Sportswear brand Nike has published a patent outlining a method for 3D printing both the structure and colour of a product, with a focus on footwear.

Entitled ‘Color density based thickness compensation printing’, the patent concerns management of the thickness of a three-dimensional object, as well as its colour, which is thus ‘assigned a colour density.’ The patent says that in instances “where a colour density is used, a colour density may correspond with any volume of print material.”

The thickness of the product is independent from the colour thickness, it continues, but despite this the thickness of the structural layer is determined based on the colour thickness and the target thickness of the overall product. “Increasing a colour density may result in a corresponding increase in a volume of print material within the fixed area, thereby increasing a colour thickness,” it states.

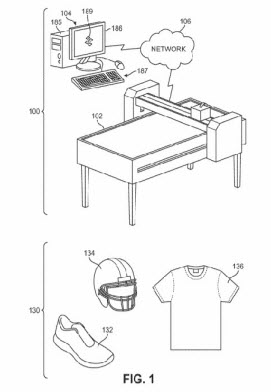

The patent figures portray a CMYK jetting format and Figure 1 shows a ‘schematic diagram of a printing system.’ Later, the patent clarifies that the system “includes a print controller and a printing device. The print controller is configured to receive a colour for each pixel […] prepare colour print instructions based on the colour […] and receive a thickness for each pixel of the plurality of pixels.”

Moreover, the patent states that water-based inks may be used for CMYK printing purposes and it refers to another patent – Miller (US Patent Publication Number 2015-0002567), published in January 2015 and titled Additive Color Printing – which it states discloses an example of the printing device referred to here.

While the context of the patent focuses on articles of footwear, the patent says the technology can be equally applied to any article of clothing, apparel, or equipment that includes an element of three-dimensional printing. This includes hats, shirts, jackets, socks, shorts, athletic support garments, gloves, nonwoven materials and other items.

The patent also states that technology takes into account the number of layers needed to make the product, the number of passes of the print heads, and enables control of the height of the print head from the surface in question depending on the printing stage.

Printed layers are said to have both aesthetic and functional purposes and provisions can be made so that a portion of a colour layer and a portion of a structural layer are dispensed during a single pass of the print head configuration. Structural layers and colour layers can vary in thickness and this is programmed for the particular product being manufactured.

Have your say. Tweet and follow us @WTiNcomment

RELATED ARTICLES

-

Academia’s relationship with industry

- Abigail Turner

- WTiN

-

Strategic approach to boost transfer paper sales

- Joseph Link

- WTiN

-

WTiN Weekly Review: 2 July 2025

- Abigail Turner

- WTiN

-

News Release

Bluesign revision of chemical reference lists