Researchers at the University of Bayreuth, Germany, have partnered with scientists from Donghua University and Nanjing Forestry University, China, to develop new nonwoven materials that are electrically conductive as well as flexible and breathable. This paves the way for comfortable high-tech clothes which, for example, could convert sunlight to warmth, supply wearable electronic devices with electricity, or contain sensors for fitness training.

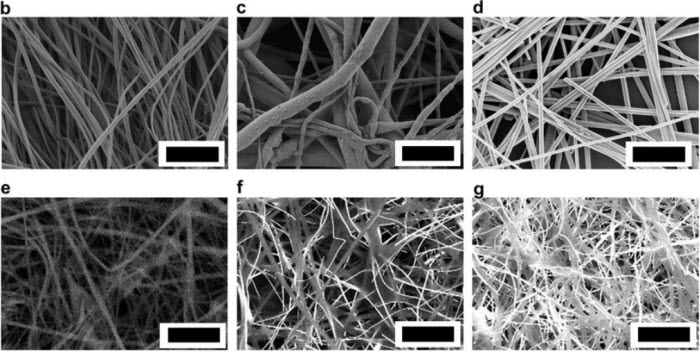

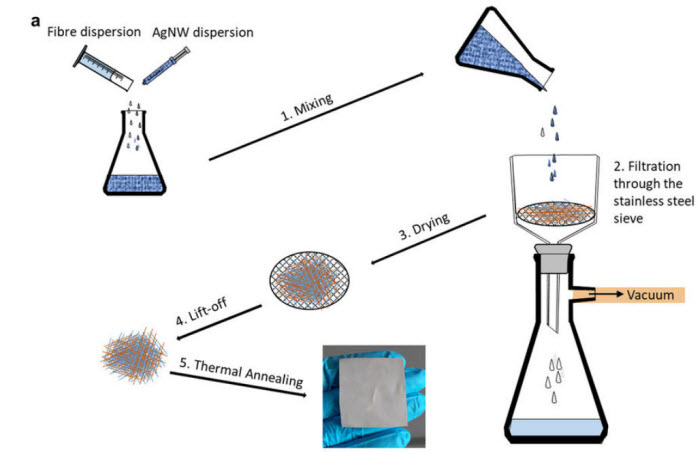

Preparation and morphology of PANPCLAgNW nonwovens prepared by the wet-laid process

Preparation and morphology of PANPCLAgNW nonwovens prepared by the wet-laid process

According to the researchers, metal-like conductivity in polymer nonwovens has not been achieved until now due to the limitation of existing processing techniques. The collaborative team, led by Andreas Greiner from the University of Bayreuth, demonstrates that by reducing the percolation threshold significantly with a wetlaid method, silver nanowire (AgNW) and polymer composite nonwovens show high electrical conductivity of 750,000S/m at only 3.4 vol% loading of silver. It can be attributed to the homogenous distribution of the silver nanowires in the electrospun polymer fibres.

Other advantages of the wetlaid process are that composite nonwovens could be fabricated by a roll-to-roll process and many other additives could be added for multifunctionality.

Nonwovens composed of short electrospun PAN nanofibres and PCL microfibres were prepared with different amounts of AgNW (PAN/PCL/AgNW nonwovens) by the recently established wet-laid process, as illustrated schematically in Figure 1.

Figure 1

In addition, the high conductivity of the composites is almost fully resistive to bending. These features enable the use of the conductive composite nonwovens in various flexible, lightweight and economic applications. For instance, they can act as Joule heaters at a constant voltage of 1.1 V, which is in the range of portable devices.

According to the researchers, the increase in length of AgNW increases the electrical conductivity of the composite significantly. The design of AgNW will provide more opportunities for further increase of the conductivity of the nonwovens. The concept of conductive composite nonwoven preparation should be widely applicable to other nonwovens based on short micro- and nanofibres prepared by the wetlaid process.

Consequently, future work will focus on the implementation of other shape-anisotropic conductive additives in wetlaid micro-fibre and nanofibre nonwovens, the translation of the process to 3D-shaped objects, and its application as electrodes in textiles, capacitors, batteries, functional textiles, and as a basis for sensor devices.

To learn more about the study, click here.

Have your say. Tweet and follow us @FHaran_WTiN and @WTiNcomment

RELATED ARTICLES

-

Advanced temperature-regulating fabric

- Outlast Technologies

- WTiN

-

Sanitized and Rudolf distribution partnership

- Sanitized

- WTiN

-

James Heal achieves industry standard

- James Heal

- WTiN