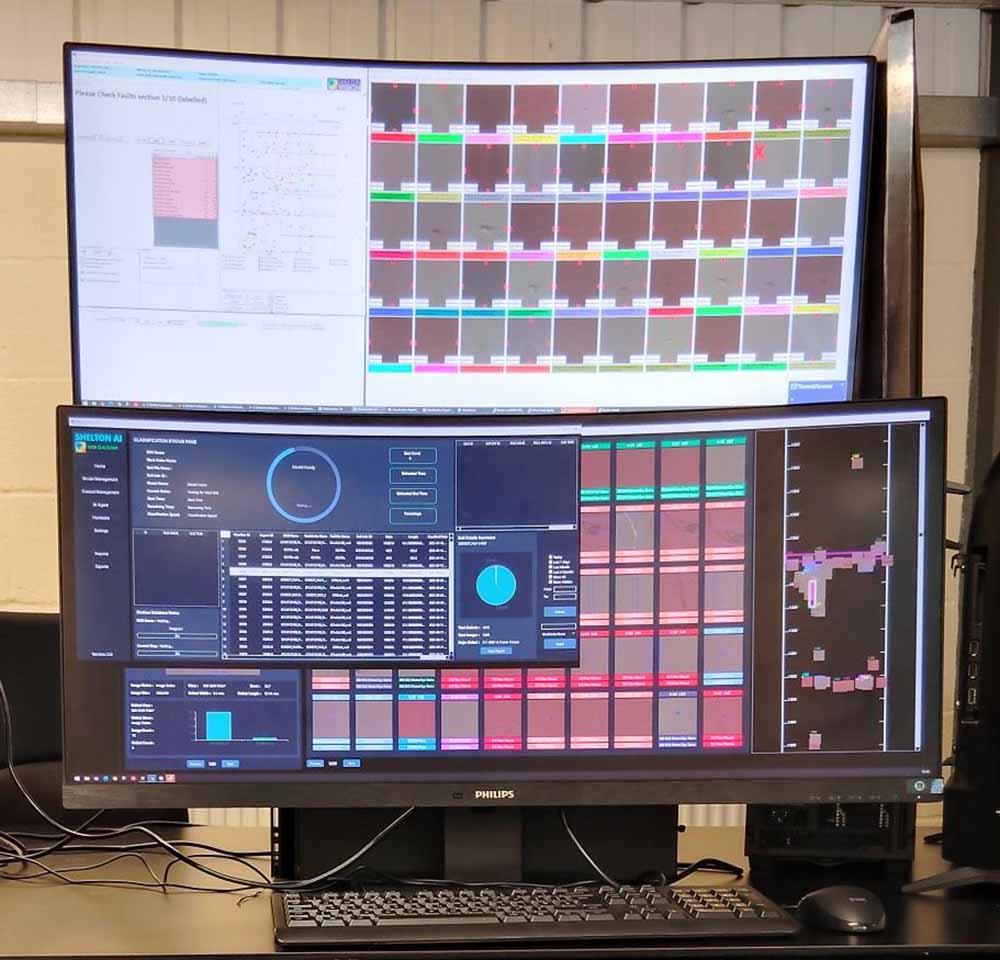

Machine learning and AI are now entering the field of textile technology and at this year’s ITMA Asia + CITME exhibition from 28-31 October in Singapore, UK-based Shelton Vision will demonstrate how these advanced new disciplines are informing its latest machine vision technology.

The company is one of a 20-strong delegation of members of the British Textile Machinery Association (BTMA) who will be present at the Singapore exhibition, showcasing advances in technologies for new high-performance fibres and fabrics, as well as testing, instrumentation and control in processing.

The ability to detect and classify even the tiniest faults in both plain or fully patterned fabrics which are moving at industrial speeds is one such breakthrough.

In Singapore, Shelton Vision will demonstrate its latest WebSpector machine vision high-speed inspection technology incorporating machine learning (ML) to provide a defect detection level of above 98% and Deep Learning AI to provide up to 100% defect classification and grading accuracy.

Shelton will also demonstrate a stand-alone AI Classifier in multiple applications used within the Shelton suite of vision system components. This can be adapted for use with existing third-party inspection systems that do not have defect classification (naming) or grading functionality. Thus, eliminating subjective manual decisions in day-to-day operation and vastly increasing the efficiency and throughput of the album review process.

Shelton Vision CEO, Mark Shelton, explains: “At the show, we will focus on the output data from our vision systems and how this can generate benefit for the whole value chain, including brand, by providing to everyone a reliable source of fabric quality data immediately the fabric is inspected. This results in reduced lead times, reduced fabric waste and increased productivity and efficiency and our patterned fabric inspection system is now already entering new markets such as outdoor upholstery and one piece woven (OPW) airbags, even as the original market of camouflage printing continues to grow.”

The tactility challenge

Meanwhile, the tactile sensation experienced when touching and manipulating fabric is a critical aspect of textile evaluation. However, to date it’s been very subjective and one of the biggest challenges faced by designers and manufacturers is in describing and sharing information about fabric aesthetics before manufacturing, or without the costly and time-consuming process of transporting physical samples.

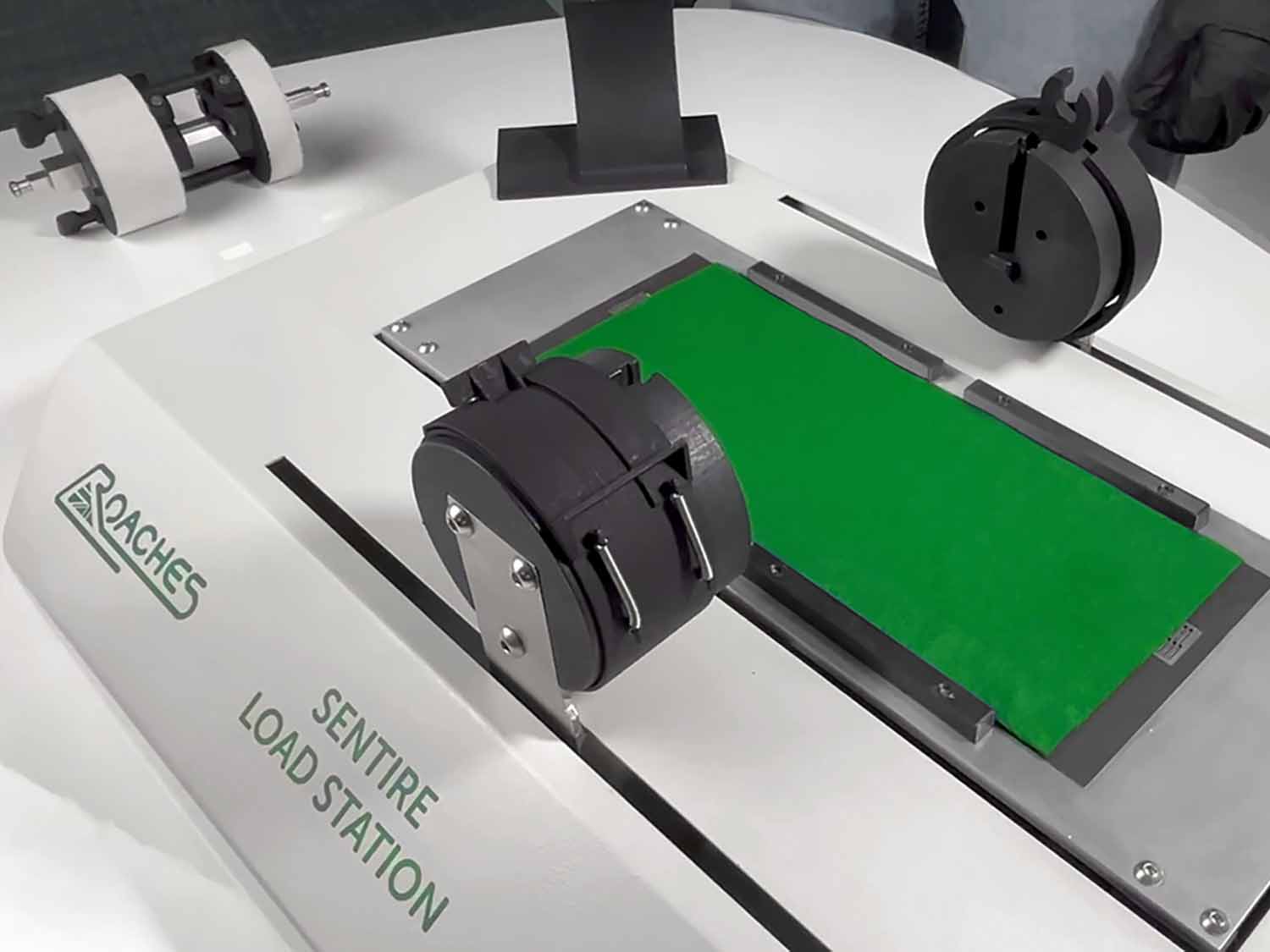

These limitations are being overcome with the new Sentire fabric handle tester, just launched by Roaches International.

Sean O’Neill, Roaches International managing director, says: “No two people will describe how a fabric feels in the same way and the lack of a common language to describe fabric tactility poses communication challenges across the complex global fashion and textile supply chain. How do you objectively measure qualities like softness, smoothness, drape and stiffness?”. The answer is with the new Sentire.

Haptic spatial system

Roaches worked with specialists at the University of Leeds, UK to develop the new finished fabric evaluation system which defines the tactile properties of fabrics via a haptic spatial system – similar, for example, to the way colour charts are digitally defined for colour palettes, or tog values rate warmth.

Fabric samples are placed into the Sentire to run a series of tests which generate quantitative fabric tactile property data akin to a fingerprint for the fabric, which can then be compared against other samples and communicated digitally to partners in different locations.

“This technology has the potential to impact the supply chain in a similar way to the spectrophotometer for the communication of colour,” says O’Neill. “We have had a fantastic initial response to the Sentire and its possibilities are huge. Not only can it be used to compare textile tactility globally, but we are also seeing interest from online retailers who want to accurately display the way a particular fabric drapes on the body.”

Pushing the boundaries

“BTMA companies continue to push the boundaries of what’s possible and some of the most recent innovations by our member companies are really going beyond what has previously been possible,” says BTMA CEO, Jason Kent. “This year has been extremely productive for our members so far and there will be much to talk about in Singapore.”

BTMA companies taking part in ITMA Asia + CITME 2025 are:

- Airbond: stand A202, Hall 2

- Autofoam: stand B309, Hall 7

- AVA CAD/Cam: stand C210, Hall 6

- Cygnet Texkimp: stand B493, Hall 8

- Fibre Extrusion Technology: stand B306, Hall 4

- James Heal: stand B306, Hall 3

- MCL: stand A203, Hall 5

- Roaches: stand A112, Hall 2

- Saurer Fibrevision: stand C301c, Hall 3

- SDC Enterprises: stand B107, Hall 8

- Sellers: stand B207, Hall 7

- Shelton Vision: stand B308, Hall 7

- Slack & Parr: stand D305, Hall 4

- Society of Dyers and Colourists: stand B203, Hall 3

- Strayfield: stand B509, Hall 7

- Tatham: stand D205, Hall 2

- The Textile Institute: stand B105, Hall 8

- Verivide: stand B201, Hall 3

- Vickers Oils: stand B102, Hall 5

- Wira Instrumentation: stand A108, Hall 3

Have your say. Join the conversation and follow us on LinkedIn