Sponsored by Brother

The direct-to-film (DTF) printing market has grown quickly over the last five years, disrupting the garment decoration market. The technology offers versatility, vibrant results and new creative possibilities for businesses of all sizes. Yet behind the excitement, many print professionals have learned a hard lesson: not all DTF printers are built to perform.

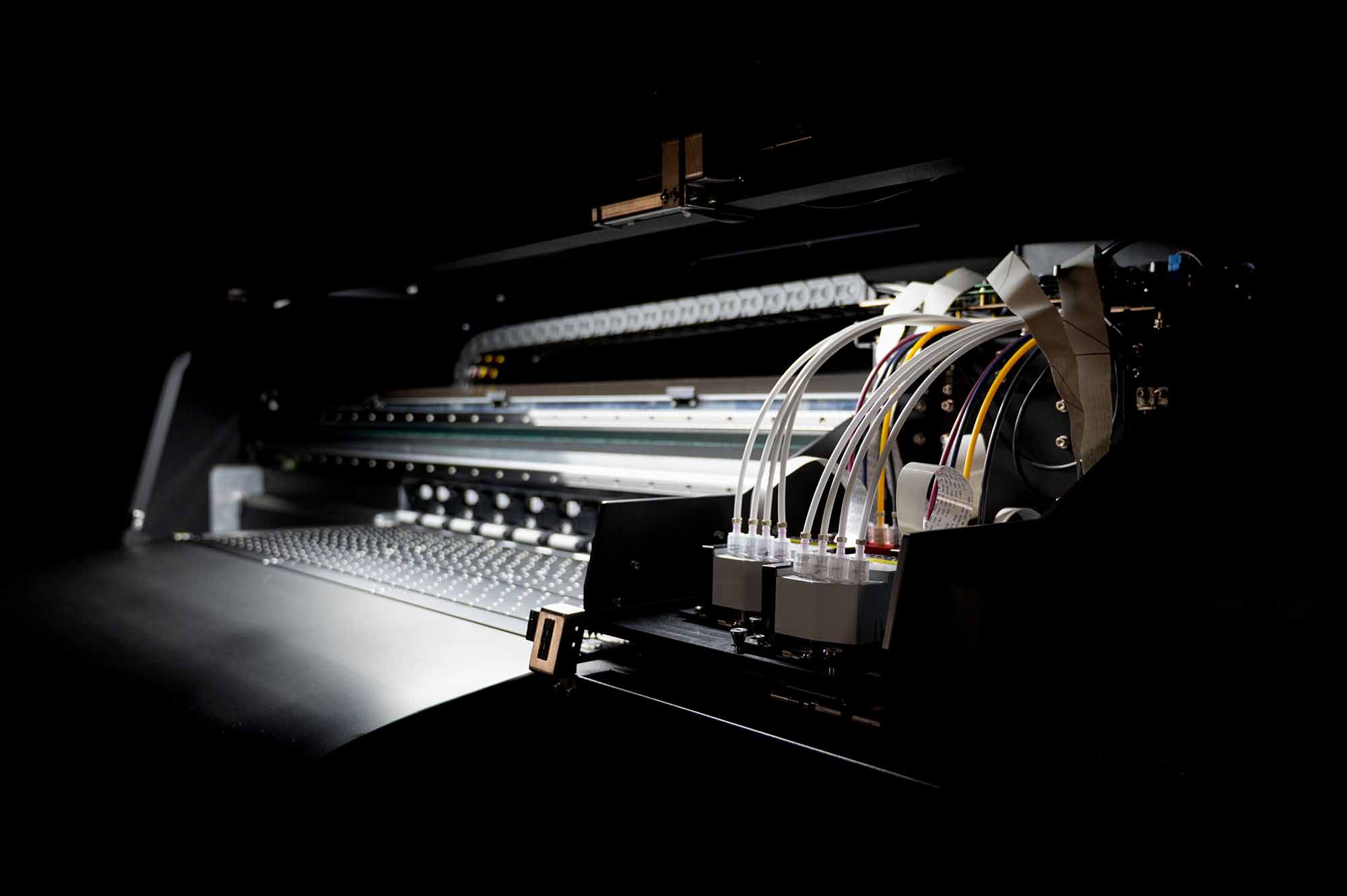

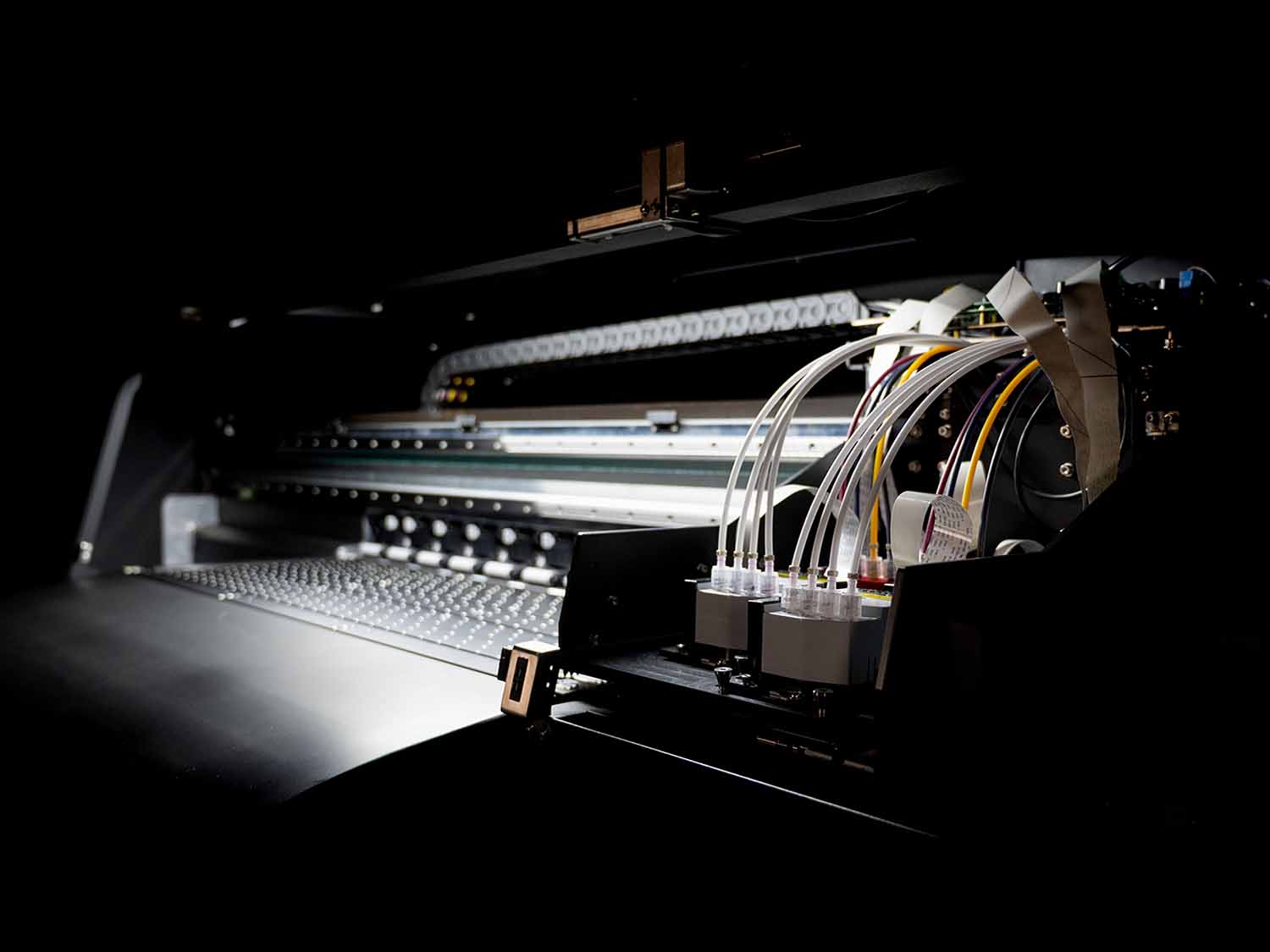

Brother has launched DTRX, a new DTF printer that promises to cope with the realities of daily production and overcome the challenges experienced by cheaper DTF solutions, such as material waste, uneven colour reproduction, clogged print heads, inaccurate film feeding and poor temperature control, resulting in unpredictable output and missed deadlines.

WTiN has interviewed Brother EMEA’s marketing manager, Folker Stachetzki, about the latest technology developments and the DTF market’s continuing evolution, assessing what it means for printer manufacturers and print service providers (PSPs) globally.

1. How does DTRX build on Brothers’ legacy in direct-to-garment (DTG) printing, and what specific technologies or lessens, if any, have been carried over?

Folker Stachetzki: The DTRX is the result of Brother's many years of experience in industrial printing, particularly in the field of DTG technology. One of the key strengths that Brother brings from its long experience is the seamless integration between the ink formulations and the print head technology, both of which were developed in-house. This synergy not only ensures high output quality but also exceptional reliability in printing performance.

Building on decades of expertise, the DTRX is designed to allow operators to focus on production rather than constantly worrying about machine maintenance. Its robust construction supports continuous, high-volume production, making it suitable for industrial-scale workflows. Leveraging proven technologies and Brother's experience with DTG and DTF, the DTRX offers a system that combines precision, efficiency and ease of use while delivering the durability and reliability expected by professional PSPs.

2. I understand that your main aim is to fill a gap in the market for reliable, consistent, industrial-grade performance. However, please elaborate on why your DTF technology is cutting-edge and outline what sets it apart from new DTF solutions from other market leaders.

FS: Brother has long been known for its reliable, low-maintenance industrial printers, and with the DTRX, we have transferred this philosophy to the DTF sector. During the development of the DTRX, we held extensive discussions with DTF users to gain a deep insight into the challenges they face in their daily operations. This user-oriented approach enabled us to develop a printer that directly addresses the most important weaknesses of the current market.

The biggest challenges of existing DTF solutions include long downtimes, slow production speed, maintenance-intensive operation, inconsistent colour quality, suboptimal hand feel of the prints and technical issues caused by the interaction between white ink and the print head. By focusing on these issues, the DTRX offers state-of-the-art performance through a combination of robust technology, optimised ink and print head integration and efficient workflows.

The printer delivers very high print quality in high-performance mode. The print speed and, consequently, the print quality can be adjusted and optimised in several stages to suit different production requirements, application types and customer-specific needs. This enables flexible performance depending on the workflow and operational priorities.

Compared to existing DTF solutions from other companies, the DTRX stands out because it has been specifically designed to reduce operator intervention, ensure consistent colour and print quality over long production runs and offer excellent tactile feel. Essentially, the DTRX fills the gap in the market for an industrial-grade, reliable and powerful DTF printer that meets the requirements of professional PSPs.

3. What testing and validation has been carried out on the DTRX, and how important are certifications to your customers and the broader garment decoration industry?

FS: The DTRX has undergone extensive testing in recent months, first at Brother's own facilities and then at selected customers' sites in real production environments. This rigorous approach ensures that the printer will perform reliably under a wide range of operating conditions, giving our customers confidence that it will meet the demands of industrial production.

Certifications are playing an increasingly important role in the garment decoration industry. They serve to protect the employees who operate the machines and ensure that end users are not exposed to any health or safety risks. By complying with recognised industry standards and obtaining relevant certifications, the DTRX demonstrates our commitment to occupational safety and consumer protection, which are key factors for professional PSPs when selecting equipment.

In addition to standard certifications such as European Conformity (CE), DTRX and its consumables are designed to support compliance with widely recognised sustainability and textile standards, including frameworks such as GOTS and OEKO-TEX.

4. What type of PSP is the DTRX aimed at, and is there a specific region where you expect demand to be higher for the printer?

FS: The DTRX was developed specifically for PSPs who work with medium-to-high production volumes and value consistent quality, reliability and efficiency in their operations. These are companies that need a reliable, industrial-grade DTF printer that delivers exceptional performance over long production runs while minimising downtime, maintenance and operational issues.

We are not focusing on a specific geographical region for the DTRX, as we are seeing strong interest from a variety of markets worldwide. More important than location is the nature of the requirements and expectations of the operators themselves. In all regions, professional PSPs are looking for solutions that offer durable, high-quality prints, high production speed, ease of use and consistently high performance.

Essentially, the DTRX is designed to meet the changing demands of the global DTF market. As the industry continues to grow and more companies adopt DTF technology, operators are placing increasing value on printers that combine industrial reliability with minimal maintenance. By addressing these priorities, the DTRX offers a solution that appeals to PSPs in different regions, enabling them to scale their production while at the same time ensuring the quality their customers expect.

5. At PRINTING United in October (2025), there were several powderless, jettable adhesive products on show. Is the DTRX compatible with these new, environmentally friendly chemistries, and does Brother plan to launch a similar liquid adhesive?

FS: The development of powder-free DTF solutions has been underway for some time, but the technology is still not ready for the market. Key challenges include ensuring consistent adhesion, maintaining wash resistance, achieving reliable colour quality and ensuring that the workflow is suitable for industrial production. Although these innovations are promising in terms of cleaner processes and environmental benefits, many of the current solutions have not yet proven themselves in real-world conditions and at high volumes.

At Brother, we are actively monitoring these developments and investigating possible approaches for the future. With DTRX, however, we have initially focused on offering a robust, reliable and industrial-ready solution that professional PSPs can rely on today for consistent, high-quality production. Powder-free DTF remains an exciting area of innovation, and Brother is eager to bring these advances to market once they meet the high standards our customers expect.

6. Can you expand on why seamless integration with existing workflows is so beneficial to your customers, and how this differs from cheaper solutions on the market?

FS: With DTRX, customers are not tied to a specific workflow. While the printer comes with free software, it is fully compatible with RIP solutions from other well-known providers, allowing operators to continue using established production workflows without the need for additional training. This seamless integration ensures that teams can maintain efficiency, consistency and productivity from day one.

In contrast, cheaper DTF printers often cause workflow issues due to inconsistent print quality, higher maintenance needs and limited software or material compatibility. These factors can disrupt operations and increase total operating costs, making lower-end machines less reliable for professional production environments.

7. DTF printers are not renowned for their longevity. If well-maintained, what is the expected lifespan of the DTRX?

FS: DTRX is a newly launched product; we cannot yet provide a definitive lifespan based on long-term field data. However, what we can say with confidence is that the DTRX has been designed fully in line with Brother’s longstanding philosophy of building durable, reliable and industrial-grade equipment. All testing conducted so far – both internally and with selected customers – indicates that DTRX meets these high expectations and is engineered for sustained performance when properly maintained.

To find out more about the technology, visit garmentprinter.global.brother/en-emea or click here to sign up to attend the company’s open house at its microfactory in Monchengladbach, Germany, on 22 January.

Have your say. Join the conversation and follow us on LinkedIn