-

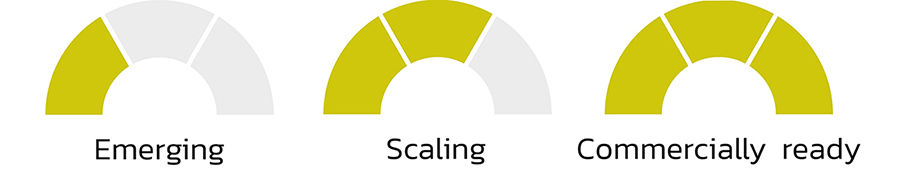

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

Sponsored by Outlast Technologies

Climate regulating material specialist, Outlast Technologies, discusses its high-performance insulation, Aersulate and how it has the potential to change the game for designers in the outdoor and workwear space.

In the world of thermal protection, aerogel has always been something of a legend. With an air content of up to 99.8% and the lowest thermal conductivity of any solid, it has shielded NASA spacecraft, Mars rovers and astronauts from extremes that would destroy most materials. Yet, in the 90 years since its invention, one of the key challenges has been that aerogel’s brittle, powder-like structure makes it extremely difficult to integrate into flexible textiles at high concentrations without compromising handling or durability.

That changed when Outlast Technologies developed a patent-pending process to permanently embed high concentrations of aerogel into fabric structures without affecting softness, flexibility or processability. The result is Aersulate®, a high-performance insulation delivering lab-proven results at an astonishing 1–2mm thickness, the company says.

Turning thickness into possibilities

"Independent testing confirms a significantly increase in thermal resistance compared to identical fabrics without Aersulate," explains Volker Schuster, head of R&D at Outlast Technologies.

In EN ISO 11092 measurements, a 1.1mm nonwoven with Aersulate reached 0.08 m²K/W versus 0.045 m²K/W for the same nonwoven without it. This marks a 78% improvement without adding a single extra millimetre to the fabric.

According to Outlast Technologies, for product designers, this shift is critical: performance no longer depends on bulk. It becomes possible to create slim silhouettes with the same, if not better, thermal protection than thick conventional layers.

Performance in real-world conditions

Conventional insulation materials such as wadding or PU foam often lose a substantial portion of their effectiveness when compressed for example, under the weight of the wearer or when exposed to moisture from rain, snow or perspiration. In comparative hot plate tests (90°C, 0.5 bar pressure), these materials quickly allowed heat to pass through, reducing their protective capability, says Outlast Technologies.

Schuster explains: "Under pressure and moisture, performance loss is negligible. This is a key advantage over conventional materials.”

With Aersulate, the aerogel structure remains intact even under sustained compression or in humid conditions. The trapped air pockets that provide insulation do not collapse or migrate, meaning thermal resistance stays consistently high. This reliability enables product designs that previously suffered unacceptable performance loss in demanding environments.

Exceeding safety benchmarks

Protective clothing is a proving ground where materials must perform under extreme, life-threatening conditions. Aersulate has been tested according to EN ISO standards for flame, radiant heat, convective heat and contact heat - and the results are remarkable:

- Radiant heat: +54% time buffer before critical temperature

- Contact heat: 2.5× longer resistance

- Convective heat: +58% escape time margin

"In practice, that means a firefighter gains more than double the safe escape time in high-heat scenarios," notes Schuster.

Design potential beyond safety

As it delivers full performance at only 1–2mm thickness (comparable to the thickness of a credit card) Aersulate gives designers a level of freedom rarely seen in high-performance insulation. This slim profile allows for sleek, lightweight products without sacrificing protection or thermal efficiency.

- Outdoor jackets reinforced in high-stress areas such as shoulders and elbows

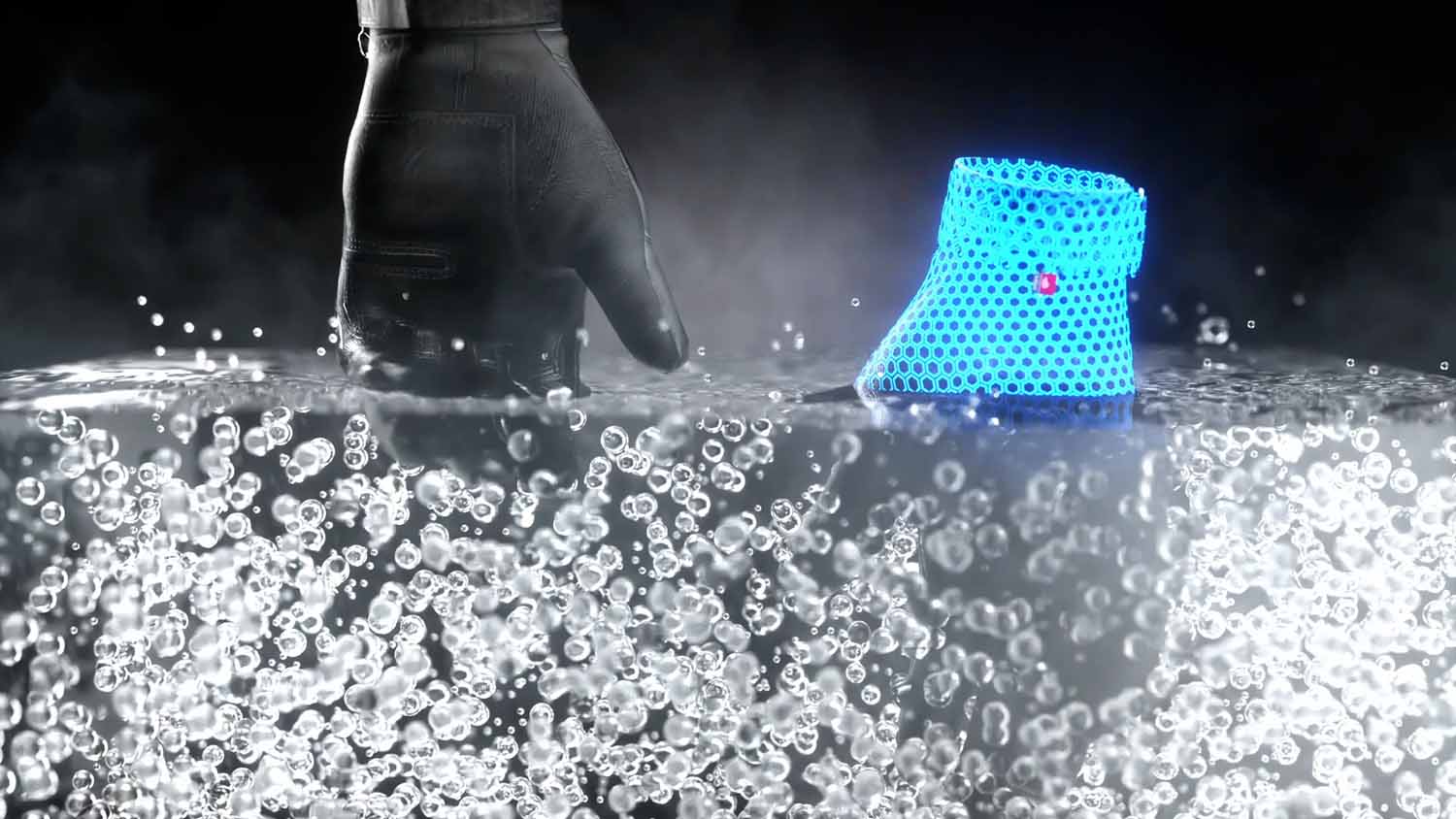

- Gloves thin enough for dexterity yet resistant to boiling water immersion

- Footwear with thermal stability under load and in wet conditions

- Equipment pouches that keep electronics operational in extreme cold or heat

This ability to combine minimal volume with maximum insulation opens product categories that were previously impossible or impractical to insulate. Thus, enabling performance, comfort and aesthetics to coexist in a single design.

From quartz to high performance: The material science behind Aersulate

Aersulate’s exceptional performance is rooted in its natural origin: aerogel is derived from quartz, the base material of sand. “It’s safe, stable, non-toxic and produced entirely in Germany under strict environmental and safety standards,” says Schuster. This inherent material stability ensures long-term performance reliability, while its quartz-based compo-sition delivers tangible sustainability gains for brands with defined environmental responsi-bility goals.

A new tool for innovation-driven brands

“We have taken a material from space equipment and made it accessible for everyday and technical applications,” Schuster summarises. “The data speaks for itself, but the real value for brands lies in the opportunity to innovate in areas where this was previously not possible.”

From high-risk occupational safety to high-performance consumer products, Aersulate is enabling a new generation of designs where space, weight and environmental conditions are no longer limits but opportunities.

Have your say. Join the conversation and follow us on LinkedIn