Earlier this year, Rajant Corporation partnered with Mitsui USA to collaborate and bring IoT solutions to common customers in a bid to solve the advanced communications challenges of IIoT (Industrial Internet of Things), drones, V2V (vehicle to vehicle), and other autonomous applications, which work across a large range of vertical industries, textiles included.

Madelaine Cornforth talks to Dava Baumann, VP global marketing at Rajant Corporation, about how the company’s technology can enable mobile and real-time communications for industrial customers so they can streamline operations, increase revenue, and achieve real-time intelligence for better corporate decision making.

Rajant Corporation is the provider of pervasive, multi-frequency wireless solutions known as Kinetic Mesh networks. The company says its networks are unlike any other offering on the market today, providing fully mobile wireless broadband connectivity that is secure, scalable and has no single point of failure – a ‘living’ mesh solution that moves and evolves with connectivity demands. Baumann says: “With our patented InstaMesh, Rajant brings networks to life in that they are adaptable, agile, smart and dynamic, enabling industrial enterprises to deploy across a variety of market sectors and challenging physical and radio frequency (RF) environments.”

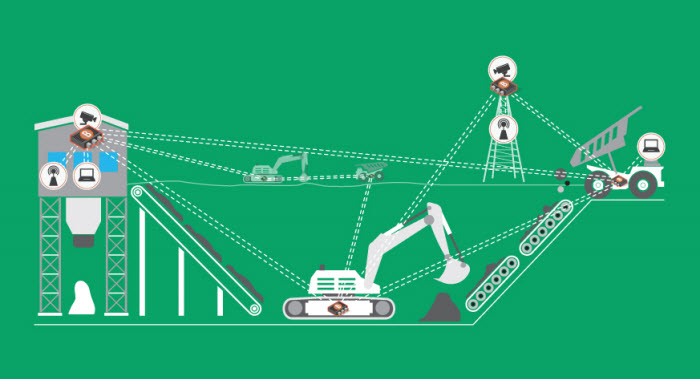

InstaMesh Network in the mining industry

InstaMesh technology is the routing software that allows Rajant’s wireless nodes, BreadCrumbs, to talk to each other in the most efficient way. For example, in a fully connected garment digital printing factory, sensors in the factory, the digital printing machines, cutting machines, finishing machines, computers and phones in the factory are assets, which need to communicate with each other to ensure that the printing is done in an efficient and fast way, while maintaining quality. When one digital printer is going to fail, for example, it can send a message to the other network assets to say it needs maintenance work, and will pass on the work to another machine, saving downtime and saving the machine from breaking fully as it has stopped itself from working at the first sign of a potential error. High functionality, easy-to-install BreadCrumb nodes work in concert with InstaMesh to enable voice, video and data communications that operate over a common wireless infrastructure. Hundreds can be quickly linked, self-configuring as part of a fully-mobile, high-bandwidth network.

Using a combination of BreadCrumb wireless network nodes and InstaMesh networking software, Rajant Kinetic Mesh networks employ any-node to any-node capabilities to continuously and instantaneously route data via the best available traffic path and frequency – for any number of nodes, all with extremely low overhead, the company states. Baumann says: “One of our most significant differences from that of traditional Wi-Fi is that we do not do hand-off, but rather make continuous multiple connections at all times. Traditional Wi-Fi must break a connection before making a new one, or they make one and then must break at some point before establishing a new connection. This distinction can negatively impact network performance, reliability, and mobility and would be more detrimental to a mission-critical network.

Rajant InstaMesh Network in the smart city

Rajant InstaMesh Network in the smart city

For Rajant, our ‘no hand off’ mode of connectivity means that critical communications can be accessed in real time. Also, Rajant Kinetic Mesh networks are inherently redundant in nature due to their ability to always establish connectivity to their neighbouring nodes and to our ‘no single point of failure’ system. Major benefits of our technology include total mobility, proven resiliency, maximum bandwidth utilisation, rapid scalability and extreme ruggedness and security, as Kinetic Mesh networks are proven to withstand the harshest conditions.” Being able to ensure difficult conditions is particularly important in the textile industry, where factories can be in harsh climates with poor connectivity.

Baumann says Rajant covers many industrial markets, but its main focuses are currently in mining, military, oil and gas, public safety, ports, transportation and Industry 4.0. “A number of our most prominent mesh networks can be found throughout the US, Canada, Australia, South Africa, Peru, Brazil, Mexico and Columbia,” she says. However, despite not yet breaking out into the textile industry, the company has seen a big uptake of interest from manufacturers. Baumann says: “Rajant technology can help textile manufacturers reach their strategic goals such as enhancing automation and precision processes which positively impacts efficient business operations.”

Textile companies are uniquely qualified to benefit from a mobile wireless network infrastructure like Kinetic Mesh technology. Baumann says: “Expect to see the demand for more of autonomous vehicles and robots grow dramatically as the Industrial Internet of Things (IIoT) expands. The IIoT will enable organisations to connect and gather data from thousands of devices, such as industrial machinery in textile practices. It will streamline operations, increase revenue, achieve real-time intelligence and improve productivity, without compromising quality. Robots and autonomous applications in textiles are highly effective at reducing human costs by taking over mundane, physically taxing or dangerous tasks and doing so while, improving efficiency and ensuring precision.”

Baumann claims that Rajant Kinetic Mesh networks empower those industries, such as textiles, which commonly have personnel and equipment that are remote, geographically dispersed and/or constantly on the move with private network capabilities that are fast, flexible, intelligent and made to optimise productivity. “For example, our technology is used in mining, where even brief periods of operational downtime can cause significant loss of revenue in short order [as it also can in textiles]. Kinetic Mesh networks enable operators to meet the continuous production and safety mandates called for in industrial and machinery environments with unwavering network availability.

By placing BreadCrumbs directly on machinery and applications, you can seamlessly link them together as part of an ever-moving Kinetic Mesh network – gaining real-time information from each asset’s applications on status, efficiency, maintenance needs and more. Industrial enterprises can also significantly streamline their processes since they are able to connect a myriad of sensors, cameras and other autonomous equipment that bring many benefits to their operations as a result of the real-time analytics now available from their network 24/7,” says Baumann.

The need for ironclad network infrastructure is critical to ensuring that autonomous vehicles and industrial robots operate flawlessly, according to Baumann. One of the most critical connectivity issues for autonomous applications is the ability to provide continuous, unbroken communications. “Our self-healing networks can provide that level of connectivity with our InstaMesh technology,” she adds. “The number and diversity of enterprises exploring our technology has grown exponentially as industries are finding that their network infrastructures are paramount to their operational and productivity success.”

However, security is paramount when it comes to implementing a network like this, particularly with the growing number of devices in a company. Baumann says Rajant has made an “extensive investment to provide a robust security platform with military-grade encryption. As encrypted information flows through the mesh, it stays encrypted all the way through and is not decrypted until it is delivered to its final destination. Our encryption also helps to protect communications from attacks that try to analyse traffic and see which nodes are communicating with other devices. Our numerous military deployments are a testament to the power of our security functionality.”

Have your say. Tweet and follow us @MCornforth_WTiN and @WTiNcomment

RELATED ARTICLES

-

Uniting the industry to achieve green change

- Joseph Link

- WTiN

-

Caldera’s new streamlined RIP portfolio

- Caldera

- WTiN